-

Products

-

Sensors

-

Ultrasonic Sensors

-

QT50U 8 m Range Chemical Resistant Ultrasonic Sensor

8 m Range Chemical Resistant

- Senses extended range of up to 8 m

- Features ultrasonic dead-zone of only 2.5% of the total range—75% less than comparable products

- Available in analog or discrete dc models and in ac/dc universal voltage models with electromechanical relay output

- Features a completely sealed, shock-resistant housing that is ideal for monitoring levels of liquids as well as solids

- Uses a narrow sensing beam to detect targets at long range within confined areas—such as a storage tank—without interference from the tank walls

- Available in chemically resistant models with a Teflon coating to protect the transducer

- Compensates for temperature, for greatest sensing accuracy

- Simplifies setup with push-button and remote TEACH-mode programming

- Shows status during setup and operation, using highly visible LEDs indicators

QT50U 8 m Range Chemical Resistant Ultrasonic Sensor

Applications

-

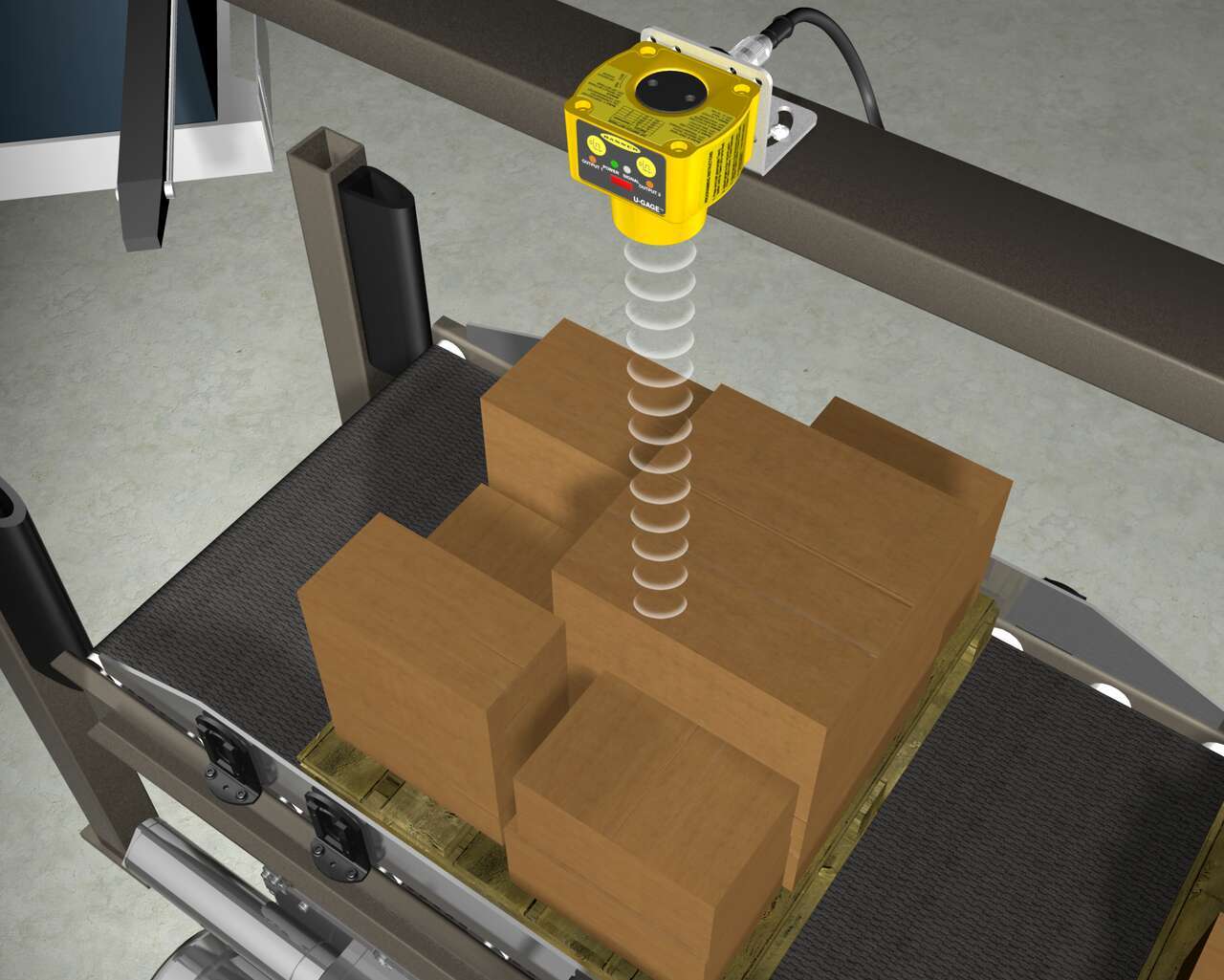

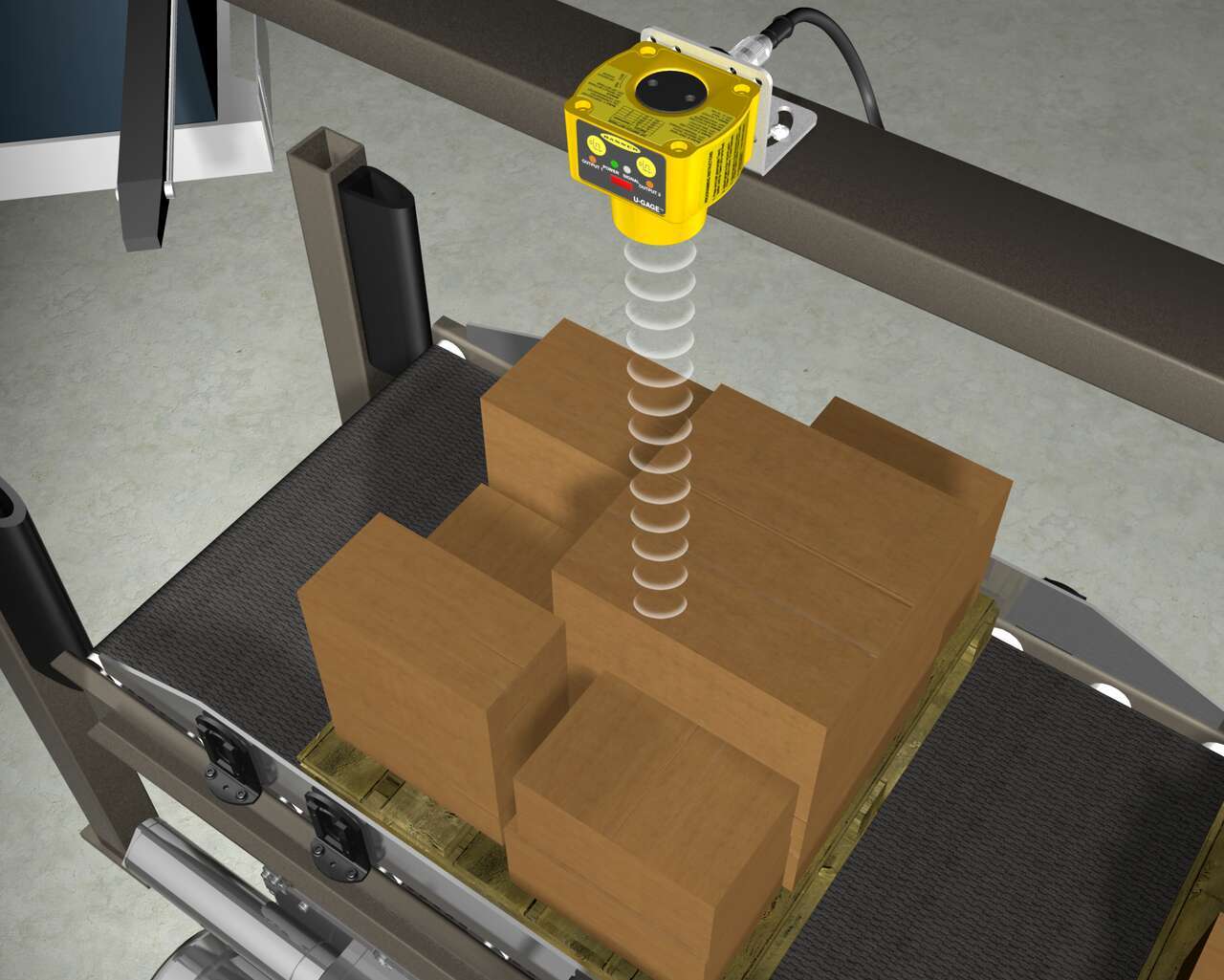

An ultrasonic sensor will provide reliable pallet detection. Ultrasonic sensors emit sound waves and “listen” for the return echo of the sound wave bouncing off the target. The sensor can be taught a reliable background, in this case the conveyor, and will listen for sound waves returning from the conveyor. Any object getting between the sensor and the conveyor will be detected, causing the output to switch.

