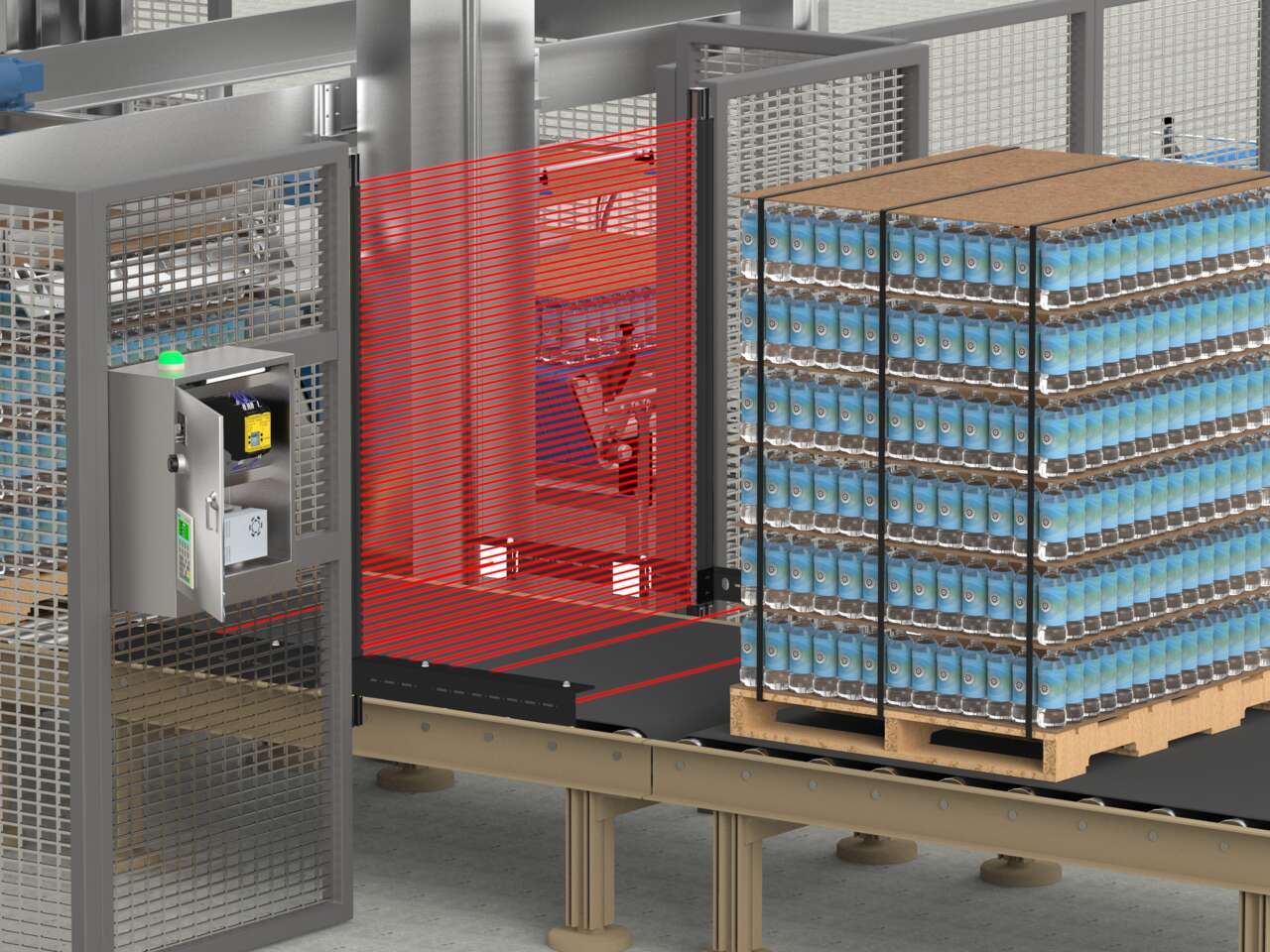

Primary Beverage Packaging

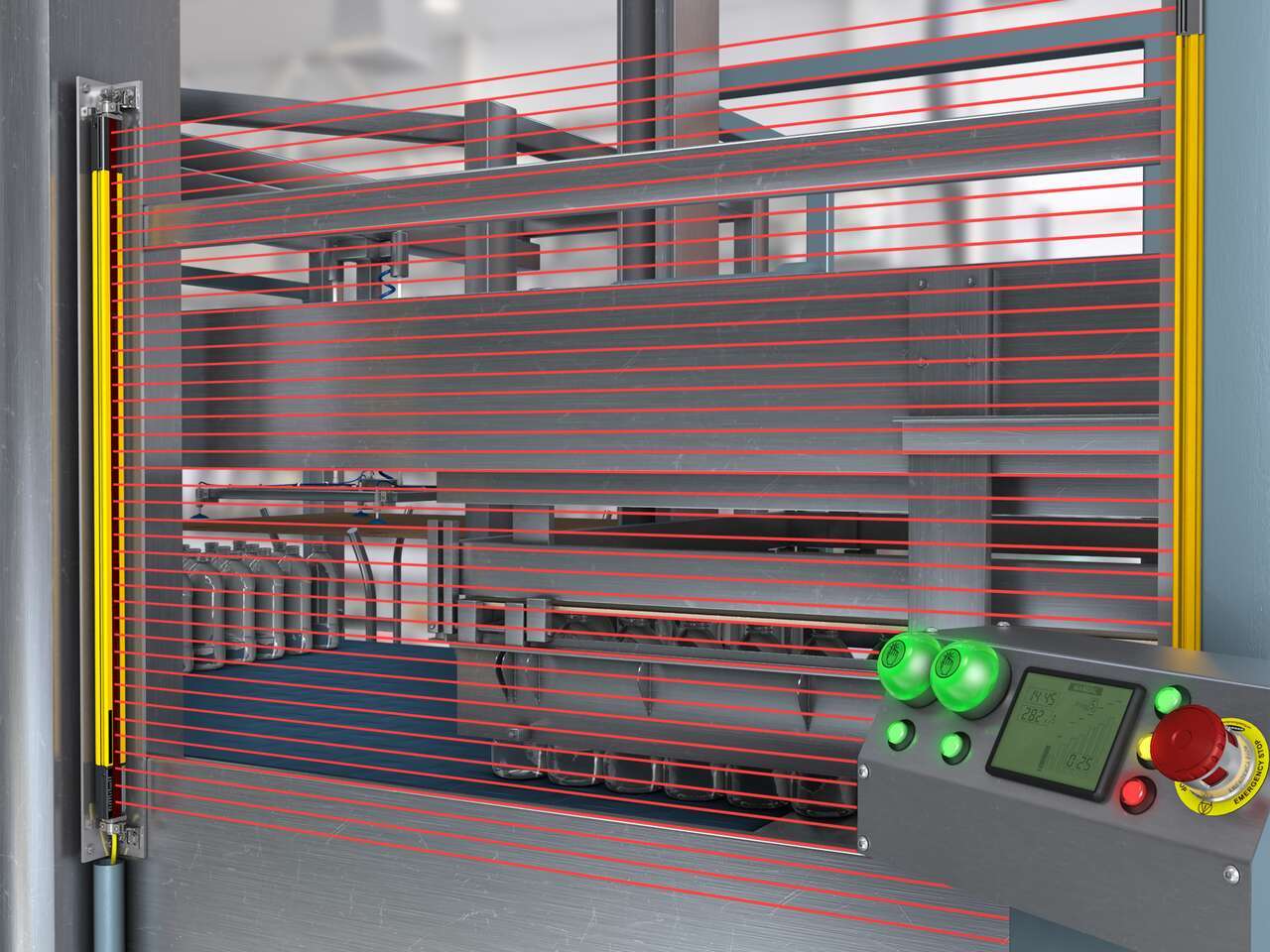

