-

Industries

-

Electronics

Electronics

Ensure Productivity with Reliable Performance

Protecting personnel from danger while still maintaining an efficient workflow. Accurately identifying objects of various shapes, colors, and textures. Reliably detecting transparent and translucent objects. Facilities are sharing their goals with Banner to create safe, functional, and affordable work zones that maximize productivity.

From measurement and inspection to quality control and circuit integration, our compact, cost-effective devices offer intuitive operation and advanced capabilities to address numerous applications.

Start with Banner

The electronics industry is always growing and expanding, which means that our products are constantly adapting to meet the needs of manufacturers. Equipment manufacturers rely on Banner to help them reduce expenses and increase efficiency. The expansive selection of products and expertise from Banner Engineering enables them to implement safeguards and reliably detect objects with ease.

We are experts in automation technologies, offering a comprehensive catalog of more than 10,000 products, including sensors and measuring devices; lighting, indicators, and displays; connectivity technology; condition monitoring solutions; machine safety products; industrial wireless systems; remote I/O, barcode scanners, and machine vision. By listening to customers and engineering solutions that remove production constraints, Banner is helping them drive efficiencies, improve output and system accuracy, and reduce errors and expenses.

Electronics Solutions

-

-

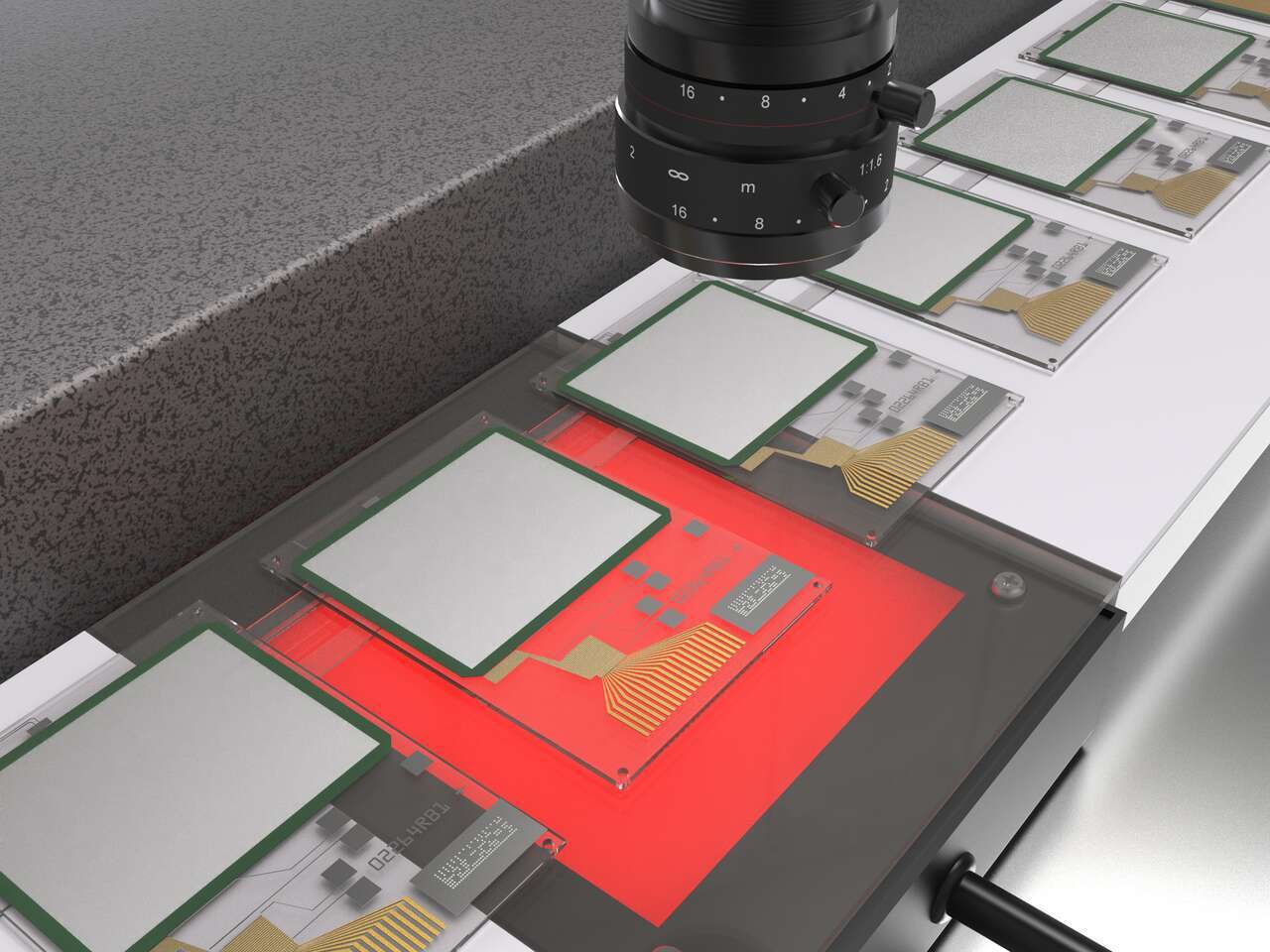

Fine Detail Inspection of Mobile Electronic Devices

-

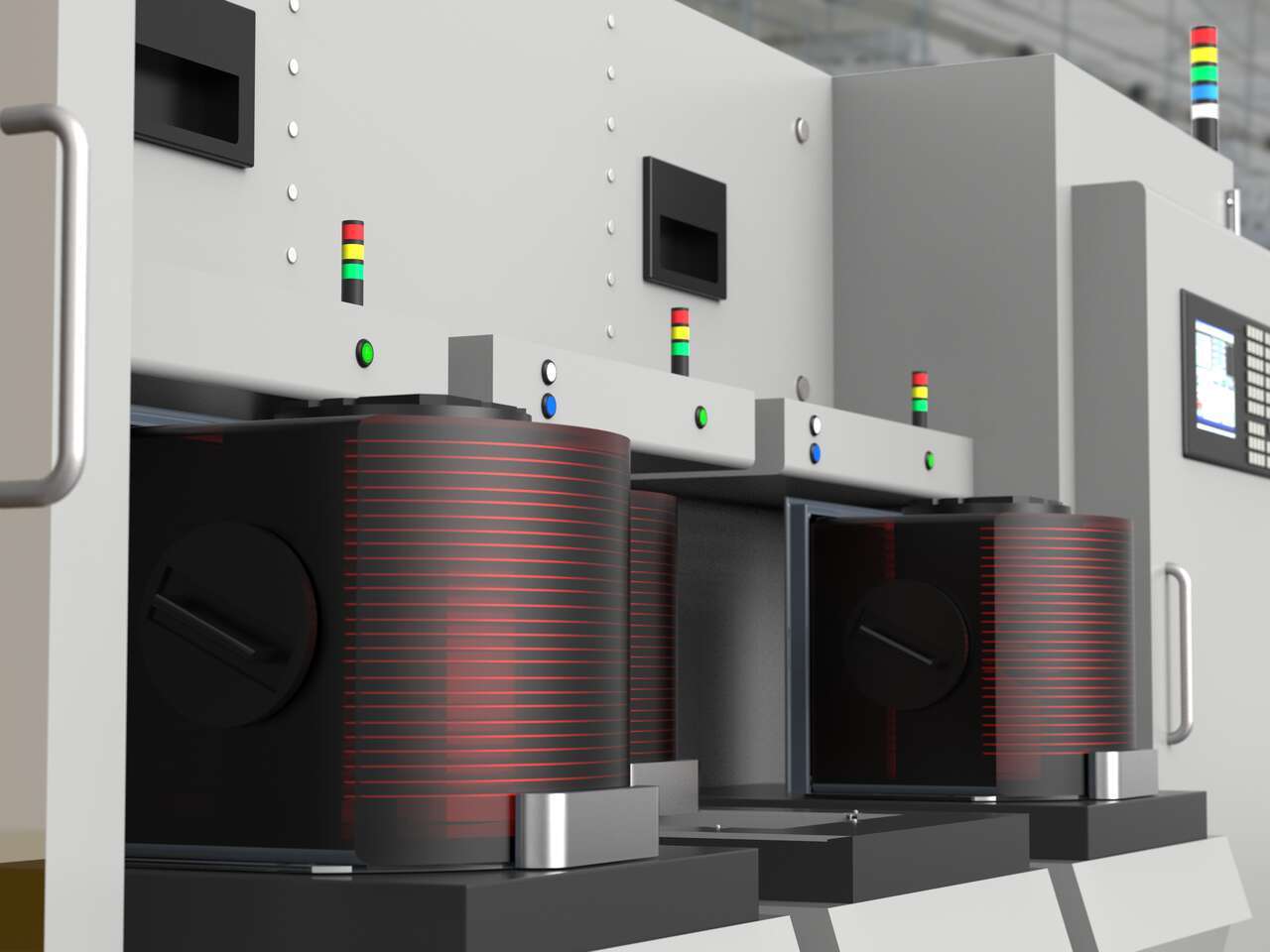

Environmental Monitoring inside a Machine Control Panel