-

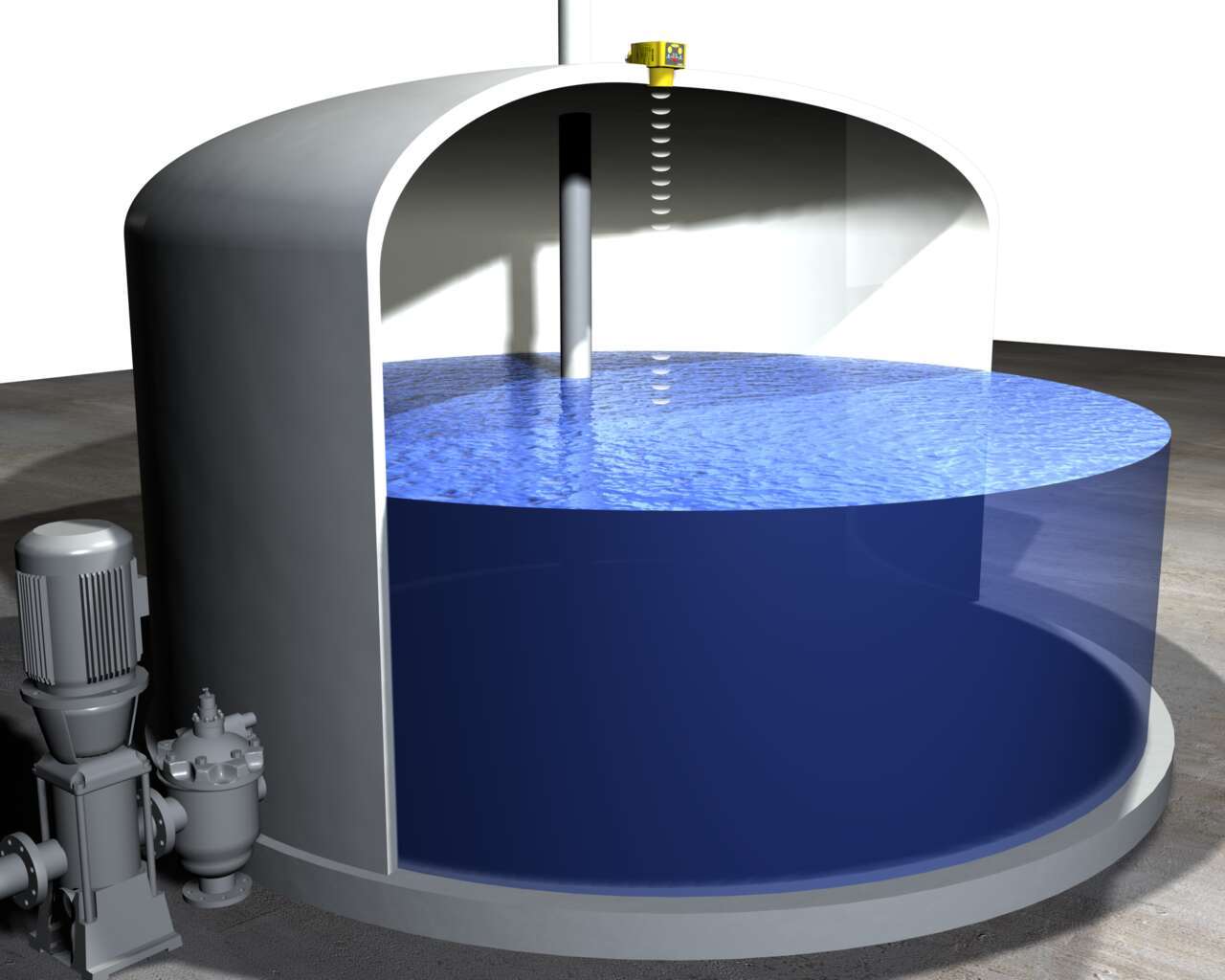

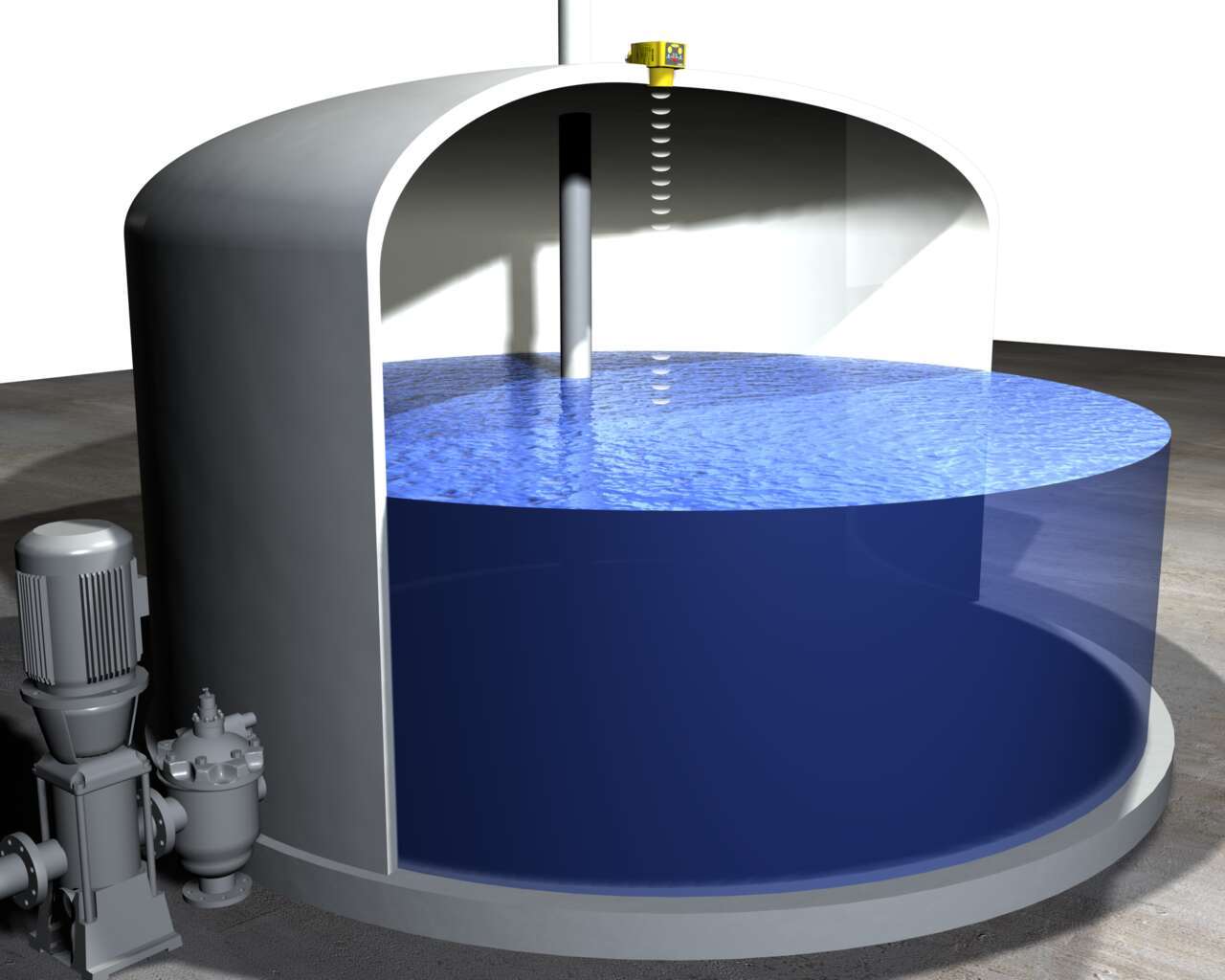

Banner’s U-Gage QT50U ultrasonic sensor excels at the most challenging level applications, bouncing sound off any solid surface—even those that may vary in consistency or contrast. The sensor is available with a Teflon-coated transducer cover, making it resistant to harsh chemicals and suitable for the food and beverage industry. Ultrasonic sensors are able to provide accurate monitoring of pump-controlled tanks by sending a continuous signal to measure the current tank depth.

-

Banner’s U-GAGE QT50U ultrasonic analog long distance sensor has a narrow sensing beam that works in confined areas, such as the tank, without interference from the tank walls and senses with an extended range up to 8 m. The ultrasonic sensor can be mounted to the center so that the beam spreads over the tank to detect the fluid level without interference, while signaling when to pump out excess liquid and pump in additional liquid.

-

