Reliable Detection of Transparent Bottles on Conveyor

A machinery company needed a sensor able to consistently detect clear PET bottles at multiple points.

Universal housing design with 18 mm threaded lens an ideal replacement for hundreds of other sensor styles

QS18 Series All Purpose Photoelectric Sensor

A machinery company needed a sensor able to consistently detect clear PET bottles at multiple points.

A leading manufacturer of labeling equipment offers high-speed shrink sleeve label applicators designed to process 800 bottles per minute. To maximize the machine’s performance potential, the company wanted to install sensors capable of consistent detection and output for high-speed bottling.

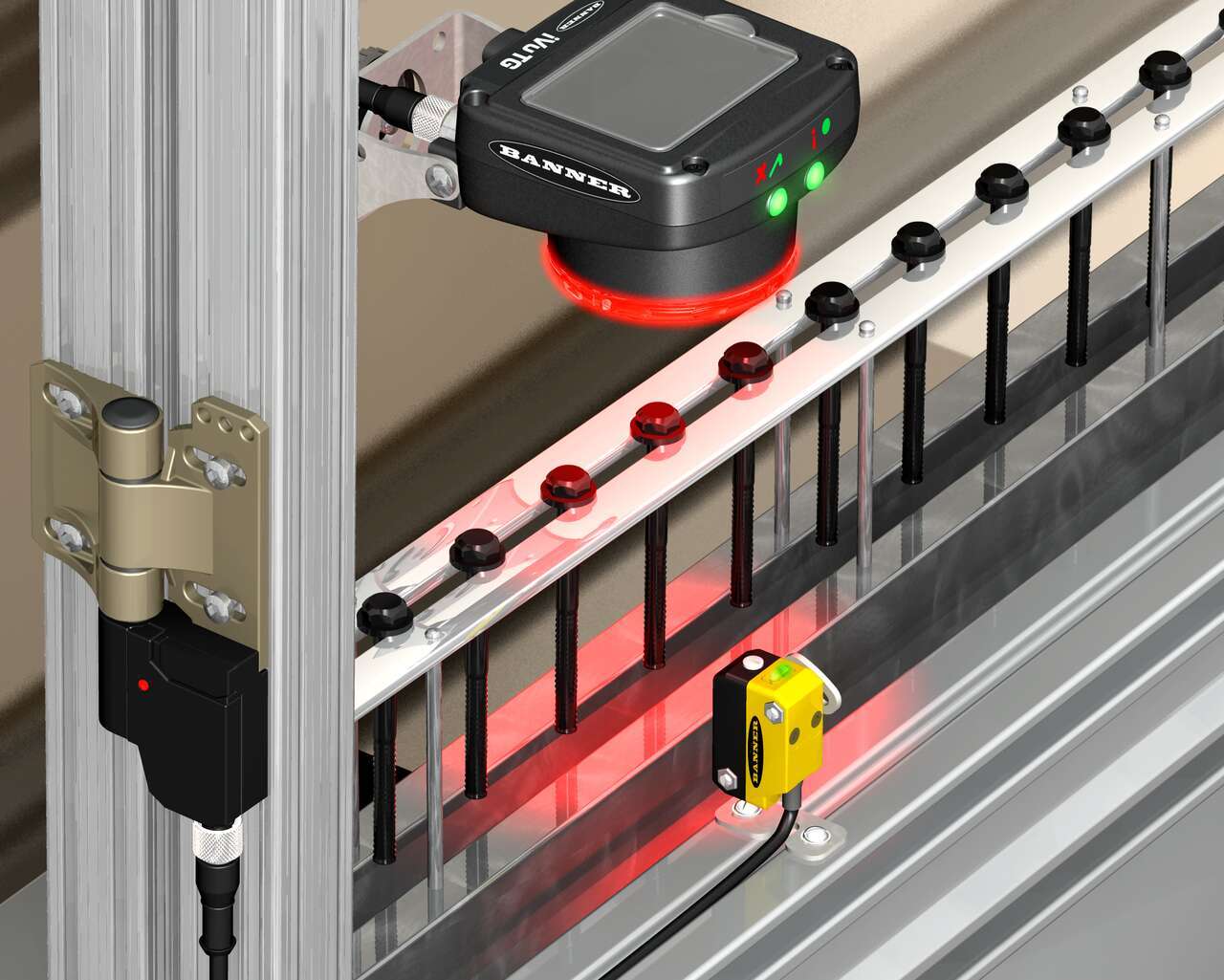

A solution was needed to better indicate a variety of complex statuses coming from a labeling machine. Banner's CL50 Pro column lights are an effective way to provide at-a-glance status indication.

WORLD-BEAM QS18 Universal Voltage sensors can be connected to either AC or DC power, allowing them to operate in large conveyor applications already using AC power without requiring a separate power supply. The robust, compact housing and multiple mounting options add to the versatility of WORLD-BEAM QS18 Universal Voltage sensors.

With a narrow beam that projects a small bright spot, the QS18LLP laser, polarized, retro-reflective sensors provide precise position control when triggering various devices. In this application, the QS18LLP is able to correctly detect the glossy carton as it travels down the conveyor—without proxing—and trigger the ink jet printer to print the date/lot code on the carton. The second sensor triggers the P4 OMNI to inspect the date/lot code and verify it is legible and correct.

Banner sensors are positioned above a conveyor inspecting each passing box for missing chocolates. When a passing box breaks the trigger beam created by a pair of Q12 opposed-mode sensors, an array of QS18AF sensors mounted above the box inspect each location for missing chocolates. When a box containing the wrong amount of chocolates is detected, an output signal is relayed to a main controller at the packaging line warning of the failed condition.

Banner’s WORLD-BEAM QS18LP laser sensor accurately inspects every carton that passes on the conveyor, ensuring the robot is triggered to load cartons into the package. With a visible laser sensing beam, the QS18LP provides precise position control, which is ideal to ensure accurate counting of cartons at a close range. The rugged QS18LP is also ideal for confined spaces and is easily set up along a conveyor for accurate sensing. With highly bright LEDs, operating status is visible from 360⁰.

In this illustration, precision machined bolts have just come out of the feeder bowl and are moving down the feeder bowl rail, conveying to the next automated step. As they move down the rail, a WORLD-BEAM QS18 detects the bolt and sends a triggering signal to an inspection sensor, the iVu Image Sensor. The iVu is configured to detect a flaw in the flange, irregular shape of the bolt head, or other flaws that might be present.