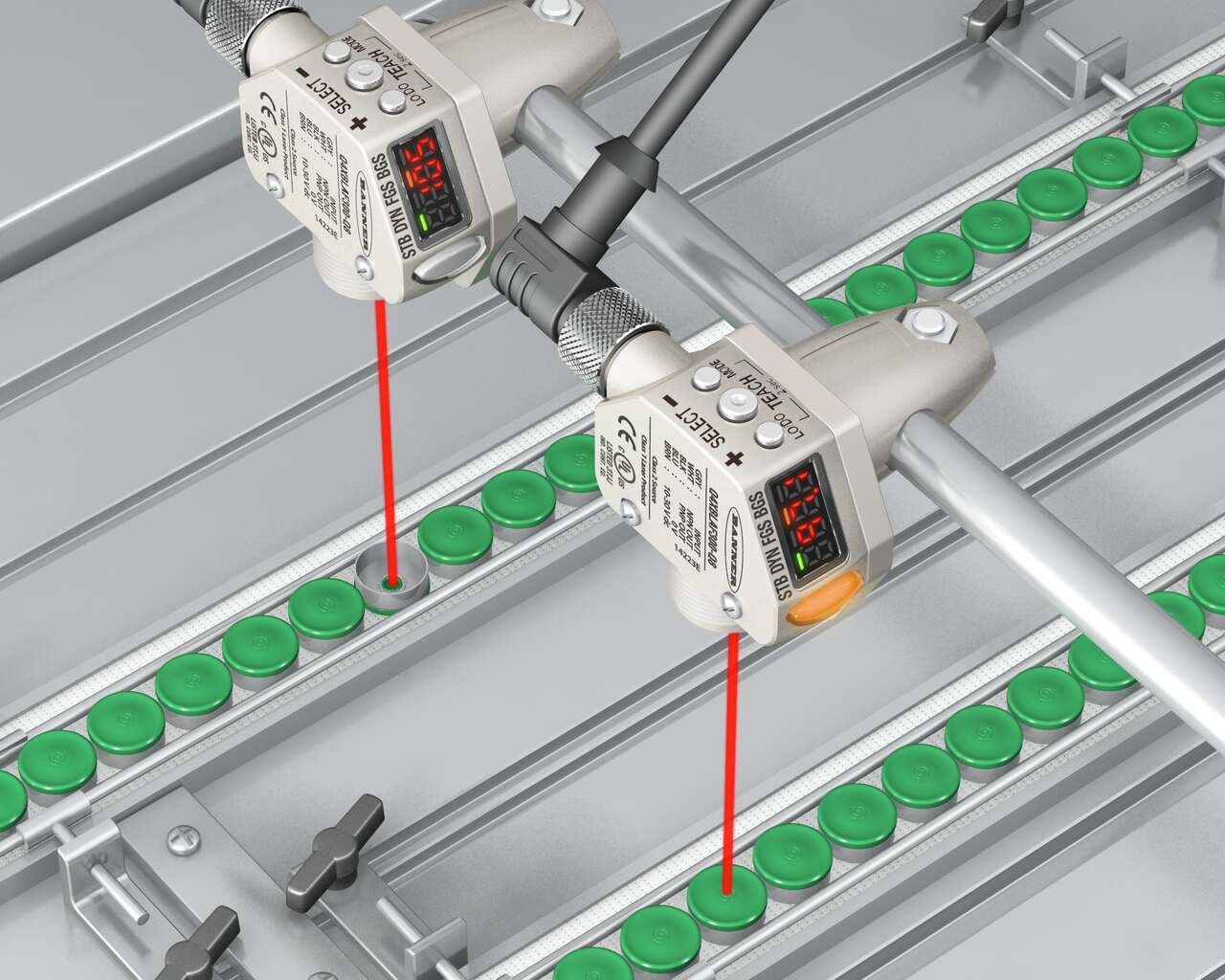

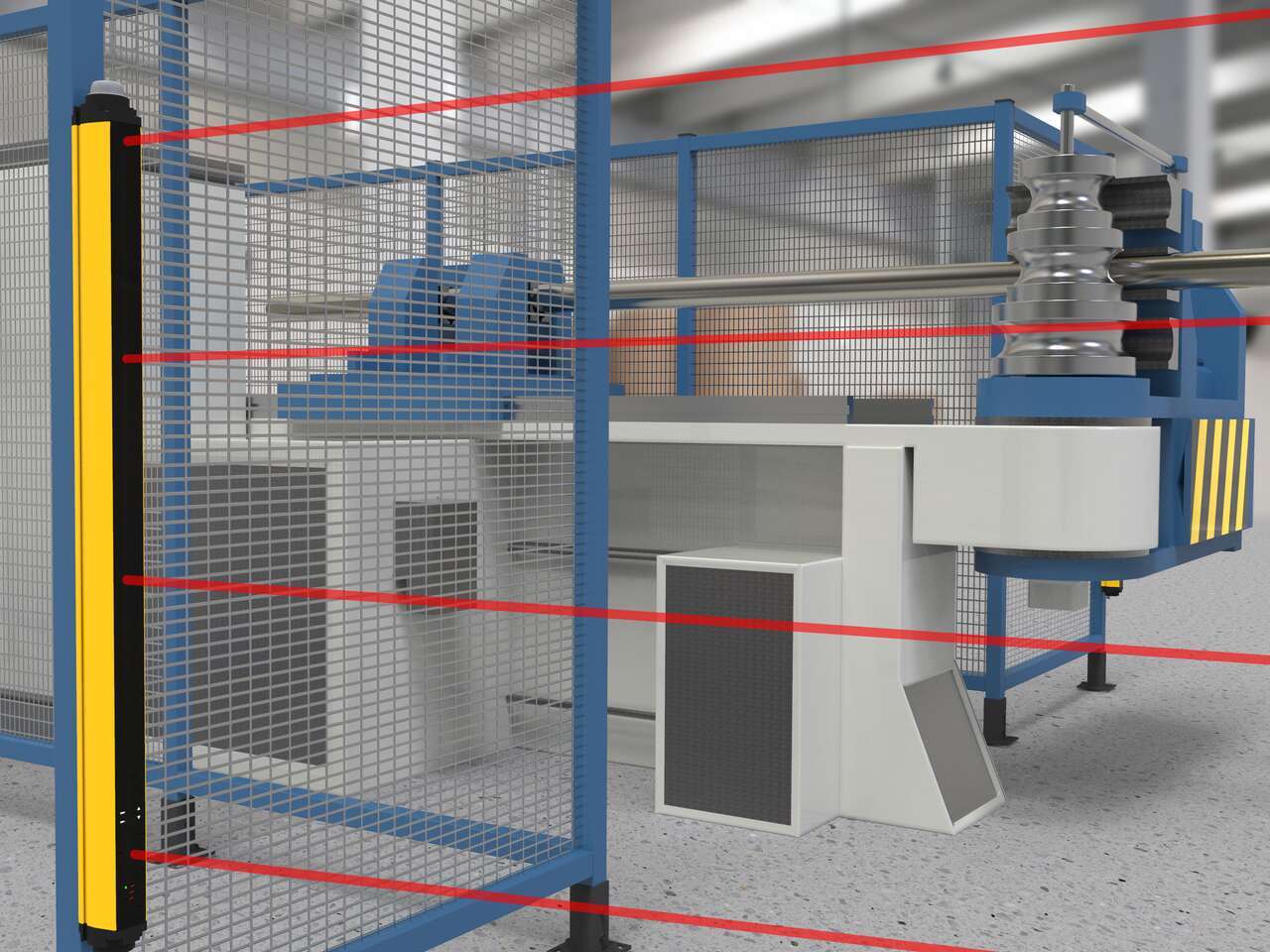

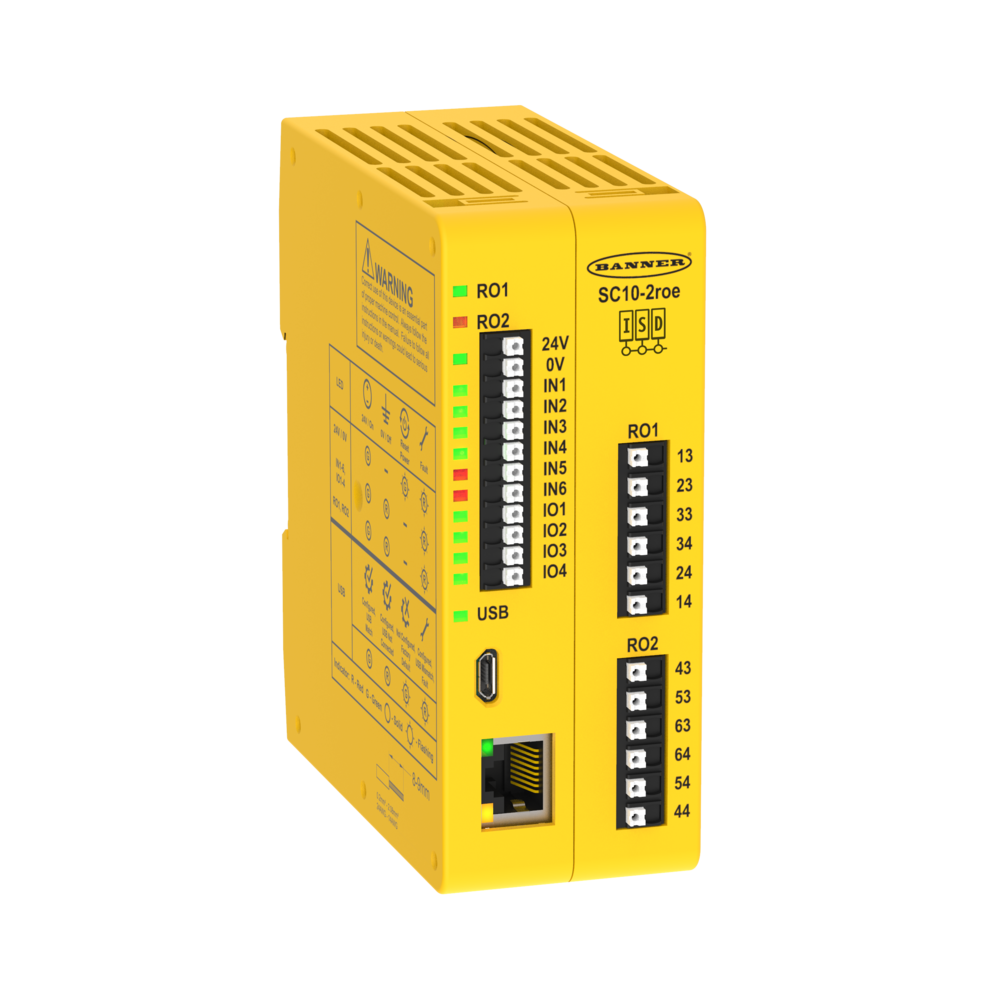

From IP69K rated products that resist high-pressure, high-temperature washdown to heavy-duty safety equipment that protects personnel from accident or injury, products and solutions from Banner Engineering help beverage producers meet the many challenges found throughout beverage filling.