모든 재료 취급 솔루션

-

무선 네트워크를 이용한 모터 온도 모니터링 및 제어

무선 네트워크를 이용한 모터 온도 모니터링 및 제어

I/O 전송 케이블을 설치하는 대신 10~30V DC 전원 SureCross 노드 및 Banner T-GAGE 온도 센서를 사용하십시오. 호스트 제어 시스템을 사용할 때 SureCross 게이트웨이는 센서 내의 온도 설정 포인트와 관련된 디지털 출력을 사용하여 공장 제어실로 온도를 전송합니다. 이 온도에 따라 모터의 전원이 켜지거나 꺼집니다. Gateway Pro를 무선 마스터 장치로 사용하는 경우 모터가 예상된 매개변수를 벗어나 가동되면 데이터가 기록되고 유지 보수 담당자에게 경보가 전송됩니다.

-

캐비닛 제조사의 온도 및 습도 조절

캐비닛 제조사의 온도 및 습도 조절

대형 캐비닛 제조사는 대규모 생산 시설에 있는 많은 방의 온도 및 습도를 모니터링하고 제어해야 합니다. 공장 전체의 수동 환경 측정은 일주일 내내 주기적으로 수행되었습니다. 이러한 수동 판독은 정보의 단면만 제공하였으며 데이터 수집에 3시간 이상이 걸렸습니다. 고객은 공장 환경을 제어하는 데 사용할 수 있는 정확한 실시간 정보를 가지고 있지 않았습니다. 이 정보를 수동으로 수집하고 송풍 시스템을 제어하는 것은 시간을 낭비하는 것이었고, 이로 인해 보관 중인 목재, 진행 중인 작업 및 완성된 캐비닛을 손상하는 오류가 발생했습니다.

-

기계 모니터링/전체 장비 효율성

기계 모니터링/전체 장비 효율성

• Expand available data beyond local indication • Gather information necessary to react quickly • Drive efficiency improvements based on data previously unavailable

-

감독자의 스테이션에서 장비 모니터링

감독자의 스테이션에서 장비 모니터링

• 기계 상태를 한 눈에 파악할 수 있는 표시등 제공 • 광범위한 장치로 기계 상태 정보 보내기 • 문자 메시지 또는 이메일을 통해 직원 및 감독자에게 심각한 상태 알림

-

기계 제어반 내에서 환경 모니터링

기계 제어반 내에서 환경 모니터링

• 기계 성능 및 가동 시간에 영향을 미치는 심각한 문제로 발전하기 전에 사소한 문제를 식별합니다. • 원격 위치에서 환경 데이터에 액세스 • 문자 메시지 또는 이메일을 통해 작업자에게 심각한 상태 알림

-

예측 및 예방적 유지보수용 상태 모니터링

예측 및 예방적 유지보수용 상태 모니터링

Identify machine problems before they cause serious damage or unplanned downtime and alert staff of changes in condition via text message or email as well as provide at-a-glance local indication of machine status.

-

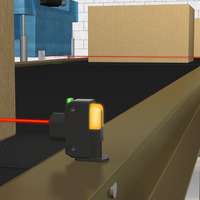

High Speed Package Profiling with Laser Sensors

High Speed Package Profiling with Laser Sensors

3 Apr 2019A laser measurement solution enables high-speed package sorting in order fulfillment applications and helps drives failure rates down—ultimately saving costs and maximizing profits.

-

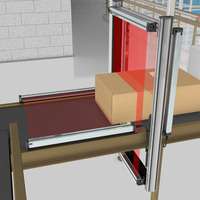

Safeguarding Access Points to a Depalletizer

Safeguarding Access Points to a Depalletizer

An LS Series safety light curtain with a mute arm kit in T-configuration combined with an XS26 Series safety controller is an easy-to-implement solution that protects staff from potential hazards without disrupting the flow of pallets to the depalletizer.

