Streamline Labeling Process with a Fixed-Field Sensor

Challenge

Solution

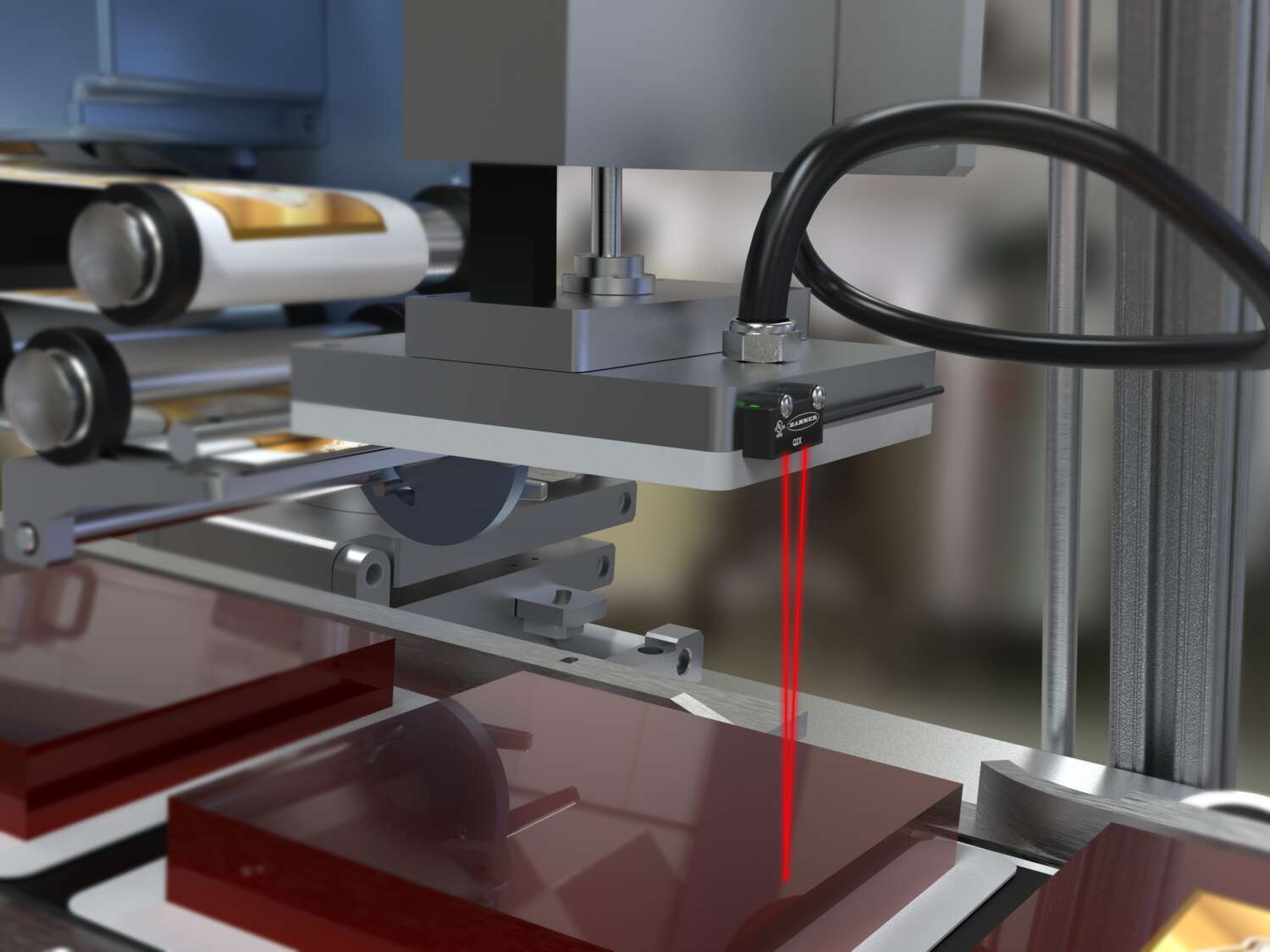

A miniature Q2X fixed-field sensor can be fitted onto the labeling machine’s tamp head to sense targets at a fixed distance. As a product moves by on the conveyor, the tamp head receives a label and indexes downward. When the product comes within range of the fixed field sensor, it slows the tamp head down until it makes contact where it then presses down with the appropriate pressure to apply the label, and then rises to repeat the process.

For facilities that label products of varying size, this sensor application eliminates the need to make tedious manual height adjustments to the machine between labeling runs. It also allows for greater packaging height variance within a labeling run, as the sensor ensures that the tamp head applies the label at the target’s actual height on an individual basis.