-

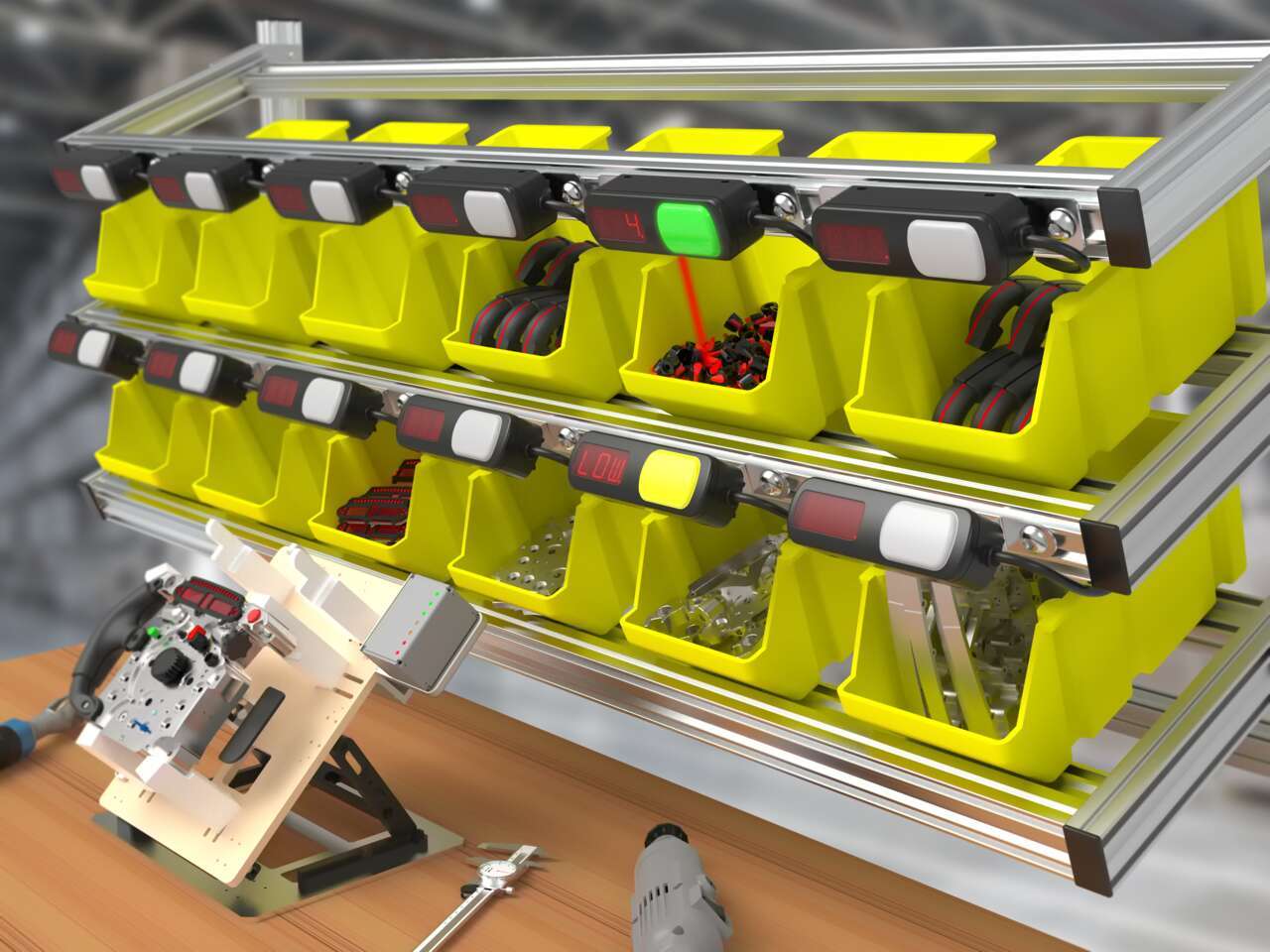

Multiproduct Light-Guided Assembly Station

-

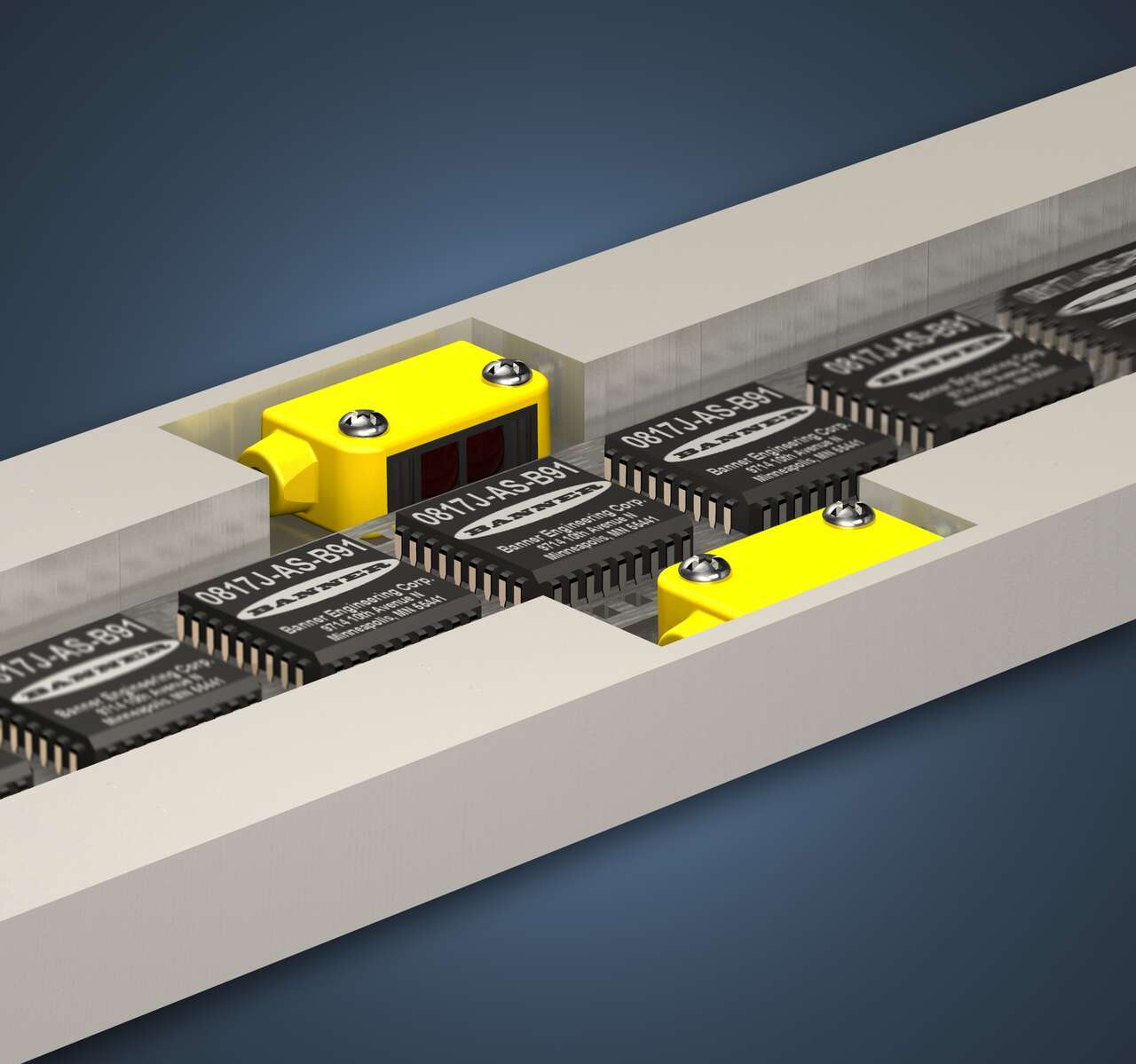

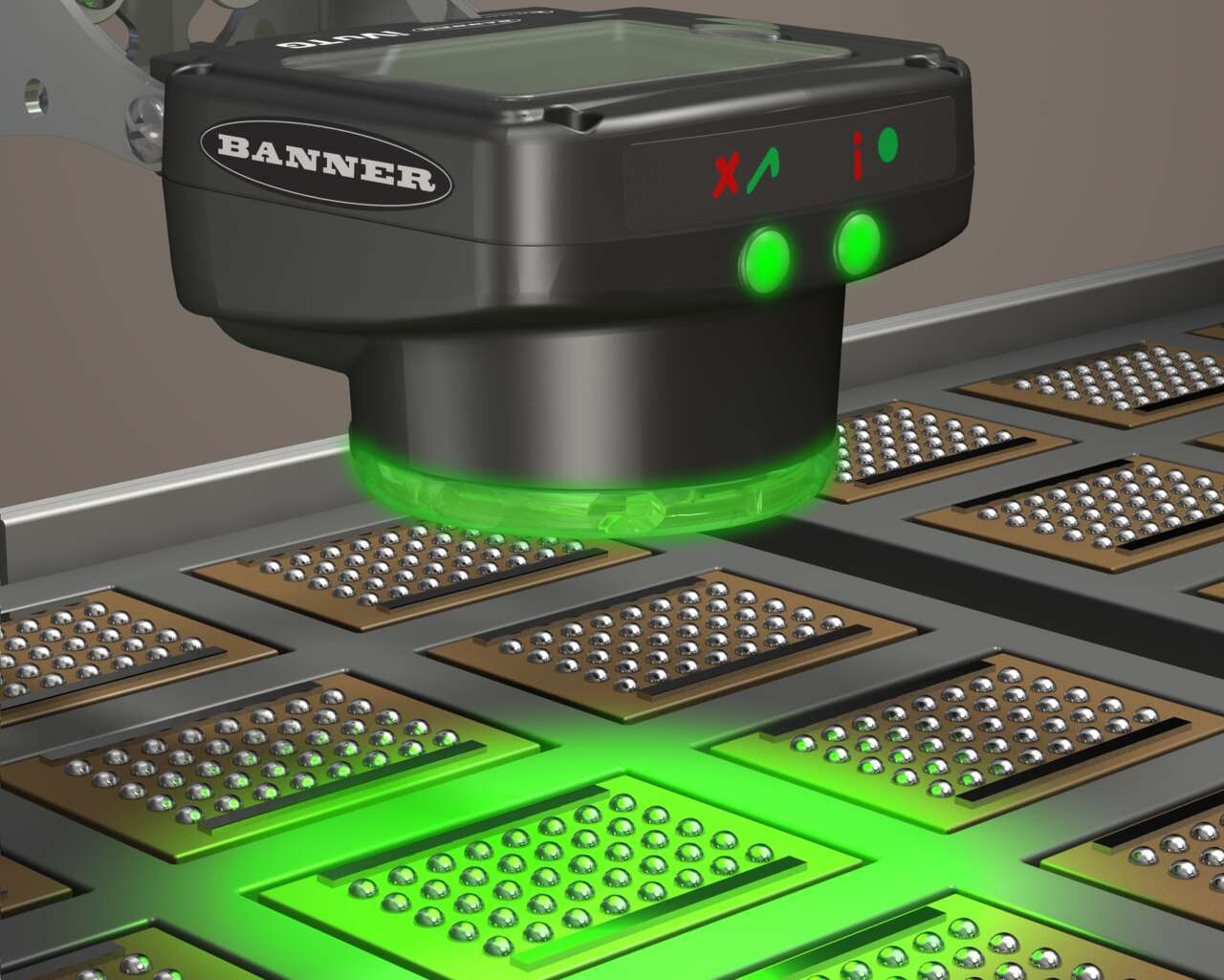

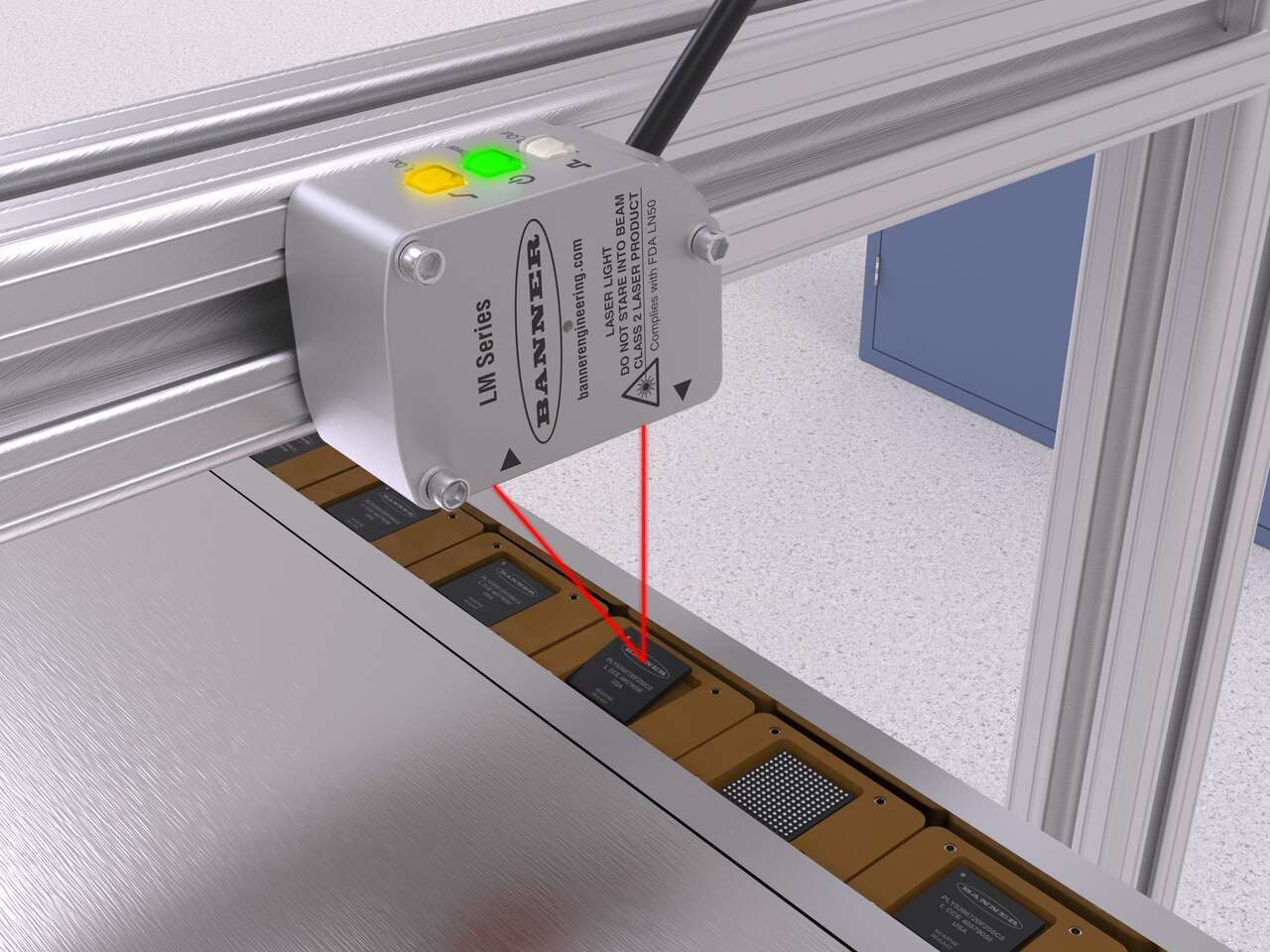

Counting Integrated Circuits

-

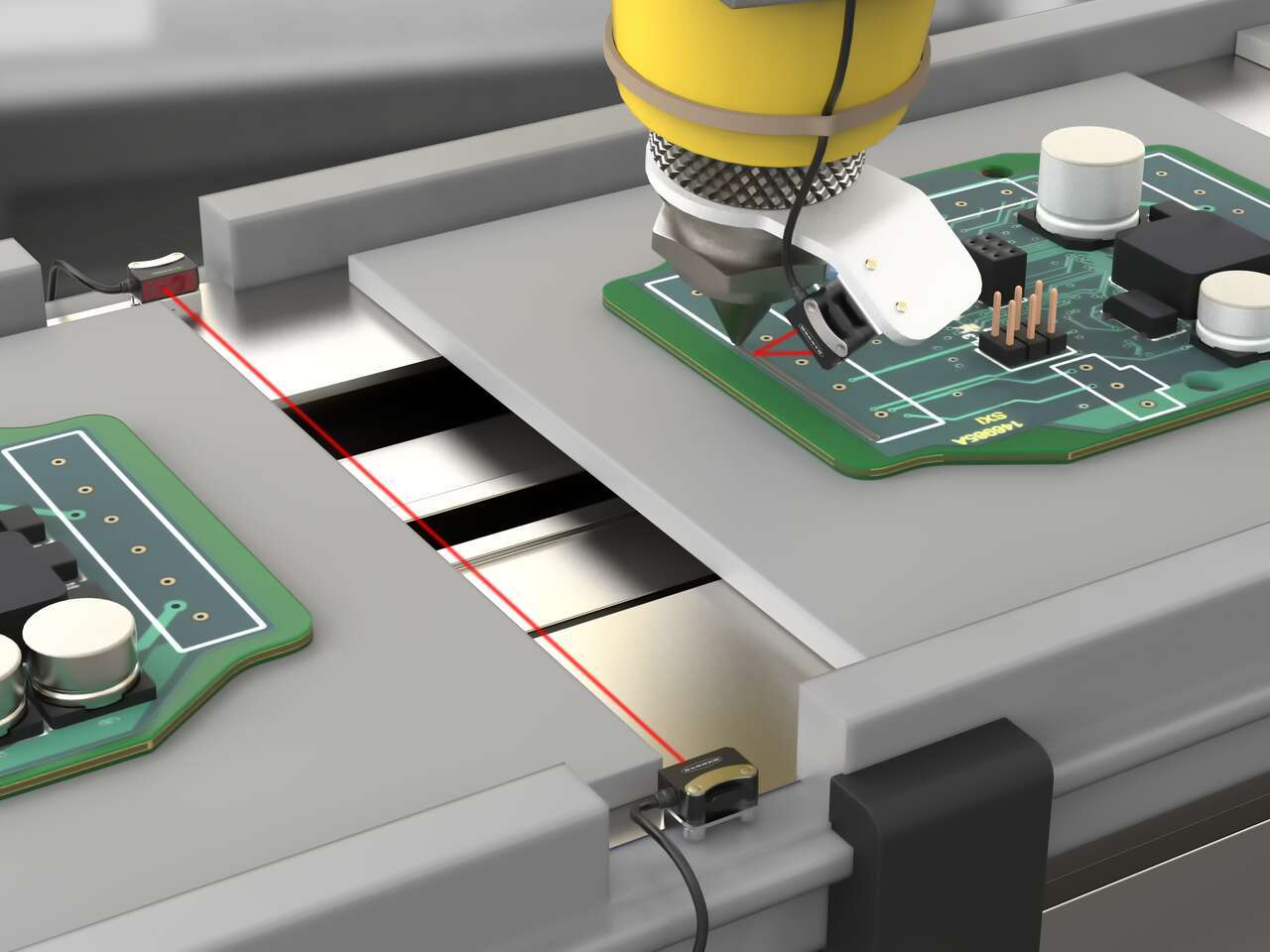

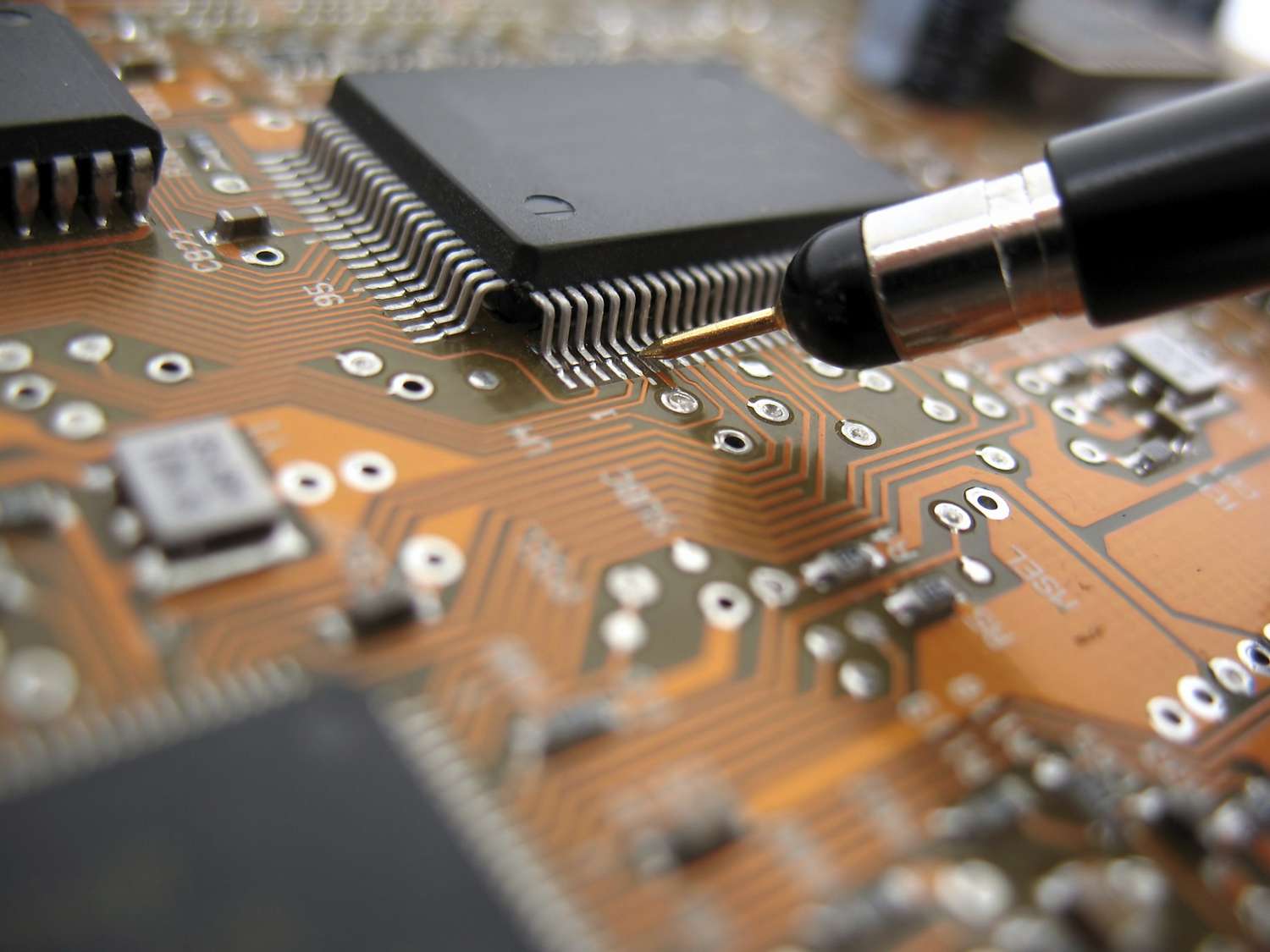

Real-Time Adhesive Detection in PCB Assembly

-

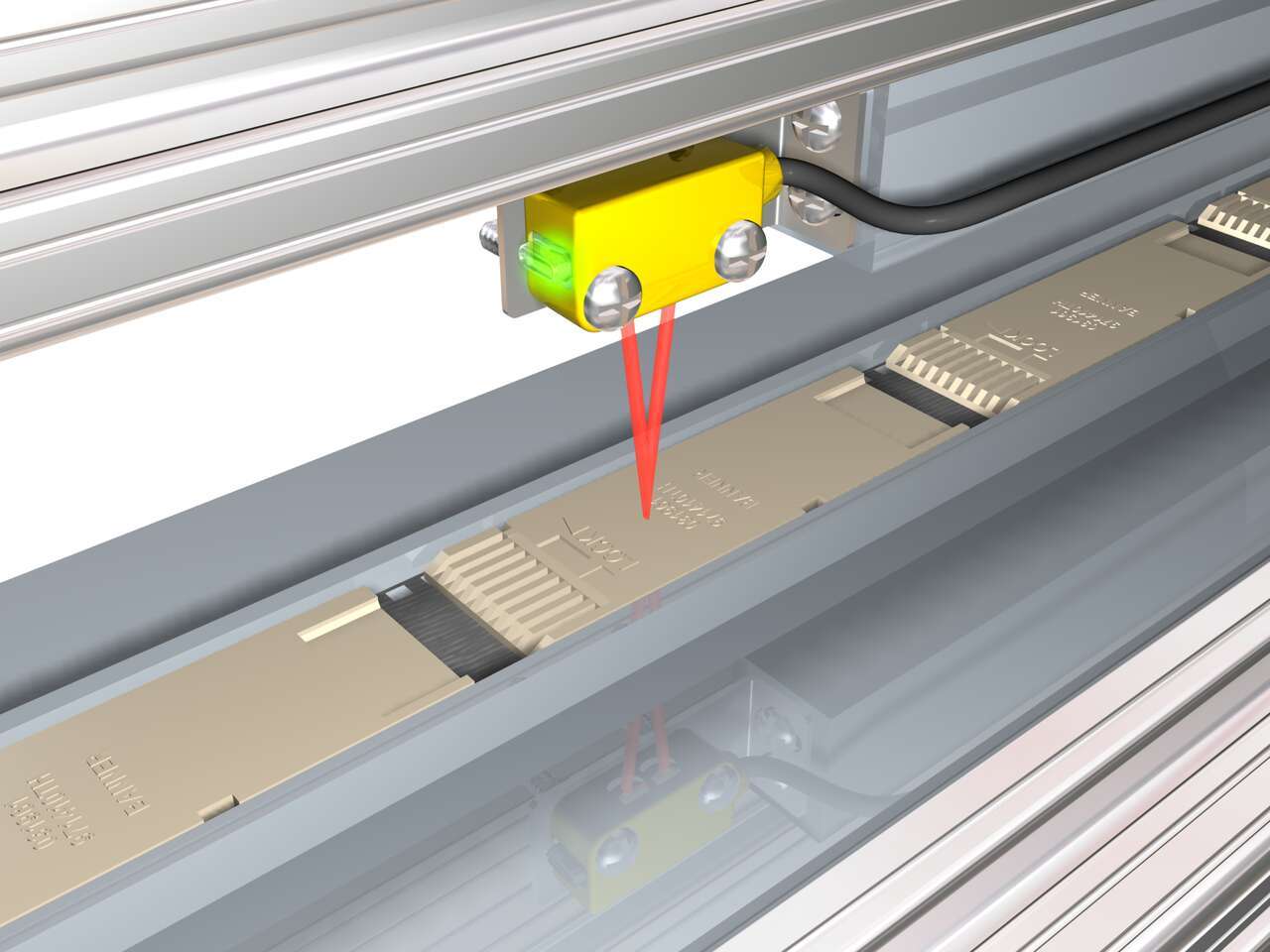

Error-Proofing Loading of IC Chips into Pocket Tape

-

Hard Disk Detection

-

Counting Memory Sticks

-

Verification of Two Barcodes on a Part

-