-

팔레트 운반 컨베이어 보호

팔레트 운반 컨베이어 보호

Pallet transfer conveyors are used to move heavy loads to the shipping area. Both the pallets and the conveyor pose risks for accident and injury and must be safeguarded. An SX5-B safety laser scanners safeguards the loading and unloading stations on the conveyor and enables a continuous flow of pallets through the system.

-

바코드 판독

바코드 판독

ABR Series barcode readers can be used to solve track and trace applications, offering increased resolution to read smaller codes, over a larger target area, and at greater distances. Polarization is now available in both 1.3 MP and 2 MP ABR 7000 models for improved performance on targets with reflective surfaces or where glare is present. Our highest resolution camera, the VE is also available in only-barcode reading models, as well as the original vision camera-only model. This makes our VE series is the highest-resolution barcode reader in our portfolio, designed to better solve complex applications.

-

복수 1D 및 2D 바코드 판독

복수 1D 및 2D 바코드 판독

Barcode position can change with the location of each box on a conveyor and the height of the boxes can vary. An ABR 7000 barcode reader decodes multiple 1D and 2D barcodes over a large area in a single inspection, regardless of position or orientation.

-

포장 과정 전반에서 제품 추적

포장 과정 전반에서 제품 추적

Barcodes used to track packaged produce through the supply chain contain important product information that must be verified at multiple points during packaging. An ABR 3000 barcode reader ensures that the barcode on each package is present and correct.

-

주문 이행: 넓은 선반

주문 이행: 넓은 선반

각각의 넓은 선반에 재귀반사 모드의 일체형 EZ-LIGHT PVD Pick To Light가 장착되어 있고, 범위는 최대 2m입니다. PVD가 작업자가 배송할 지도를 선택할 용기를 비춥니다.

-

주문 이행을 위한 용기 선별

주문 이행을 위한 용기 선별

책 포장 창고에는 각각의 책 상자 위의 선반에 일체형 EZ-LIGHT PVD pick-to-light 센서가 장착되어 있습니다. 작업자는 포장 명세서에 지정된 각 책의 수량을 선택하여 주문을 입력합니다. 작업자가 책을 선별한 상자를 쉽게 찾을 수 있도록 해당 상자 위의 PVD가 밝게 표시됩니다. PVD는 상자에서 작업자 손을 감지하여 제목이 선택되었는지 확인합니다.

-

대규모 스테이션에서 라이트 안내 키트 구축

대규모 스테이션에서 라이트 안내 키트 구축

Manual kit building at large stations can be time-consuming and subject to human error, especially if storage racks are difficult to navigate. The PTL110 series pick-to-lights are scalable for large systems and highly versatile to complete numerous tasks.

-

최종 조립 및 주문 처리를 가속화하는 Pick-to-Light

최종 조립 및 주문 처리를 가속화하는 Pick-to-Light

Learn how a golf equipment manufacturer recently used PTL110 pick-to-light devices to simplify and accelerate their final product assembly and order fulfillment processes.

-

Improving Productivity with Pick-to-Light Products

Improving Productivity with Pick-to-Light Products

Learn how eFlex Systems empowered a hydraulic pump manufacturer with its turn-key platform and Banner's PTL110 pick-to-light devices to improve productivity and reduce errors in their assembly processes.

-

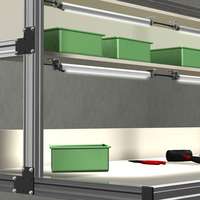

작업대용 고품질 LED 라이트

작업대용 고품질 LED 라이트

Banner’s WLB32 Industrial Light Bar is ideal for workstations. With a Hi/Lo/Off switch, operators are able to control the lighting level and are able to switch the LED light bar off when they are done. The WLB32 provides workers high brightness with even light output and enables numerous tasks in a workstation, including working on a computer.

-

Highly Bright Illumination in Workstations

Highly Bright Illumination in Workstations

Banner’s WLS28 Work Light Strips with ON/OFF switches provide an energy-efficient solution for illuminating work areas and enclosure interiors with intense, long-lasting light. These LED lighting strips provide even, extremely bright illumination, and can easily fit in limited space setups. The work lights can be plugged into any local power source for simple operation.