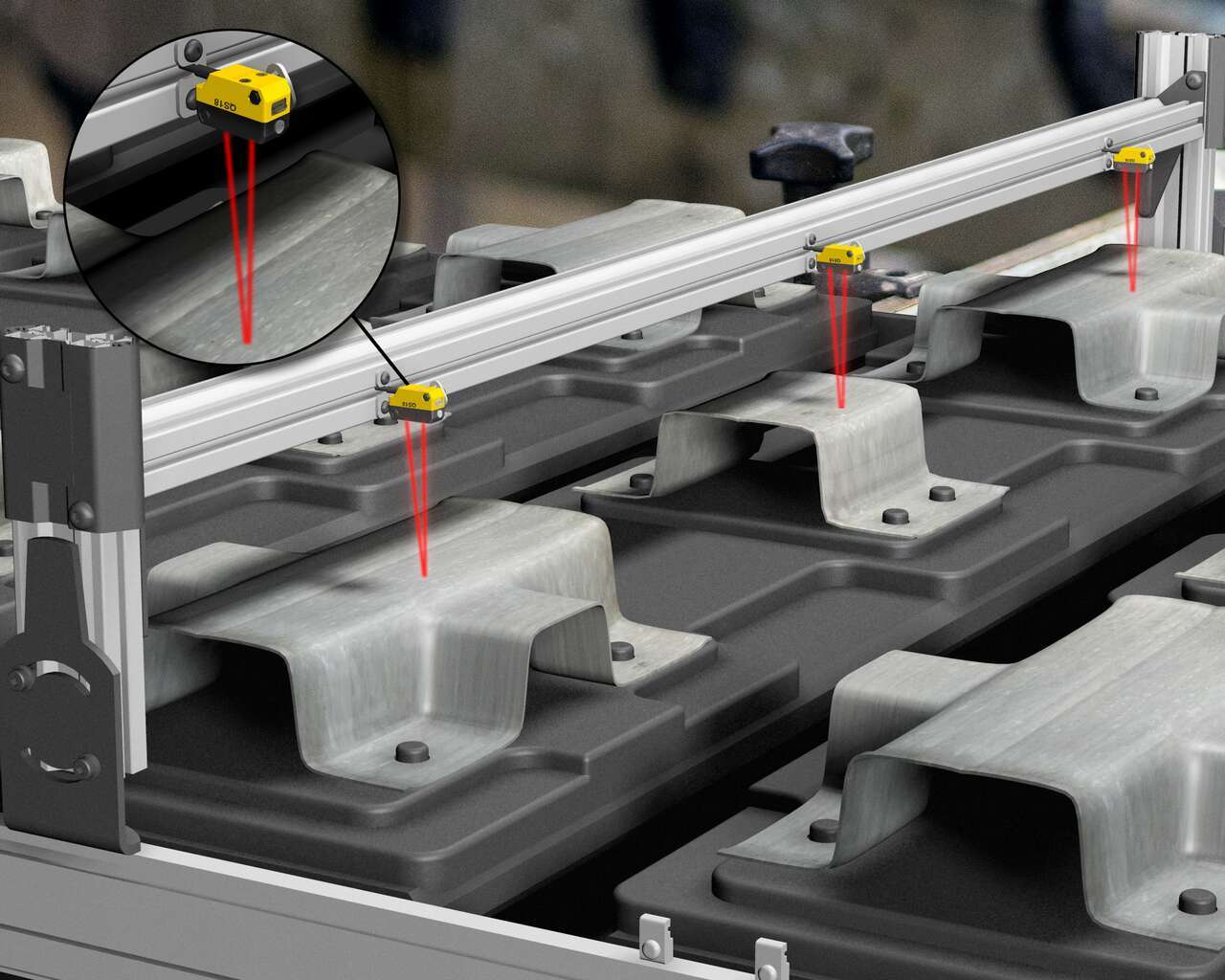

The WORLD-BEAM QS18 adjustable field background suppression sensor is an excellent choice for this part-in-place application, requiring a three-inch scanning distance. With the combination of high-gain characteristics, sharp adjustable cutoff and a forgiving visible red light beam this sensor ensures longevity in this harsh environment.

Using a sensor in clear object sensing mode to ensure proper staging of plastic trays during denesting process.

Sensor solutions to detect reflective food wrappers such as Mylar with conveyor belt presence verification, utilizing foreground suppression.

Sensor solutions to detect translucent bottles in a range of shapes, sizes, colors and contours in a high-speed air conveyance system, identifying gaps.

