Industrial Wireless

Wireless products from Banner connect remote assets with the people who manage them, enabling real-time monitoring and management of equipment and conditions.

Product Categories

Monitoring Solutions

Trends

-

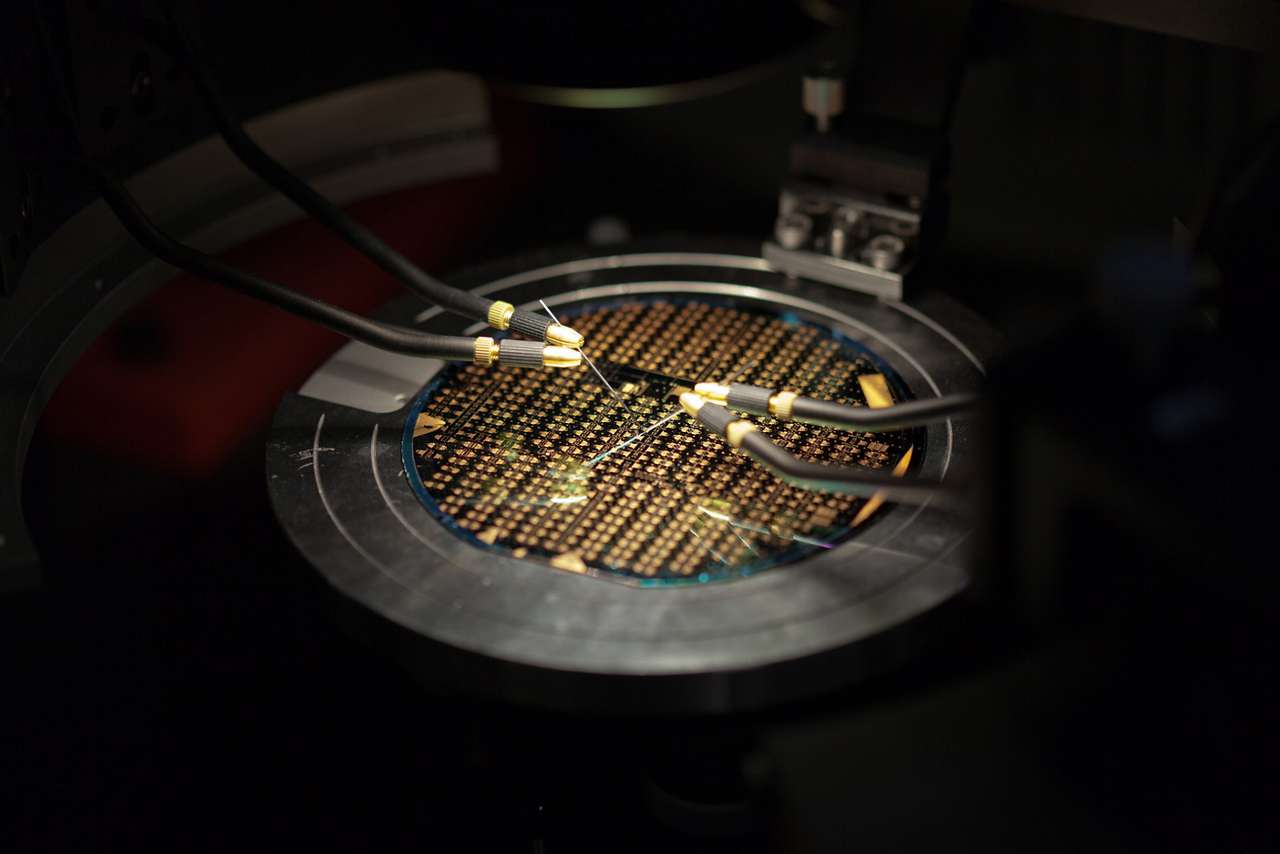

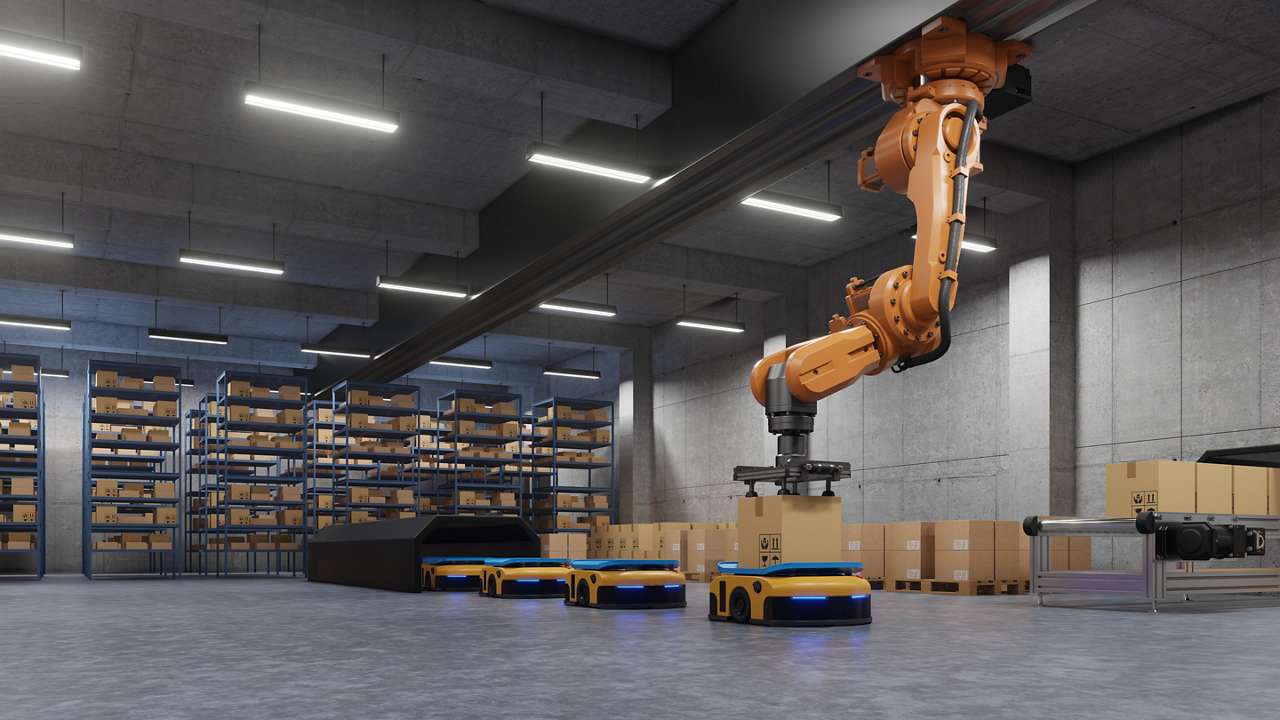

IIOT Innovations for the Data-Driven Factory

The Industrial Internet of Things (IIoT) describes the technologies that connect industrial field devices, such as sensors, to the cloud.