-

Low-Bay LED Lighting

Low-Bay LED Lighting

The heavy-duty, energy-saving WLB92 from Banner Engineering provides an extremely bright lighting solution that provides consistent lighting across a warehouse. Since the LED factory light is so bright and gives a uniform output, fewer lights are needed in total, helping reduce the overall cost of lights and installation time.

-

지게차 안내 조명

지게차 안내 조명

The WLS27 Pro with discrete control and configured by Banner’s Pro Editor software is one of two new models of the WLS27 Pro series strip light. It now includes programmable RGBW LEDs for use in illumination, indication and inspection applications. Learn how the configurable WS27 Pro provided forklift guidance for warehouse operators.

-

산업용 자동문의 고휘도 LED 표시

산업용 자동문의 고휘도 LED 표시

Star Equipment uses Banner's WLS27 multicolor LED strip lights with EZ-STATUS™ with their automated industrial doors for safer, more efficient movement in the workplace.

-

컨베이어 시스템의 작업자용 표시기

컨베이어 시스템의 작업자용 표시기

Learn how a facility used the K30 Pro Touch Button to improve operator control and guidance.

-

박스 포장기 상태 표시

박스 포장기 상태 표시

A solution was needed to better indicate a variety of complex statuses coming from a labeling machine. Banner's CL50 Pro column lights are an effective way to provide at-a-glance status indication.

-

분류 컨베이어 위의 상세 검사

분류 컨베이어 위의 상세 검사

In large distribution facilities, sortation trays deliver products to the proper bin for correct shipment. Before sorting can begin, each tray needs to be empty so that items can be placed on the conveyor and sent to the next location. The 5mp VE Smart Camera recognizes very fine levels of detail and can detect items of almost any size, confirming the presence or absence of items on the trays.

-

표시 기능이 포함된 창고 차량 탐지

표시 기능이 포함된 창고 차량 탐지

Vehicle detection at loading docks is complicated because sensing solutions are exposed to the elements and need to recognize a wide variety of surfaces. Rugged ultrasonic sensors work well to accurately detect the surfaces of delivery vehicles regardless of the material. Pairing with bright LED indication creates unmistakable operator guidance.

-

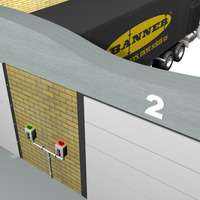

실외 도킹 스테이션의 차량 감지 및 표시

실외 도킹 스테이션의 차량 감지 및 표시

Detecting trucks and signalling arrival, wireless communication.

-

적재 도크에서의 입고 및 출고 상태 표시

적재 도크에서의 입고 및 출고 상태 표시

In a recent material handling application, facility managers needed to find a solution that would alert them to the status of trailer capacity at loading dock doors in real-time.

-

연장형 연결 컨베이어

연장형 연결 컨베이어

Banner는 컨테이너 내에서 판지 상자와 제품의 손상을 최소화하기 위해 감지 솔루션 및 산업용 LED 조명 솔루션을 제공합니다. 배경 억제 기능이 있는 Banner의 QS18FF는 응답 시간이 850마이크로초이며 최대 범위가 100mm로 고정되어 포장물/화물을 쉽게 감지하고 연장형 컨베이어가 상자를 찌그러뜨리지 않도록 합니다. Banner의 WLB32는 적절한 밝기를 보장하는 루멘 출력이 높은 AC 및 DC 버전으로 제공되는 비용 효율성이 뛰어난 LED 조명 솔루션입니다.

-

셔틀 토트 위치 선정

셔틀 토트 위치 선정

Q20 WORLD-BEAM 편광 레트로 센서는 멀티셔틀의 레일에 장착되어 제품이 안전 구역 내에 유지되고 "안전 구역"을 벗어나지 않도록 정확하게 배치되는지 확인합니다. Q20 센서는 비용 효율적이며 정확하게 존재와 배치 위치를 감지할 수 있으므로 창고 환경에 이상적이며, 소형이고 설치하기 쉬우므로 해당 분야에 적합한 견고한 제품입니다. Q20 센서의 거리 범위는 최대 4 m이며 노이즈 내성과 크로스토크 방지 기능이 있어 작업자가 사용하기 전에 시스템을 테스트할 수 있습니다.