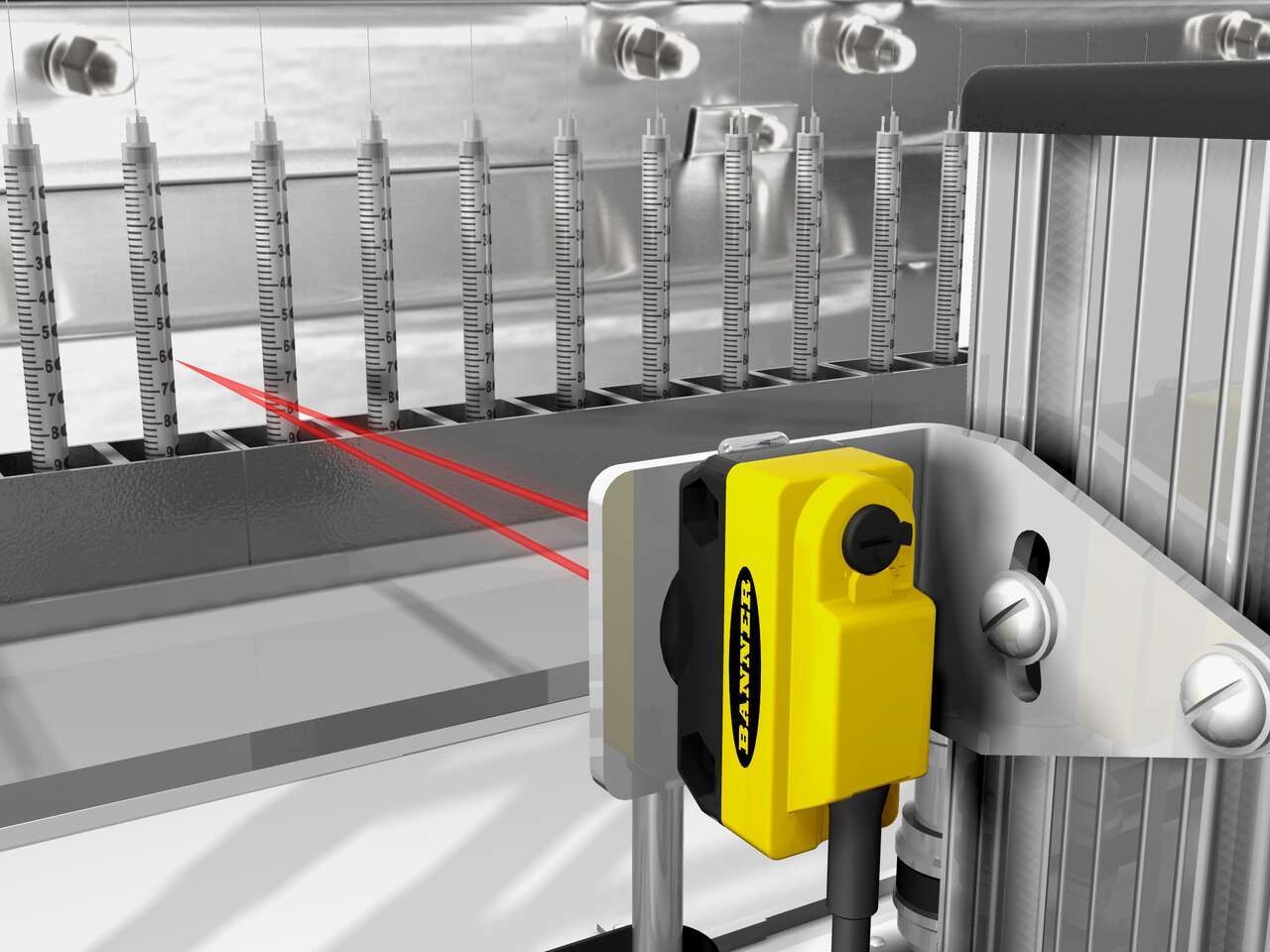

As syringes pass on a conveyor, a WORLD-BEAM QS18 with background suppression detects the individual barrels, passing the information to a counting device.