Industrial Barcode Verification on a Cell Phone Component

-

Easy-to-See Status Indication in Close Proximity to Staff

-

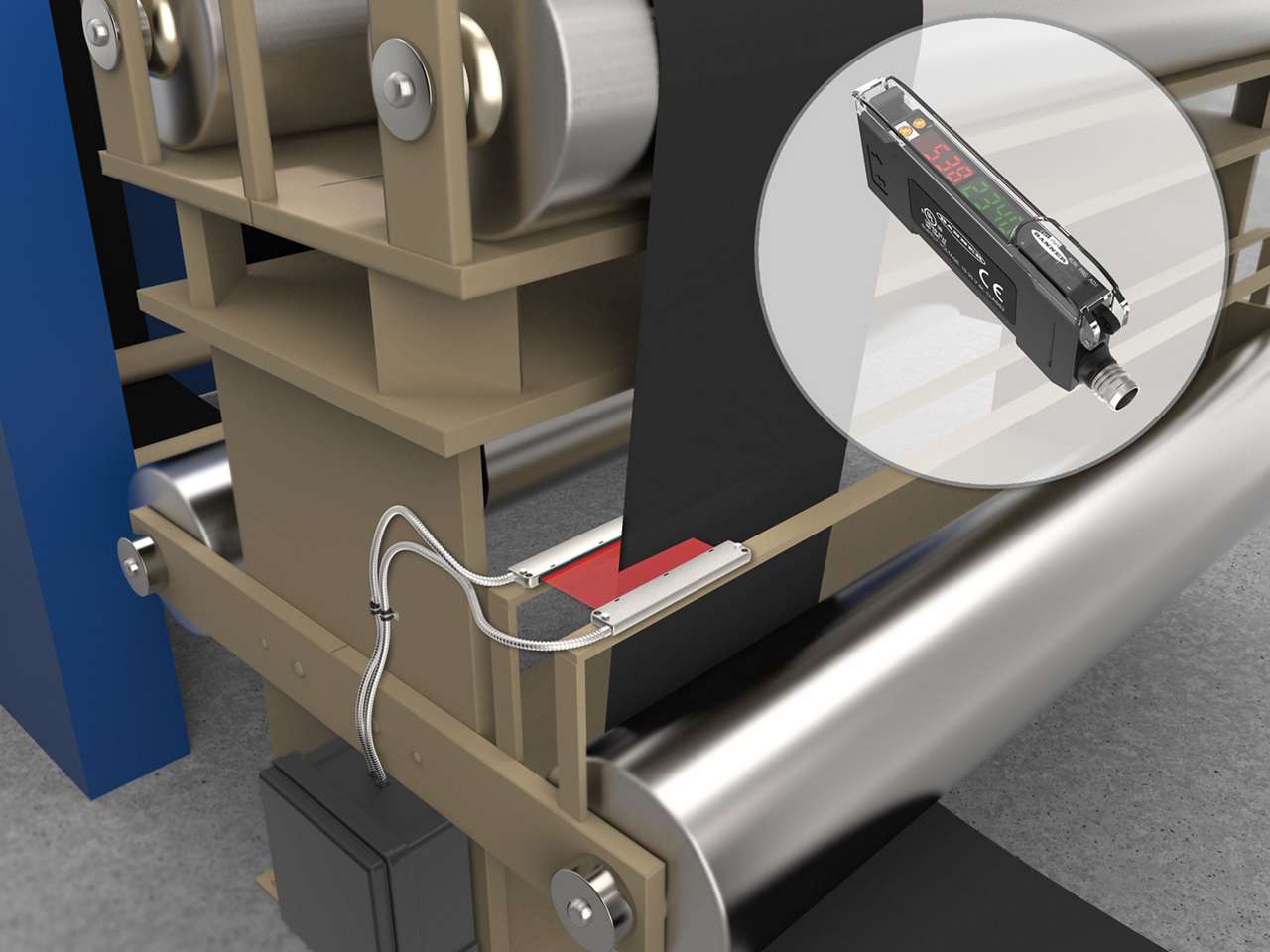

Edge Guiding for Battery Manufacturing

-

Solder Ball Inspection

-

Adhesive Bead Detection

-

Part Flaw Detection

-

Detecting Integrated Circuit Chip Presence and Orientation

-

Electronic Marking Verification

-

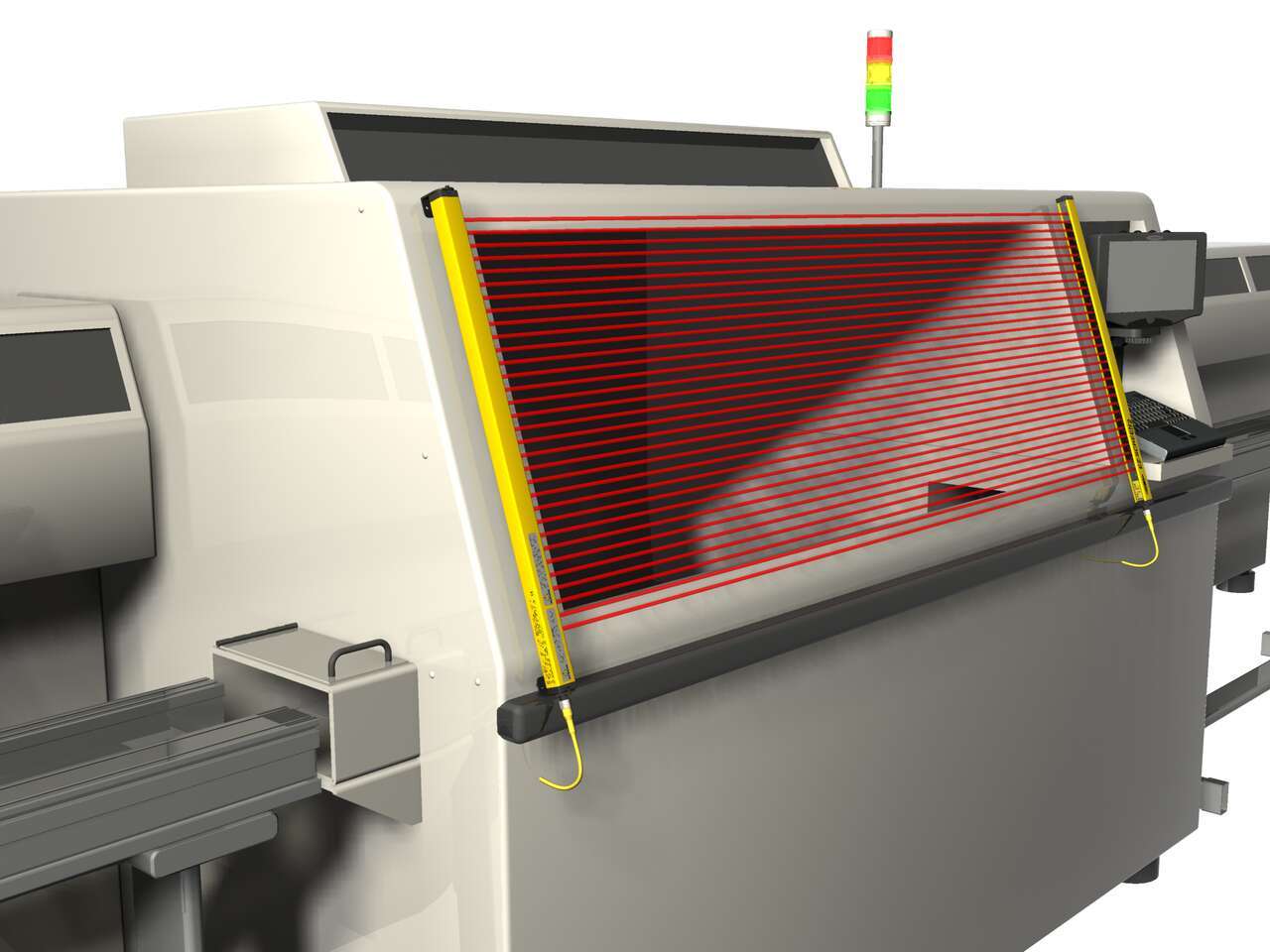

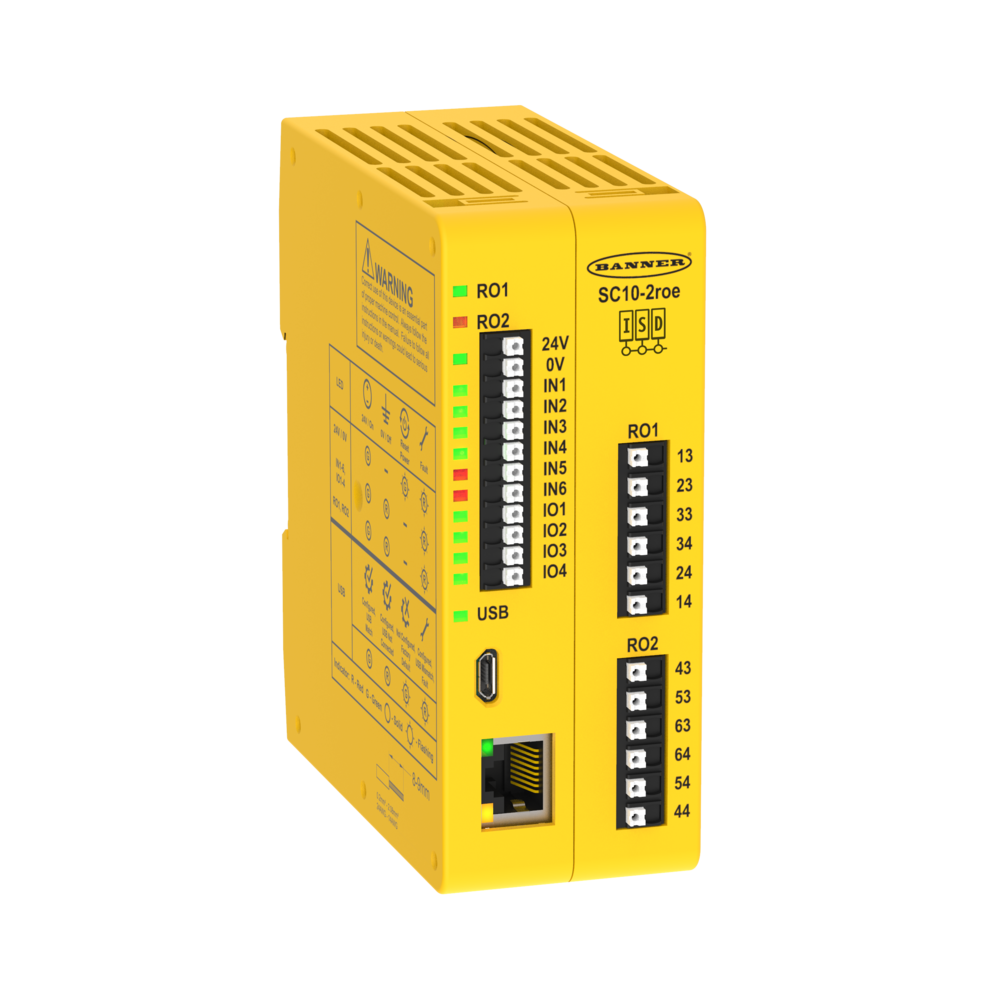

Safety Control on Small Machines

-

Lower-Risk Machine Guarding: Carousel

-

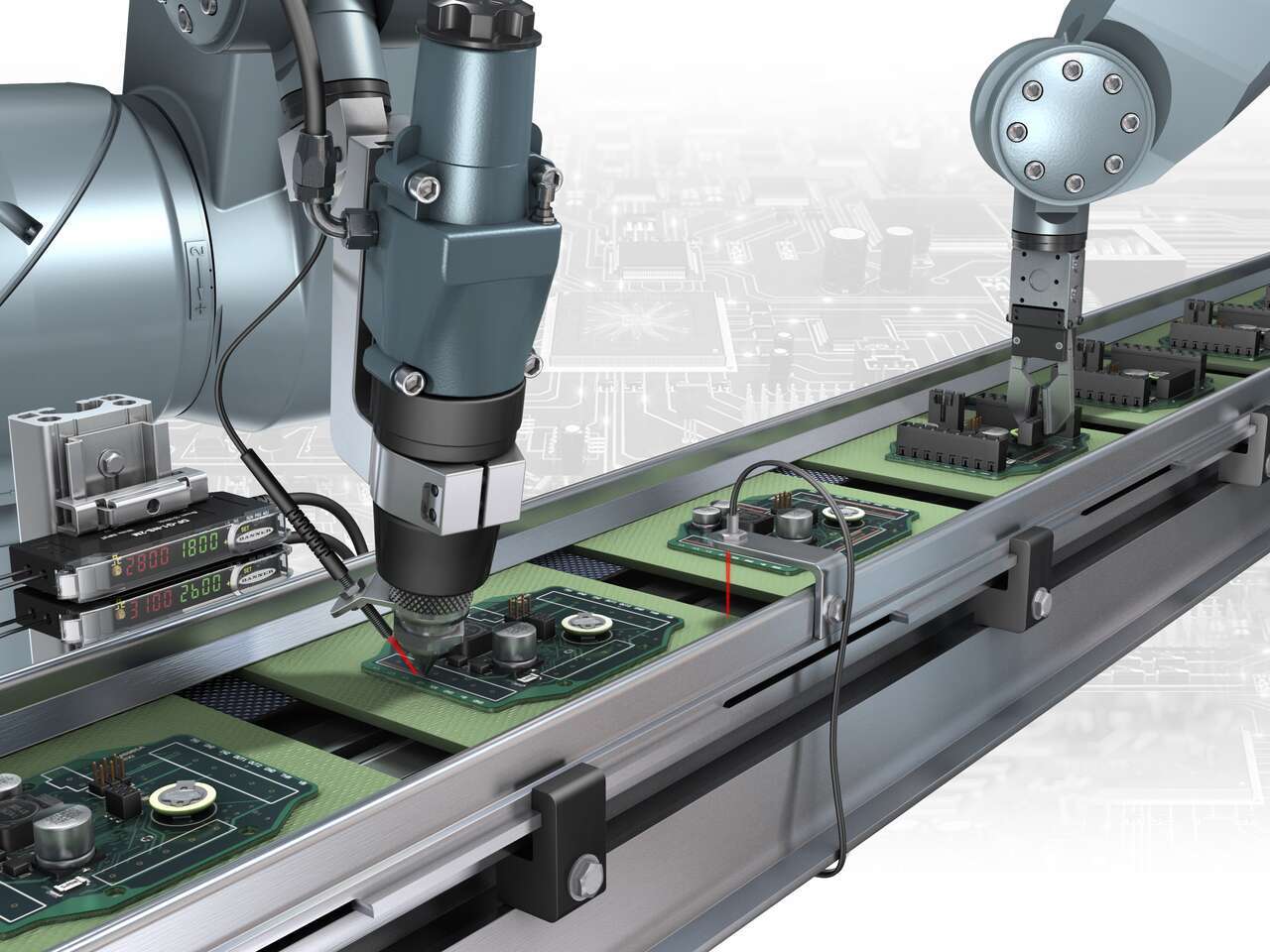