Sure Cross Nodes with FlexPower and Banner U-GAGE QT50U analog sensors quickly and easily facilitate these monitoring requirements without new construction and wiring. The FlexPower Node transmits the sensor data back to the Gateway device. When using a Gateway Pro, data is logged and alerts can be sent when fluid levels reach critical levels.

-

Detecting Pallets with Irregular Loads

An ultrasonic sensor will provide reliable pallet detection. Ultrasonic sensors emit sound waves and “listen” for the return echo of the sound wave bouncing off the target. The sensor can be taught a reliable background, in this case the conveyor, and will listen for sound waves returning from the conveyor. Any object getting between the sensor and the conveyor will be detected, causing the output to switch.

-

Level Monitoring for Washdown Environments

Banner’s U-Gage QT50U ultrasonic sensor excels at the most challenging level applications, bouncing sound off any solid surface—even those that may vary in consistency or contrast. The sensor is available with a Teflon-coated transducer cover, making it resistant to harsh chemicals and suitable for the food and beverage industry. Ultrasonic sensors are able to provide accurate monitoring of pump-controlled tanks by sending a continuous signal to measure the current tank depth.

-

Liquid Level Monitoring

Banner’s U-GAGE QT50U ultrasonic analog long distance sensor has a narrow sensing beam that works in confined areas, such as the tank, without interference from the tank walls and senses with an extended range up to 8 m. The ultrasonic sensor can be mounted to the center so that the beam spreads over the tank to detect the fluid level without interference, while signaling when to pump out excess liquid and pump in additional liquid.

-

Wireless Monitoring Retrofit in a Pre-Certified Facility

Sure Cross Nodes with FlexPower and Banner U-GAGE QT50U analog sensors quickly and easily facilitate these monitoring requirements without new construction and wiring. The FlexPower Node transmits the sensor data back to the Gateway device. When using a Gateway Pro, data is logged and alerts can be sent when fluid levels reach critical levels.

Incomplete Checkout

Share Your Checkout Experience

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

Downloads

English Documents

English Documents

Have a Technical Question?

Have a question about this product series? Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.