Pharmaceutical and Medical: Primary Packaging

Primary Packaging in the Pharmaceutical and Medical Industry

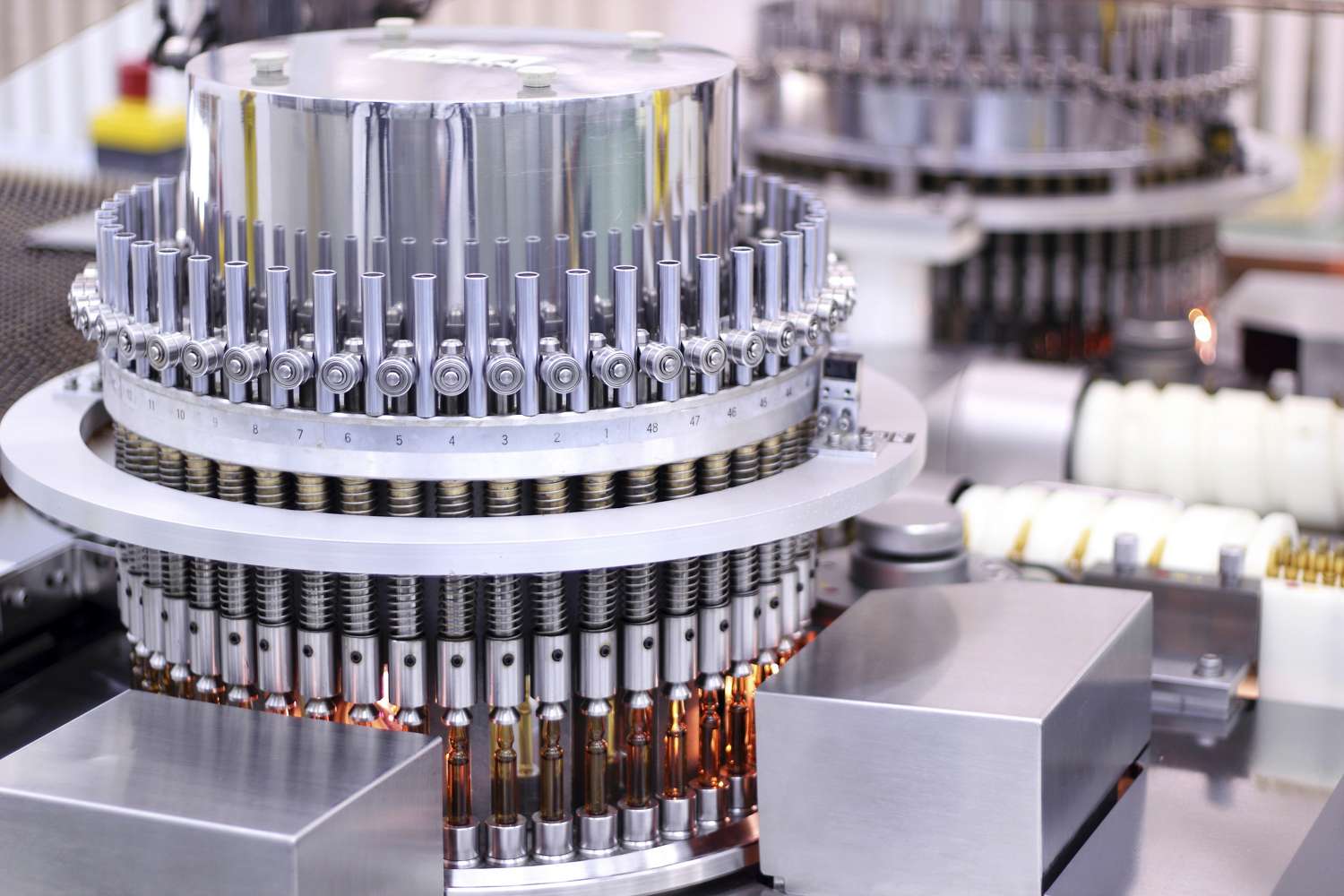

In the pharmaceutical industry, filling the correct amount of a product into the correct container is critical. Processes are automated and operate at high speeds.

Used on bottle fillers, tablet dispensing machines, desiccant dispensing machines, blister packaging machines, and other unit dosage packaging equipment, Banner sensors solve a number of challenging applications. They can be used to verify bottle position at filling stations and to monitor the dispensing and hopper levels of drugs. Vision systems verify that blister packs are completely and correctly filled and inspect stopper position and height to ensure that containers are sealed properly. Clear object detection sensors reliably detect clear glass or plastic bottles, vials, syringes, and ampoules used to package liquid dosage products. Our unique liquid detection sensors inspect fill level to ensure products are not under filled or over filled.

Featured Applications