Lower-Risk Machine Guarding: Chip Shooter

Tape Detection

Film can be damaged during the automatic winding process and needs to be removed to prevent further defects. Green or yellow tape is applied to sections of film where a tear or other type of damage has been identified. The DF-G2 fiber optic amplifier, paired with tight bend radius fibers and white LEDs, detects the translucent green and yellow tape so the machine accurately cuts out the damaged sections.

-

Fiber Optic Amplifiers | DF-G3

DF-G3 Series Long Range Fiber Optic AmplifierFiber amplifier with IO-Link capability for detection up to 6 m, precise positioning, and water detection. Output: analog, discrete, dual discrete.

-

Safety Light Curtain Emitters and Receivers | SLC4

SLC4 Series Emitters and ReceiversSLC4 safety light curtains are our shortest, most compact safety light curtains. They are designed to safeguard points of access and operation on smaller production machines and similar equipment.

-

Laser Distance Measurement | Q4X

Detect Clear Objects More Reliably in Harsh EnvironmentsThis smart sensor solves countless problems, has the power and capability of several sensors in one, uses a food-grade housing, and does not require a reflector target.

-

Safety Controllers and Safety Relays | SC10

SC10 Safety Controller / Relay HybridReplaces the functionality of two safety relay modules with one compact, cost-effective device. Supports up to 10 inputs, 4 convertible inputs, and 2 dual channel 6 Amp relay outputs.

Banner Engineering's Electronic Solutions Brochure highlights Industry 4.0 technology and solutions for Lithium Ion battery production, solar panel production, IC chips and printed circuit boards, mobile device production, contract manufacturing (EMS) and clear object detection (COD).