Illumination for Visual Inspections

Improve Quality and Efficiency

Defects and errors in parts and components can negatively impact downstream processes, production efficiency, and product quality.

Visual inspection of parts and components can help manufacturers identify potential issues early on in the manufacturing process, minimizing lost product and production time.

Proper lighting makes it easier for workers to perform visual inspections with fewer errors by providing uniform illumination, reducing eye strain, and improving contrast.

Improper Lighting Can Lead to Mistakes

If compared to fluorescent lights, which tend to flicker from changes in intensity, the LED lighting is more ergonomic for an operator. The inconsistent output of fluorescent light, plus the emission of UV and heat, can make it challenging to perform inspection tasks accurately. Furthermore, the eye strain and operator fatigue caused by poor lighting can reduce both the speed and effectiveness of visual inspections.

In contrast, bright LED task lights provide stable, durable, and uniform lighting for quality inspection, which helps ensure accuracy and increase efficiency. Ultra-bright LED lights from Banner Engineering will never require a bulb or ballast replacement over their more than 50,000 hours of operational life to provide years of maintenance-free illumination.

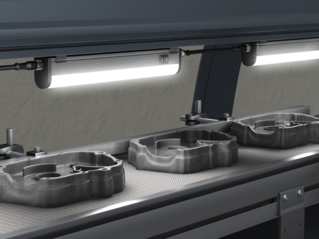

Extremely Bright Light with no Hotspots

- During the quality inspection of cars and automotive parts, bright, also, uniform light is essential to inspect parts properly.

- The most important part of lighting up an automotive environment for inspection purposes is to find a light source that provides consistent, extremely bright light.

- The energy-efficient WLB92 is easy to install and gives a consistent, bright light with no hotspots and minimal glare to inspect automotive parts.

- Increased lighting can improve worker productivity and reduce eye strain, resulting in more reliable quality inspections.

Years of Reliable Operation

- Fluorescent lights often require multiple bulb replacements each year, as well as periodic ballast replacements. Fluorescent lights can also lose intensity and become discolored, making inspections more difficult.

- In contrast, LEDs provide intense, daylight white illumination that is distributed evenly across the inspection area.

- LED light bars, like the WLB32 from Banner, provide years of maintenance-free operation, with no bulb or ballast changes required throughout the lifespan of the device.

Choose the Right Light for Your Application

- In some cases, overhead white light does not provide sufficient contrast for surface inspections of objects.

- When inspecting metal or plastic surfaces, imperfections such as fingerprints, dirt, or damaged areas can easily be overlooked.

- Green wavelengths are easiest for the human eye to see and adding green lights into the inspection area helps maximize the effectiveness of metal, glass, and plastic inspections.

- Some oils also react to bright green lights, making oil spots more visible. This is especially important in the automotive industry where oil residue can cause fisheye imperfections, small circular spots that appear on contaminated surfaces.

Our Brightest LED Strip Light

The WLB92 is an ultra-bright LED fixture with an even light output which provides bright task lighting, enabling increased productivity.

- Increase worker productivity and ergonomics with bright, high-quality, uniform light

- Durable light stands up in your environment with a rugged metal housing and shatterproof light cover

- No maintenance time or cost with long-life, energy-efficient LEDs

- Flexibility to place light where needed with ac and dc models

- Easy installation with a variety of mounting options: surface, swivel, snap and hanging brackets

- Available in white, warm white, blue, red, yellow and green

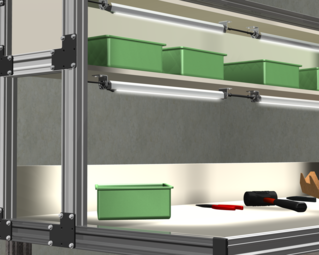

Adjustable LED Work Light

Banner’s WLB32 is a bright LED fixture that features an even light output to eliminate glare.

- Energy efficient for overall cost savings

- High/Low/Off switch allows users to customize light levels

- Available as cascadable models for a continuous length of lighting, with a minimum of wiring

- Metal housing, shatterproof window

- Easy installation with snap clips, or a choice of magnetic or angle brackets

- Available in AC or DC models

- Available in 285 mm, 570 mm, 850 mm or 1130 mm

- Motion detection models are ideal for locations that cannot use a physical switch or where the placement of the switch is not useful

- Models featuring an eye shield window block direct line of sight to the domed window to increase eye comfort

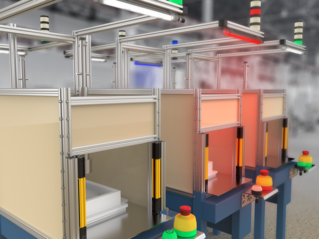

WLS27 Series

Shatterproof Multicolor LED Strip Light

Heavy-duty LED strip lights are fully enclosed in a shatterproof copolyester shell to provide brilliant illumination for a broad range of applications in challenging environments.

- Cylindrical shape design, ideal for laminar airflow applications

- Rugged, water-resistant IP66, IP67 and IP69K construction

- Chemically resistant copolyester housing

- Available in eight lengths from 145 mm to 1130 mm

- Daisy chain power to multiple lights

- Capability to dim lights using the wiring pinout (Hi/Lo/Off)

- Optional snap clips for easy installation and repositioning

- Automatic temperature protection built into the unit. Above 50 °C, the light dims to manage heat and protect product lifetime

- Three- and five-color models with EZ-STATUS® combine illumination and indication in one robust light fixture

- Now available with heavy diffuse windows for reduced intensity and a more uniform light distribution