-

Wireless Forklift Signaling

Wireless Forklift Signaling

Banner’s Q45 wireless call sensor communicates to a wireless DX80, signaling that forklift drivers can remove the completed pallet for shipping. This helps keep the conveyor clear, keep it moving faster and leads to more productivity. Since forklift drivers are being called to action more quickly, it allows for more productivity.

-

만재 토트 표시 및 확인

만재 토트 표시 및 확인

시각적 관리 기능을 적절하게 식별하고 활용하기 위해서는 자루가 만재된 상태에서 센서가 실행되어 K50 터치 버튼에 토트가 만재되었음을 나타내는 적색 표시등을 켜라는 신호를 보냅니다. K50 터치 버튼은 작업자에게 자루를 치우고 빈 자루로 교체해야 함을 시각적으로 알립니다. 자루에 포장물을 더 적재할 수 있다고 표시하기 위해 작업자가 인체 공학적 K50 터치 버튼을 누르면 표시등이 다시 녹색으로 바뀌어 자루에 포장물을 적재할 준비가 되었음을 알립니다.

-

출구 활송 장치 걸림 표시

출구 활송 장치 걸림 표시

Banner의 Q30FF600 배경 억제 센서는 제품이 출구 활송 장치로 진입할 때 확인해 분류 시스템에서 제품이 분리되고 제품 활송 장치에서 걸림이 발생하지 않았는지 검사합니다. Q30FF600은 감지 범위가 최대 600mm이며, 이는 많은 활송 장치에서 표준 너비입니다.

-

존재 및 부재 품목 감지

존재 및 부재 품목 감지

VE 시리즈 스마트 카메라는 물체의 존재 또는 부재를 감지하는 데 이상적인 솔루션입니다. 5MP 해상도의 카메라를 탑재하여 물체를 정밀하게 감지할 수 있습니다. VE 시리즈는 신속한 제품 전환을 지원하므로 비용이 많이 소요되는 가동 중단을 줄여줍니다. 견고한 금속 하우징과 옵션 렌즈 커버를 지원하는 VE 시리즈는 열, 진동, 수분이 있는 극한 환경에서 사용할 수 있습니다.

-

정렬 자동 유도 스테이션

정렬 자동 유도 스테이션

S18-2 재귀반사 센서는 자동 유도 컨베이어 스테이션을 따라 효율적인 장거리 감지 기능을 제공하고, 편광 센서는 잘못된 트리거를 줄임으로써 표면이 반짝이는 표면에 유용합니다. S18-2 재귀반사 센서는 배럴 마운트 방식의 경제적인 센서로 검증을 위해 컨베이어를 따라 쉽게 설치할 수 있고 재귀반사, 투과 빔, 확산 또는 고정 필드 모델로 제공됩니다.

-

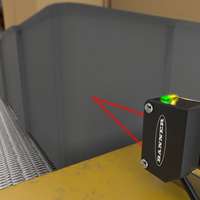

스태커 크레인 위치 선정

스태커 크레인 위치 선정

Banner의 Time-of- Flight (ToF) LT7 레이저 센서는 쉽게 정렬할 수 있도록 눈에 잘 띄는 적색 레이저 스팟과 함께 250m의 긴 범위를 제공합니다. 필요한 범위에 따라 확산 또는 역반사 ToF 레이저 센서를 사용할 수 있습니다. 역반사 LT7 레이저 센서의 최대 범위는 250m이고, 확산 LT7 레이저 센서는 최대 10m의 장거리 배경 억제 기능을 제공합니다.

-

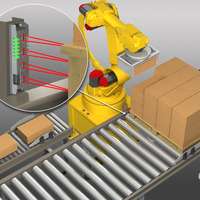

Carton Dimensioning

Carton Dimensioning

Banner’s EZ-ARRAY measuring light curtains detect items as small as 5 mm wide with an edge resolution of 2.5 mm, and have high excess gain for detecting opaque objects. These features allow for reliable detection and measurement of packages that pass through the light curtains. The total number of beams blocked for each pair indicates the size, which is sent to a sorter as an analog signal. A PLC then diverts each carton to the appropriate storage location.

