Outsmart Compressed Air Downtime and Energy Loss

Ensure Reliable and Efficient Compressed Air Delivery to Equipment

The Asset Monitoring System for Air Compressors ensures your equipment that relies on compressed air continues to deliver consistent, high-quality output with maximum uptime. It installs easily and works with most air compressors, new or old, regardless of type or brand. Providing value on day one, maintenance and operations teams can immediately leverage data from the Asset Monitoring System to quickly identify and solve problems that reduce productivity and waste energy.

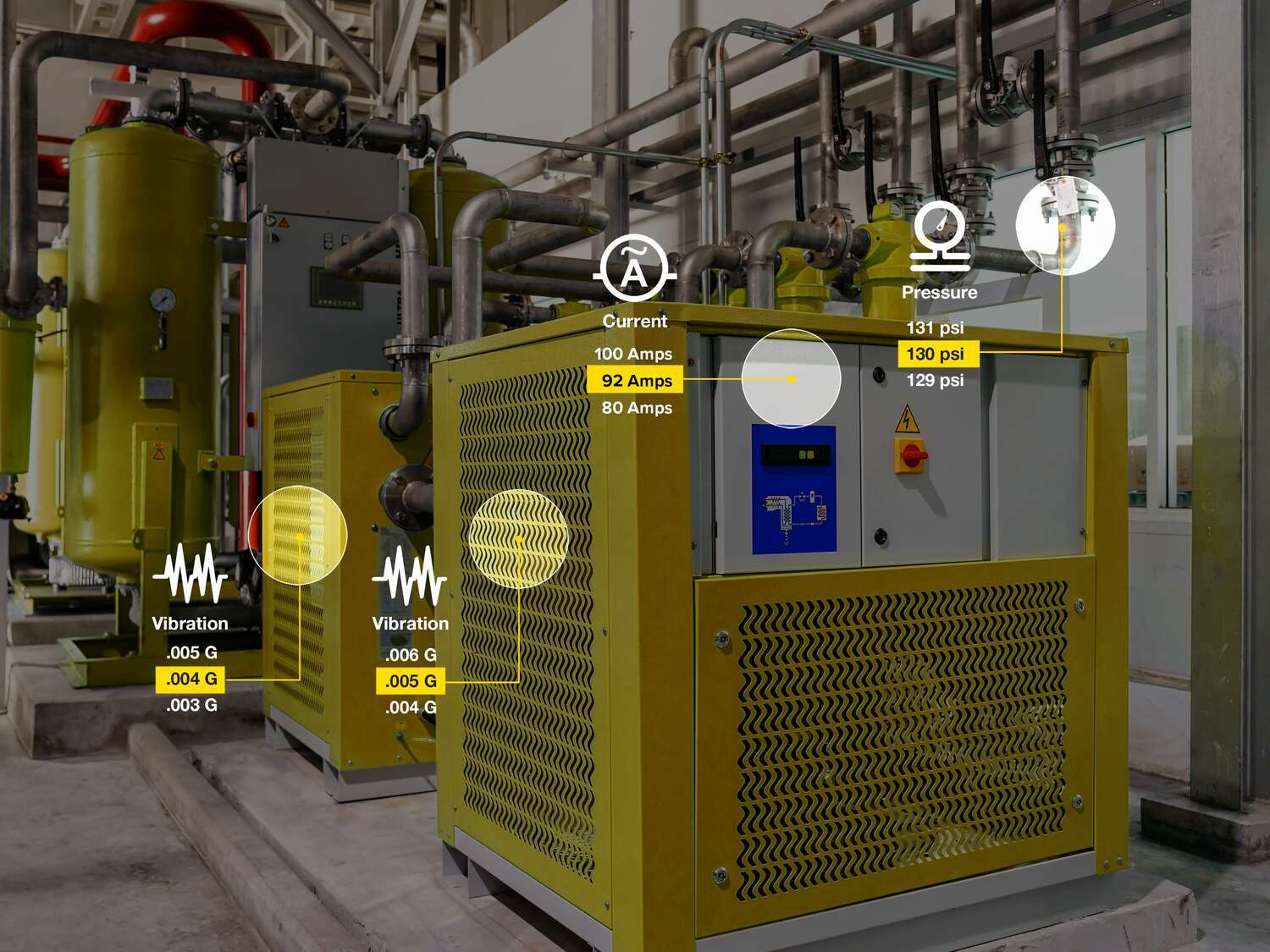

Greater machine uptime is achieved by predicting potential breakdowns through leading indicators of equipment failure such as excessive heat, vibrations, current draw, and pressure loss. By watching air compressors around the clock, the Asset Monitoring System frees your maintenance teams to be deployed when and where they are needed most. Critical system information is easily viewed locally via the onboard touchscreen display, or can be sent to the cloud for remote observation. Either way, the Asset Monitoring System provides a clear, easy-to-access, comprehensive overview of your compressed air system’s status.

The Asset Monitoring System has what you need to start monitoring your compressed air system: sensors, asset monitoring gateway, cables, power supply, and mounting hardware.

Our approach to monitoring your air compressors is easy: start small. Many efforts to glean equipment data never leave the ground because they are too hard, take too many people to implement, or simply cost too much. Everything you need to get started comes in one box so you can start monitoring within minutes.

Step 1:

Install the Asset Monitoring Gateway

The heart of this system is the easy-to-use touchscreen asset monitoring gateway. Once it is mounted near your air compressor, you can begin the simple setup process.

Step 2:

Connect and Commission the System

Connect the sensors to the gateway monitor one at a time by following a simple configuration process on the screen, no PC or special training required.

Step 3:

Install Sensors

Install the sensors where needed and connect them to the asset monitoring gateway. They’re automatically detected so you'll be up and running in no time.

Asset Monitoring Gateway

This is what all sensors plug into. The touchscreen display provides easy access to data, sensor control, and setup.

These are installed on the electric motor and compressor pump. The technology in our system can indicate when readings are outside normal operation boundaries, providing early notification about potential problems.