-

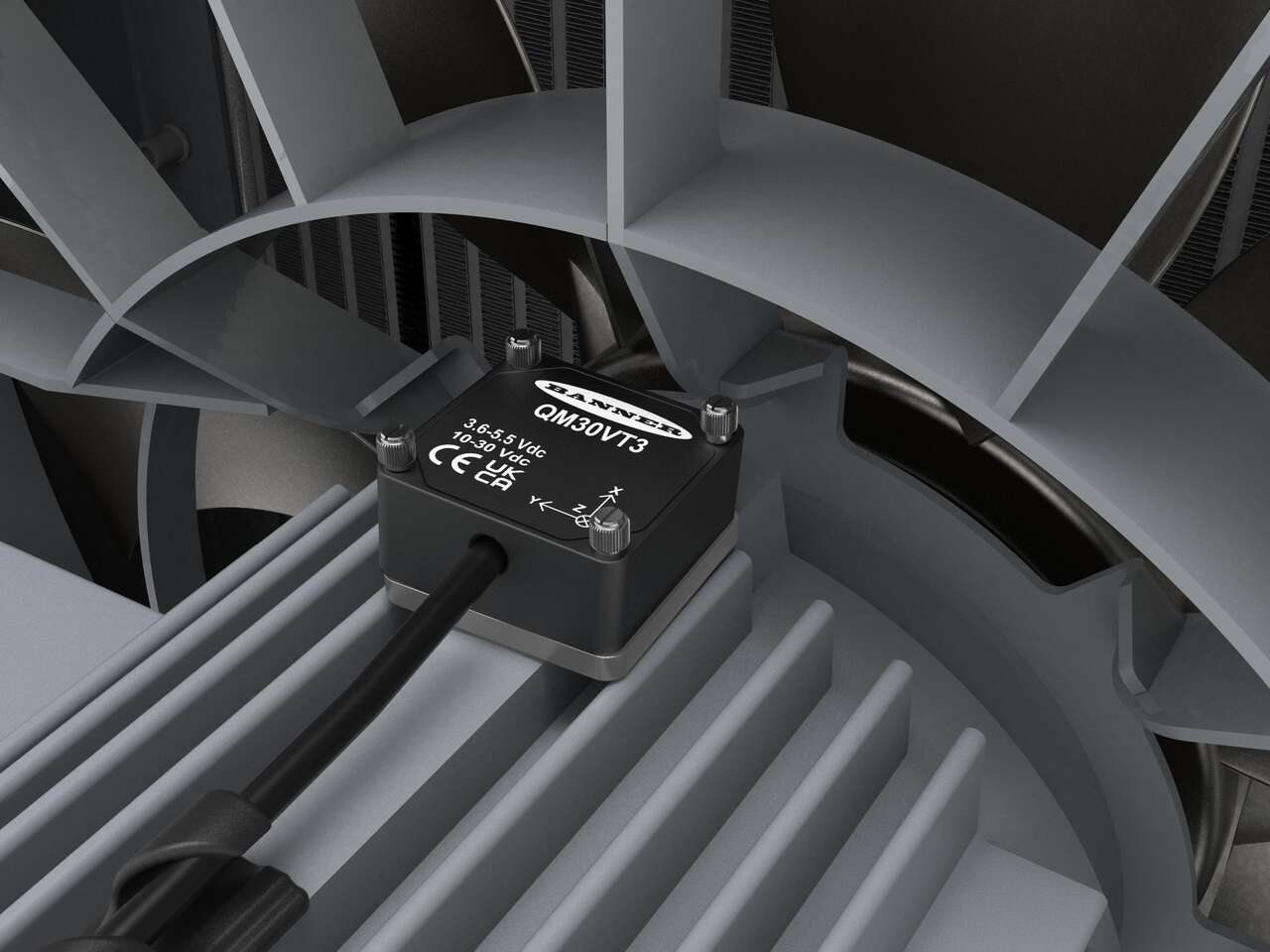

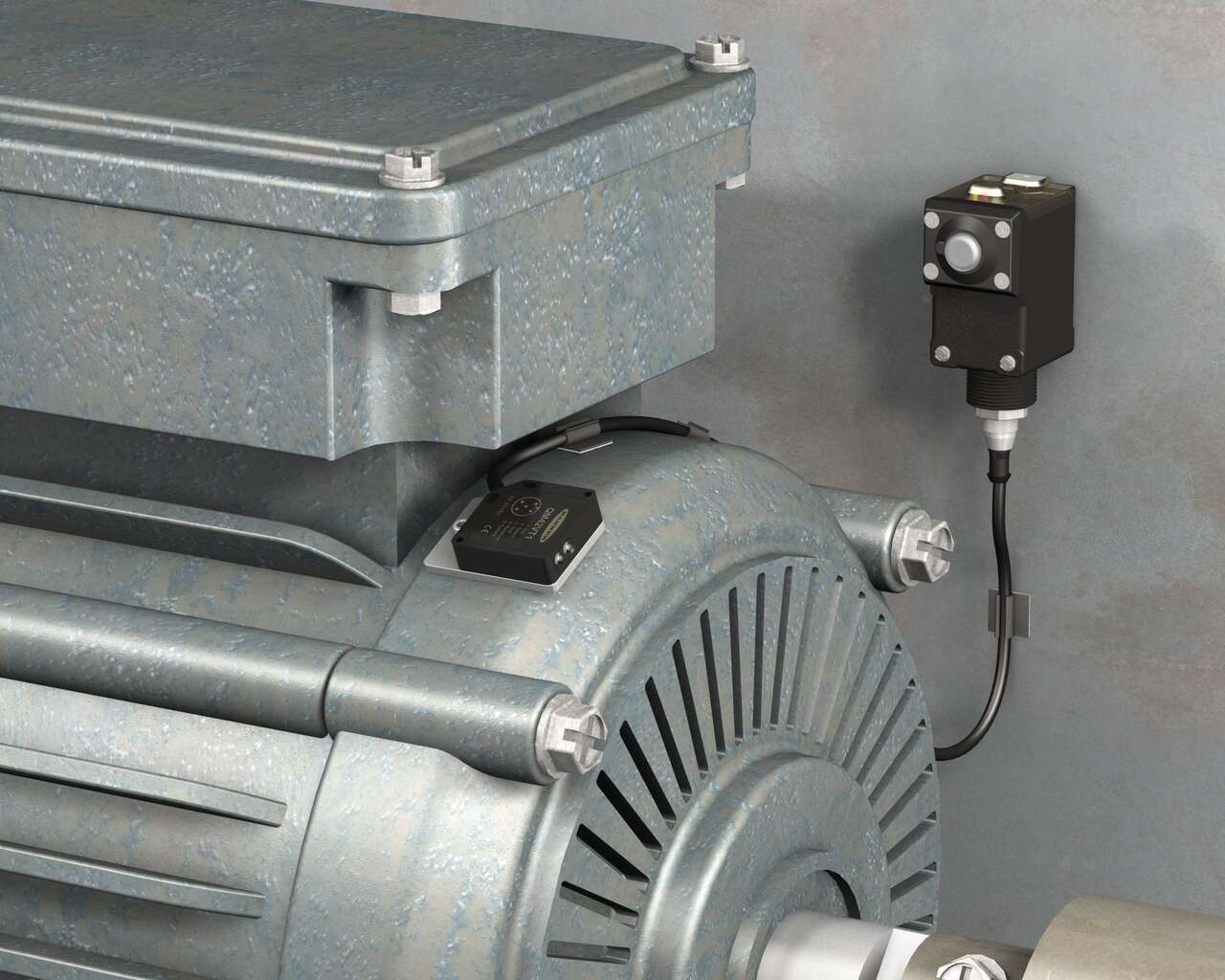

Predictive Maintenance and Condition Monitoring

Predictive maintenance enables users to more accurately anticipate when machine maintenance will be needed based on real-time data from the machines themselves.