-

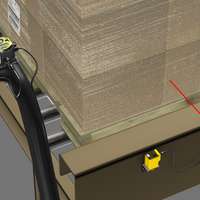

정확한 팔레트 감지

정확한 팔레트 감지

Banner의 PVD100은 형상이 일정하지 않은 경우에도 조정 없이 팔레트를 정확하게 감지하는 맞춤형 솔루션입니다. 간단하게 사용할 수 있는 이 다용도 라이트 스크린은 빔 패턴이 넓어 정렬이 간단하고, 컴팩트한 디자인 덕분에 머신에 쉽게 내장하거나 라인에 직접 장착할 수 있습니다. PVD100 라이트 스크린 감지 솔루션은 감지 높이가 100mm, 스캔 범위가 2m이고, 눈에 잘 띄는 빨간색 및 녹색 LED 조명이 작업 및 작동 상태를 나타냅니다.

-

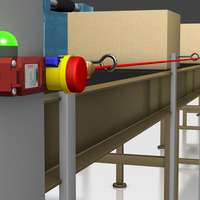

Emergency Stop Buttons on a Conveyor

Emergency Stop Buttons on a Conveyor

Banner’s 30 mm mount E-Stop buttons work well in this type of application because they have an illuminated base that turns from yellow to flashing red when actuated. The red flashing illumination of the E-stop button visibly alerts operators which button was pressed so they can quickly and easily fix the problem to reduce down time and only reset the button that was activated.

-

Traffic Control at Loading Docks

Traffic Control at Loading Docks

EZ-LIGHT Traffic Lights are mounted at each bay to visually signal to drivers when they have permission to back into the loading dock. The lights are preassembled, with up to three indicators and three colors in one housing, making them cost effective and easy to install. Traffic Lights are an ideal solution for outdoor applications, with intense levels of light output and included sun shields.

-

운반 카트의 케이블 교체

운반 카트의 케이블 교체

일반적으로 운반 카트는 작업에 전도체 케이블을 사용하는데, 시간이 흐르면 이 케이블이 끊어져 생산 지연을 일으키거나 유지 관리 비용이 증가합니다. 운반 카트를 무선으로 제어하면 이러한 문제가 줄어듭니다.

-

Pallet Transfer Safeguarding

Pallet Transfer Safeguarding

Due to the dangers associated with a full pallet transfer, horizontal area guarding is needed in order to maximize productivity of packaging while protecting operators from the hazardous motion of a machine.

-

Detecting Pallets with Irregular Loads

Detecting Pallets with Irregular Loads

An ultrasonic sensor will provide reliable pallet detection. Ultrasonic sensors emit sound waves and “listen” for the return echo of the sound wave bouncing off the target. The sensor can be taught a reliable background, in this case the conveyor, and will listen for sound waves returning from the conveyor. Any object getting between the sensor and the conveyor will be detected, causing the output to switch.

-

자동 보관 및 검색 시스템

자동 보관 및 검색 시스템

SureCross FlexPower™ 노드와 저전력 센서가 결합되면 기존의 자동 보관 및 검색 시스템(AS/RS) 크레인과 즉시 통합되는 휴대용 모니터링 시스템을 구축할 수 있습니다. Banner의 신뢰할 수 있는 무선 솔루션과 고유한 전원 관리 기능을 결합하면 AS/RS 크레인에 간단한 모니터링 애플리케이션을 여러 개를 구축할 수 있습니다. FlexPower 배터리 팩은 수년 동안 노드와 최대 4대의 저전력 센서에 작동 전원을 공급할 수 있습니다. 모터 또는 중요한 베어링 온도를 모니터링하기 위한 열전대가 여러 개 장착된 FlexPower 노드를 사용하여 예방적 유지 관리 문제를 해결할 수 있습니다. 게이트웨이(시스템 컨트롤러)의 통신 출력을 사용하면 이력 로그 또는 추세를 생성해 장치가 최대 성능으로 작동 중인지 확인할 수 있습니다. 각 통로 끝에 달린 EZ-LIGHT™ 표시등은 크레인의 움직임을 직원에게 알릴 수 있습니다. 이 양방향 모니터링 시스템은 새롭게 구성하거나 많은 비용이 드는 가동 중단 시간 없이 크레인이 작동 중임을 직원에게 알릴 수 있는 간단한 방법입니다.