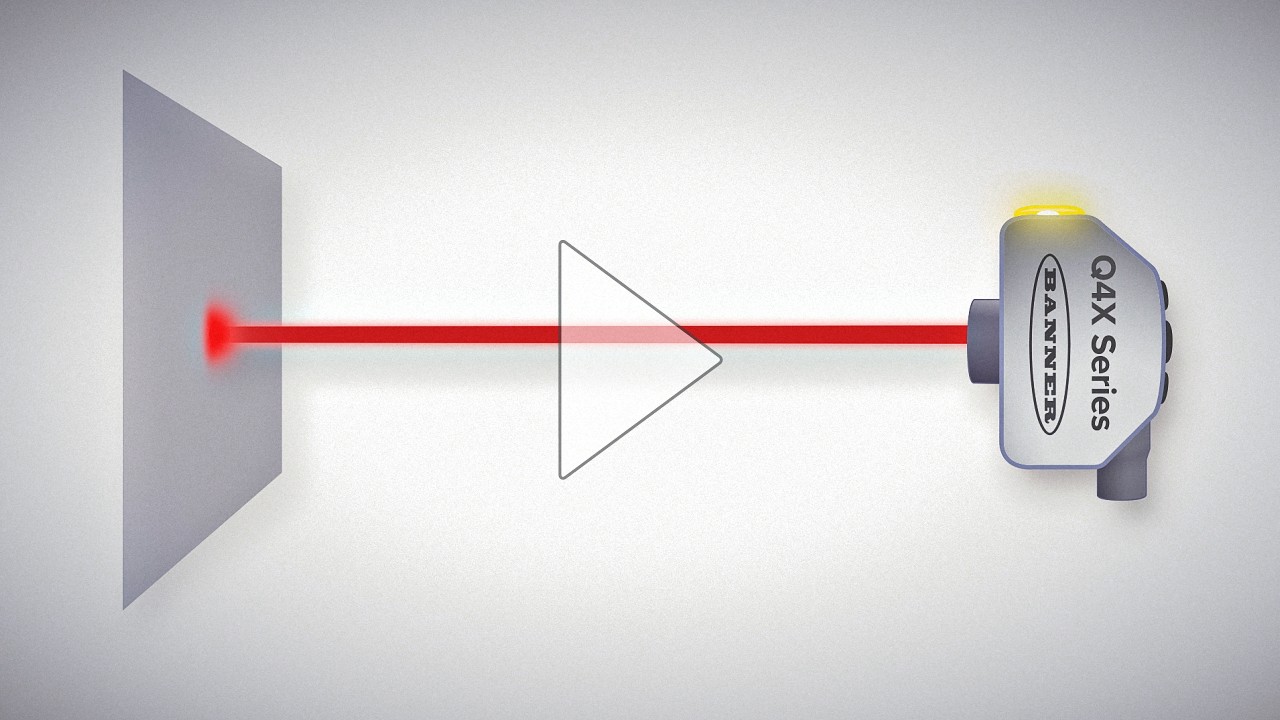

Detecting clear and reflective objects are some of the most challenging sensor applications. Light can burn through a target or be reflected away erratically, making accurate detection difficult.

At Banner Engineering, we're committed to delivering the best shopping experience possible. We noticed that you didn't finish checking out, and we're here to listen if you encountered any obstacles during checkout. Let us know how we could have made your shopping experience even better.

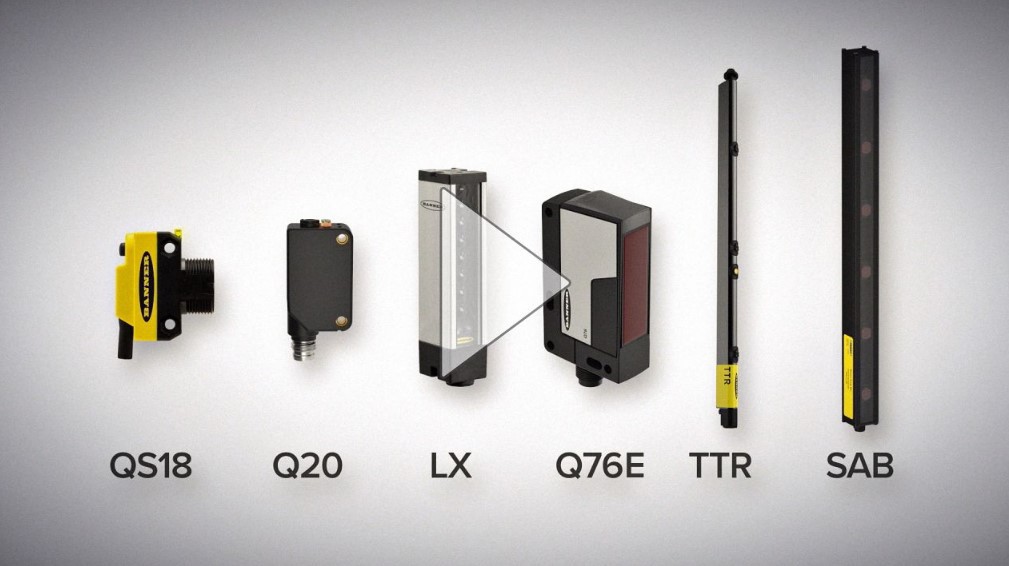

The QS18 Clear Object Sensor is designed for clear object detection in plastic or glass containers.

