-

Industries

-

Packaging

Packaging

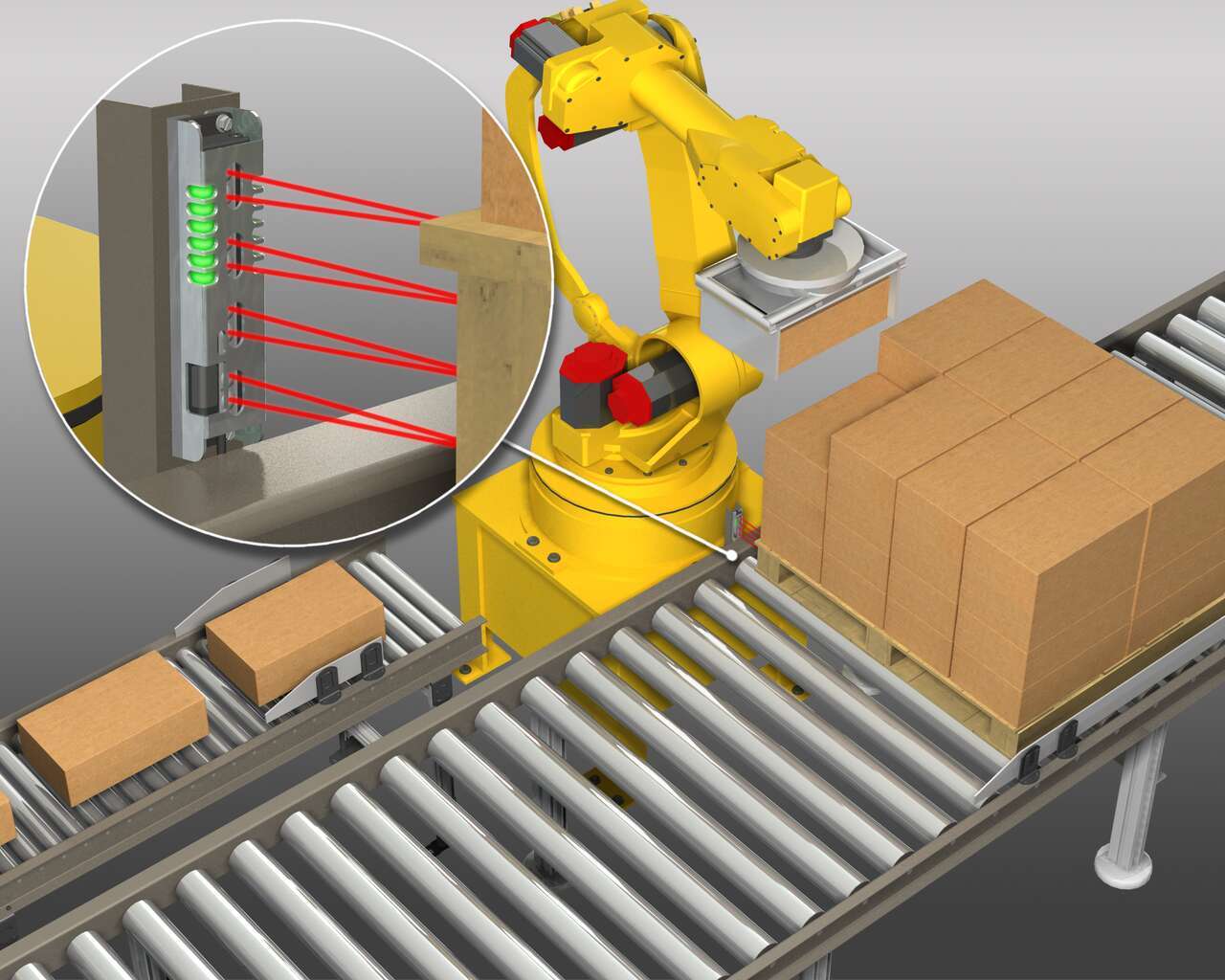

Enhance Packaging Line Efficiency and Safeguard Equipment

Packing, sorting, and palletizing rely on automation to minimize errors and maximize ROI. With the increasing diversity in packing sizes, shapes, colors, and materials, Banner solutions help minimize breakdowns, efficiently and accurately track products through the line, and ensure strict quality control.

The comprehensive selection of sensors, barcode readers, and safety products from Banner is helping companies optimize output and safeguard their lines.

Start with Banner

From primary and secondary packaging to end of line, companies worldwide are using Banner solutions to accelerate production and logistics. Whether adding sensors to existing equipment to enhance capabilities or setting up a completely new line, Banner delivers high performance, reliability, and value.

We are experts in automation technologies, offering a comprehensive catalog of more than 10,000 products, including sensors and measuring devices; lighting, indicators, and displays; connectivity technology; condition monitoring solutions; machine safety products; industrial wireless systems; remote I/O, barcode scanners, and machine vision. By listening to customers and engineering solutions that remove production constraints, Banner is helping them drive efficiencies, improve output and system accuracy, and reduce errors and expenses.

Packaging Industry

Packaging Successes

-

Pallet Detection for Conveyance Equipment

-

Combined Inspections Used to Meet Quality Standards

-

Detecting Various Registration Marks

-

Simplifying Safety Feature Management

-

Accurate Label Inspection

-

Preventing Shipping Errors at a Large Distribution Center

-

Shrink Sleeve Labeling at High Speeds

-

Improved Efficiency and Safety on Packaging Automation System

-

Q5X Series High Power, Multi-Purpose Photoelectric Sensor

Q5X Series High Power, Multi-Purpose Photoelectric SensorA powerful, problem-solving sensor in a cost-effective device with industry-standard rectangular housing. With a range from 50 mm to 5 m, the Q5X provides reliable detection of the most challenging targets.