Automotive: Powertrain Solutions

-

Vision Sensor to Read QR Codes

Vision Sensor to Read QR Codes

iVu Plus BCR Gen 2 with 25 mm Micro Lens replaces hand held barcode readers to collect data from dense, difficult-to-read QR codes on vehicle transmissions. A WL50S high-intensity LED spot light illuminates the target area.

-

Operator Guidance Solution

Operator Guidance Solution

A Henshaw customer manufactures drivetrain and powertrain systems for the automotive industry. The company had experienced productivity losses due to errors in the assembly of transmission valve bodies. Henshaw was tasked with developing a system that would reduce errors and improve the assembly process.

-

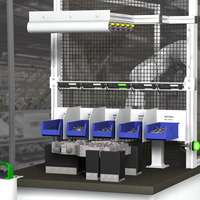

Improving Production with Pick-to-Light Systems

Improving Production with Pick-to-Light Systems

A Banner wireless solution is a simple way to optimize inventory, reduce errors, and minimize waste. Each Sure Cross Performance Node with I/O Mapping can be equipped with up to six EZ-LIGHT operator indicator lights. The Sure Cross Gateway is conveniently located at a central location where maintenance personnel and management can monitor the parts consumption throughout the site.

-

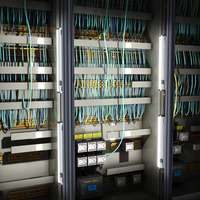

LED Lights Illuminate Control Cabinet

LED Lights Illuminate Control Cabinet

Operators access machine systems through the control cabinet and need Intense illumination of the cabinet facilitates for maintenance and management.

-

Superior Light Distribution with LEDs

Superior Light Distribution with LEDs

American Hoffmann Corporation chose WLB32 LED light bars to illuminate work areas, enclosures and control cabinets, replacing fluorescent light fixtures. The superior light distribution offered by the WLB32 LED lights lights, as well as the ease of installation were key factors in the company's decision.

-

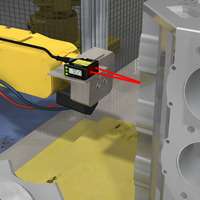

Thread Hole Detection

Thread Hole Detection

The WORLD-BEAM QS30's narrow laser beam can prevent these mistakes from happening it is necessary to verify, from a distance, that bolt threads have been cut into holes in a manifold.

-

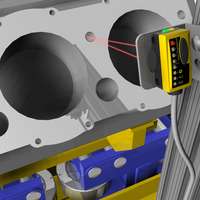

Engine Block Part-In-Place Detection

Engine Block Part-In-Place Detection

Banner’s LE550 laser sensor is ideal for part-in-place verification processes. It is reliable, and extremely accurate for small part-in-place verification from long distances. The LE550 measures for 3 mm thickness using the digital output, ensuring that the retaining clip is present and the engine block is in the correct place.