This sensor is connected to one power leg wire on your compressor motor. It can help you see excessive current draw, which could be an indicator of a larger problem.

When connected to a line, this sensor can instantly recognize pressure drops, which can be indicative of leaks in the system.

Accessories Included in Each System

Power supply: This powers the entire system.

Cables: The included cables cover most applications. Additional cable lengths are available separately.

Mounting hardware: Screw-in mounting brackets allow convenient positions of the asset monitoring gateway and sensors. Other types of mounts and brackets are available separately.

Our Machine Learning Makes Troubleshooting Easy

Banner’s Vibe-IQ monitors equipment health, using machine learning to identify when assets exceed predefined parameters and require maintenance. This approach increases uptime, reduces maintenance cost through more effective part inventory management and maintenance scheduling, and simplifies troubleshooting by eliminating the complexity of traditional data analysis.

How Vibe-IQ works:

- Monitors each motor using a machine learning algorithm that determines necessary values and sets control limits with limited operator interaction

- Continually monitors RMS velocity, RMS high frequency acceleration, and temperature

- Determines if motors are running or not and uses data only from running motors for setting values and alerting

- Collects data for trending, analysis, and defining acute versus chronic issues

Start Monitoring Your Air Compressor System

That's all it takes to get started. If you have questions along the way we've created videos that will guide you through every step in the process.

Now that your asset monitoring system is set up and operating, you can begin monitoring your air compressor in real-time. You are on your way to migrating from breakdown maintenance to predictive maintenance.

Order Your Asset Monitoring System for Air Compressors

The ordering process is simple, too. Choose your System (Ethernet or cellular), then add on any extra brackets you need (the kit comes with screw-on brackets).

speak with an expert

Have Questions? We Can Help.

Get a personalized virtual or on-site demonstration of the Assent Monitoring System for Air Compressors. Explore key features, expanded application examples, and get expert answers to your technical questions. Experience cost-effective, reliable solutions designed to increase uptime and enhance productivity. Contact us today at 1-888-3-SENSOR (736767) or by the form below and see for yourself why Banner Engineering is the trusted choice for your air compressor monitoring needs .