The QS18 Expert Sensor offers advanced sensing with single push-button programming and several sensing modes and configuration options.

Models with IO-Link communication for simplified wiring, installation, preventative maintenance, and sensor backup.

The QS18 Adjustable-Field Sensor is ideal for background and foreground suppression. The sensor is available in long-range models for sensing up to 300 mm.

The QS18 Laser Sensor has a narrow visible beam spot for easy alignment and small object detection.

The QS18 Universal Voltage Sensor operates on ac or dc voltage and has several sensing models available, making it an ideal sensor for many manufacturing environments.

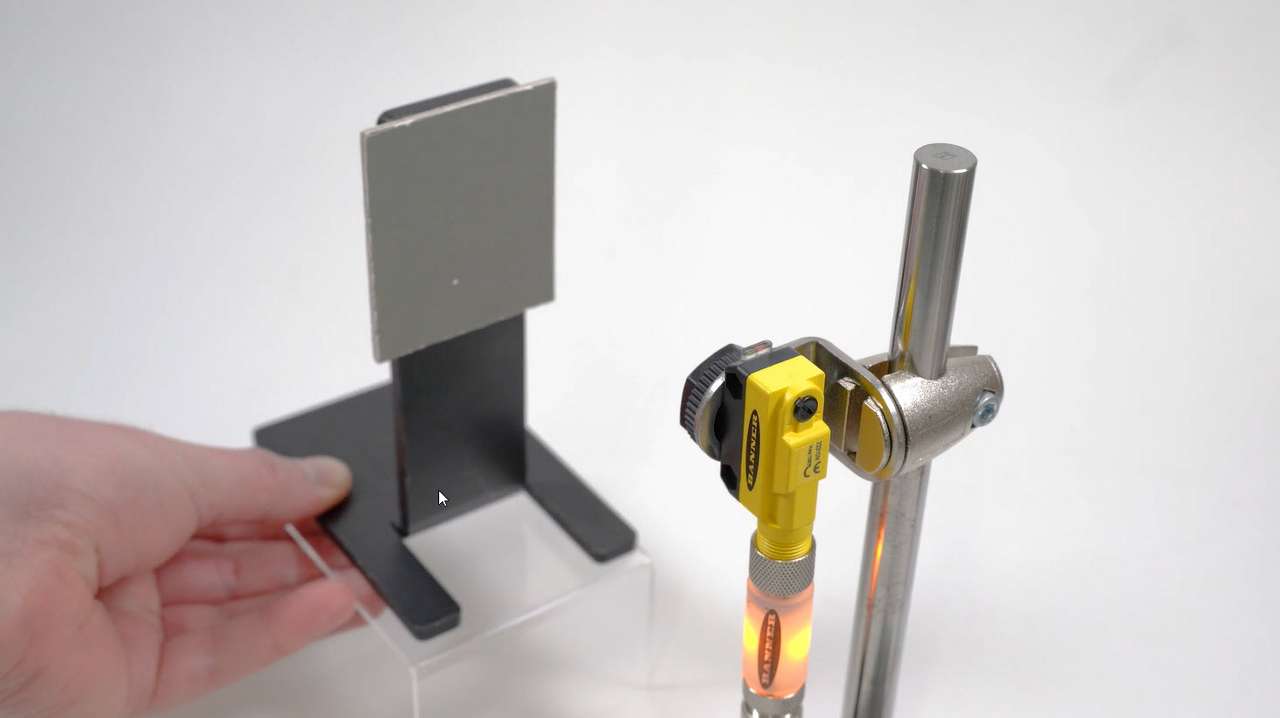

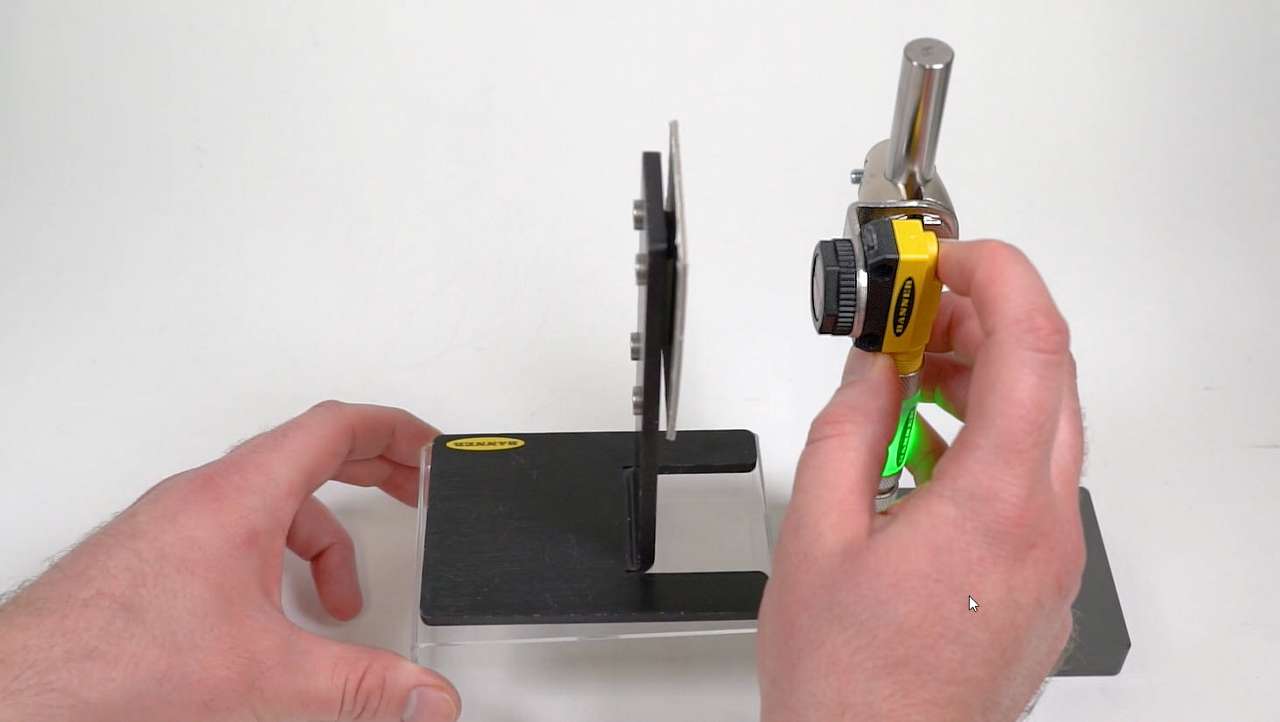

This video covers using a potentiometer to set the sensitivity on a QS18 All-Purpose Photoelectric Sensor from Banner Engineering.

This video covers the light set and dark set modes for the QS18 Expert Photoelectric Sensors from Banner Engineering.

This video covers the window set mode for the QS18 Expert Photoelectric Sensors from Banner Engineering.

This video covers the dynamic teach mode for the QS18 Expert Photoelectric Sensors from Banner Engineering.

This video guides you through the key features of our sensors and helps determine which sensor within our photoelectric portfolio is best for a specific application.

Learn how to pair the best sensor for each leading edge detection application.

Solve more applications, save inventory costs, and help prevent unplanned downtime with Banner's smart sensor solutions.

Expert Coaxial Clear Object Detection Sensor -Reliably detects clear, translucent, or opaque objects -Coaxial optics enable reliable detection of targets to the face of the sensor with no dead zone -Simple single push to teach setup -0–3 m range

Have a question about this product series? Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.