-

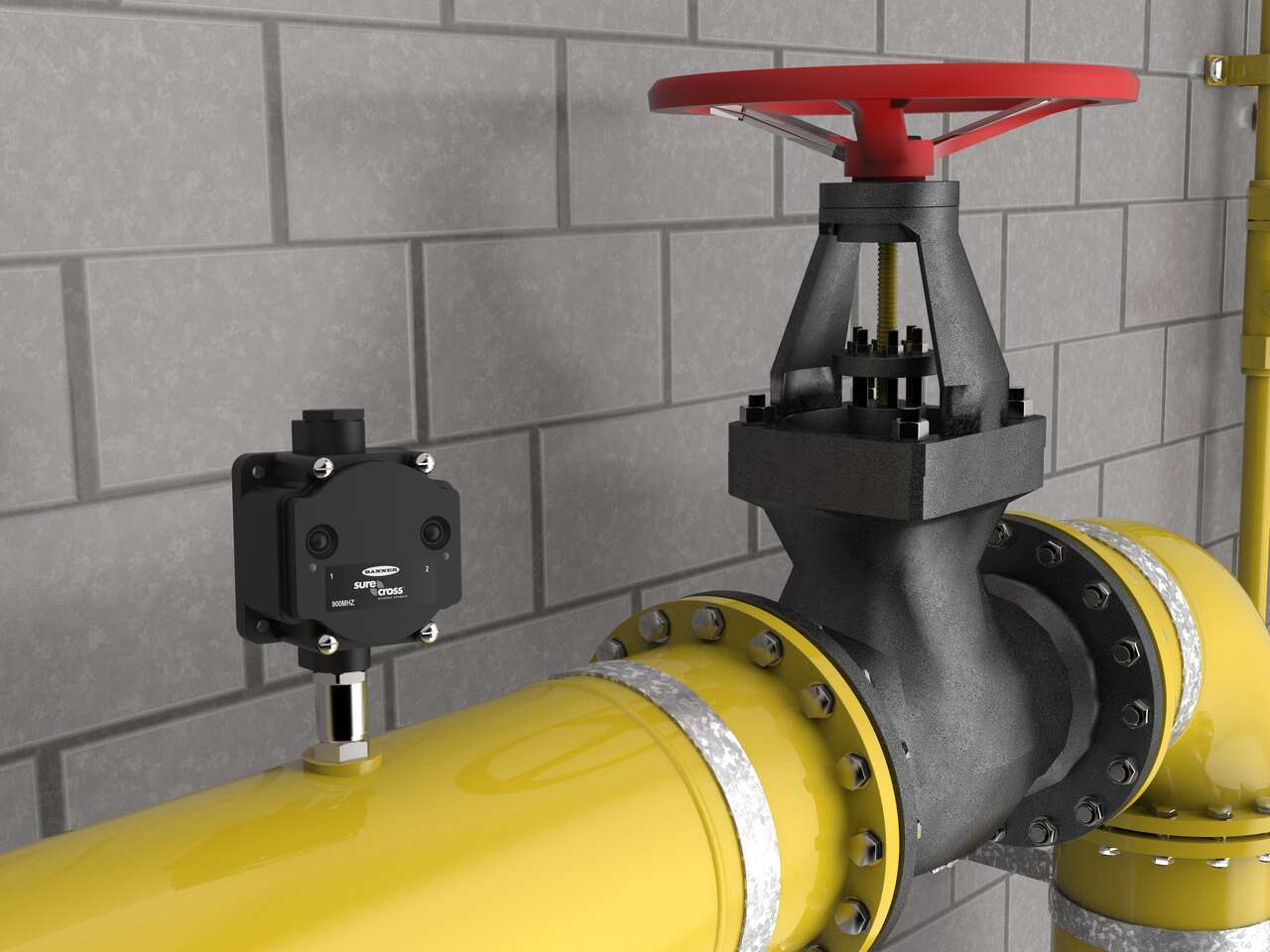

Remote Monitoring

Remote monitoring enables increased visibility into the performance and efficiency of machines, processes, and people.

-

Overall Equipment Effectiveness (OEE)

Remote monitoring capabilities provide data for OEE calculations, making it easier for manufacturers to identify and remedy causes of waste within their facilities.

-

Factory Communication

IIoT technologies enable better communication throughout the factory and streamline processes for machines and people alike.