-

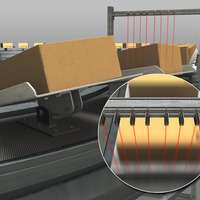

Carton Sizing

Carton Sizing

Cartons moving on a conveyor pass between three pairs of EZ-ARRAY measuring light curtains. The total number of beams blocked for each pair indicates the size, which is sent to a sorter as an analog signal. A PLC then diverts each carton to the appropriate storage location.

-

컨베이어 걸림 감지

컨베이어 걸림 감지

컨베이어 모서리 주위에서 포장 상자 또는 토트백이 걸리면 컨베이어가 휘는 지점에 장착된 WORLD-BEAM QS18 범용 전압 센서가 경보 장치 또는 PLC에 물체가 걸렸다는 정보를 전달해 직원에게 걸림이 발생했음을 알립니다.

-

Retrofitting for Pallet Detection

Retrofitting for Pallet Detection

WORLD-BEAM QS18 Universal Voltage sensors are mounted along a conveyor to detect the presence and position of passing paletts. These sensors can be connected to either AC or DC power, allowing them to operate in large conveyor applications already using AC power without requiring a separate power supply. In addition to the universal voltage, this sensor also has a popular 18 mm barrel shape, multiple mounting options, and a rugged IP67 housing to withstand harsh environments. Having multiple power and mounting options in a single sensor allow for a quick and easy retrofit on the line.

-

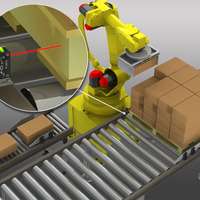

Load Station Pallet Detection

Load Station Pallet Detection

WOLD-BEAM Q20 확산 센서가 배치되어 팔레트가 있는지 감지합니다. 팔레트가 제자리에 놓이면 출력은 로봇에 적재를 시작하라는 신호를 보냅니다.

-

시설 기능 모니터링

시설 기능 모니터링

Banner의 무선 솔루션은 여러 게이트웨이를 각각의 노드에 연계할 수 있으므로, 모든 배선을 없애고 유연한 장착 옵션을 제공할 수 있습니다. 게이트웨이와 노드의 무선 구조를 통해 시설 전반에 걸친 핵심 I/O 통신이 처리됩니다. 다수의 무선 제품을 사용하지만, Banner 무선 통신 시스템은 효율적이고 크로스토크 간섭이 없으며 IT 부서 업무에 방해가 되지도 않습니다.

-

Emergency Indication on Conveyors

Emergency Indication on Conveyors

Banner’s RP-LS42 safety rope pulls line conveyors as a way to indicate emergencies and immediately shut down conveyors. If a rope pull is used during an emergency, it can be difficult to locate exactly where it was pulled. A K30 indicator light can be paired with the rope pulls in order to provide indication as to where the rope was pulled. This allows for quick and easy indication of where an emergency occurred, helping to return to normal operations as fast as possible.

-

AC 전원 컨베이어 위의 물체 감지

AC 전원 컨베이어 위의 물체 감지

WORLD-BEAM QS18 범용 전압 센서를 AC 또는 DC 전원에 연결하면 별도의 전원 공급 장치가 없어도 AC 전원을 이미 사용하고 있는 대형 컨베이어에서 작동할 수 있습니다. 견고한 소형 하우징 및 여러 장착 옵션 덕분에 WORLD-BEAM QS18 범용 전압 센서는 다양하게 활용할 수 있습니다.