Banner Engineering Vibration Solutions for AWS IoT

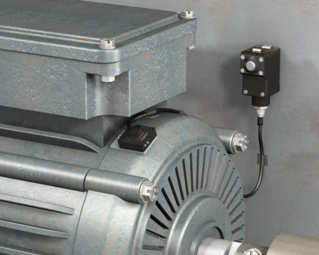

Identify equipment problems early before a failure can occur by monitoring the health of motors, fans, pumps, and other rotating equipment. Banner’s wireless vibration monitoring solutions make it easy and cost effective to monitor a variety of vibration characteristics and set warning and alarm thresholds, as well as collect vibration data over time for trending and analysis.

By pairing Banner wireless vibration sensors with the DXM Wireless Controller running a machine learning algorithm, customers can quickly identify baseline vibration levels and generate alerts when thresholds are exceeded due to misaligned components, or early bearing failure. This direct insight into equipment performance provides greater opportunities for predictive maintenance, increasing uptime, and offers an ideal entry point for your Industry 4.0 initiatives.

- Choose your Sensor and Gateway

- DXM700-B1R1 or DXM1200-B1R1 gateway

- Q45VA All-in-One Vibration Sensor or Q45VTP node with QM30VT vibration sensor

- Configure your gateway with Banner’s machine learning script for vibration analysis

- Follow our step-by-step guide for loading our ML script and configuration files onto your DXM controller

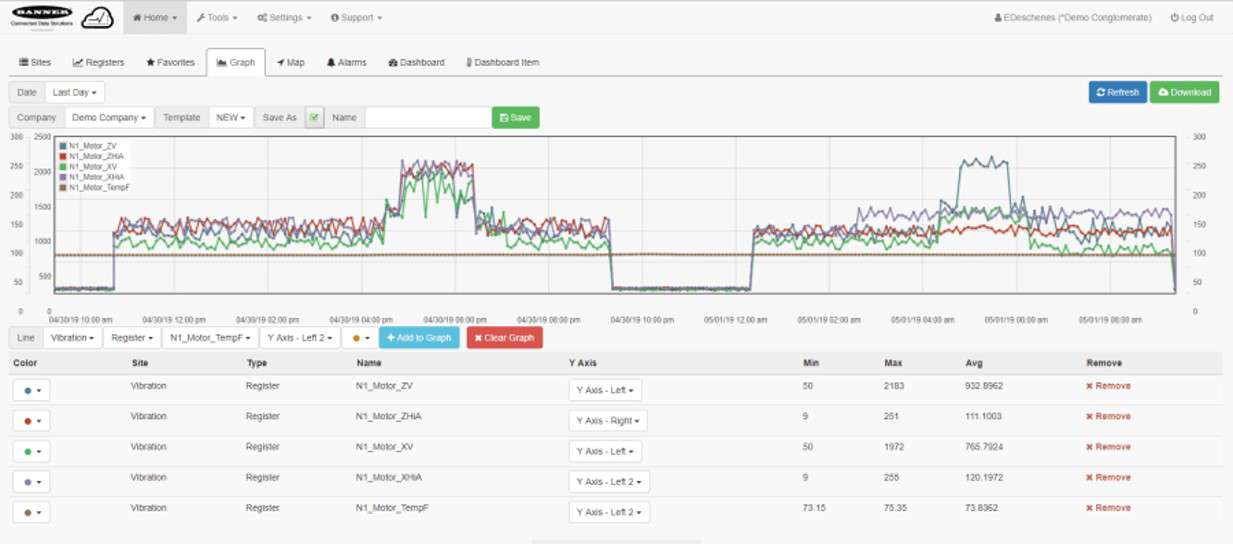

- Connect to the Cloud using Banner Cloud Data Services, or point your data directly to AWS IoT Core

- Validate your data immediately and begin grouping and graphing your asset data in minutes on Banner Cloud Data Services. Easily configure SMS and email alerts to notify you when there’s a problem with your equipment

- Follow our guide for mapping your data into AWS IoT Core and quickly launching your AWS-based IIoT Solution

HOW DOES IT WORK?

- Banner vibration sensors measure several vibration characteristics and wirelessly sends the data to the DXM controller

- The DXM controller collects the data and can be programmed to automatically establish baselines and set warning and alarm thresholds

- The DXM controller collects data and transmits to the Cloud via local ethernet or cellular connection

- Use Banner CDS for pre-configured dashboard and alerting functionality, or plug your data into AWS IoT Core to start your AWS IoT journey

WHAT TO MONITOR

Vibration Characteristics:

- RMS velocity = general machine health

- High frequency RMS acceleration = early bearing wear

COMMON EQUIPMENT

- Motors

- Pumps

- Exhaust fans

- HVAC Compressors

- Gear boxes

- Spindles

- Any rotating equipment

Gateways

The DXM controller series integrates Banner's wireless radio, cellular and Ethernet connectivity, and local I/O to provide a platform for the Industrial Internet of Things (IIoT).

Q45 All-in-One Series for Predictive Maintenance

Q45 Series all-in-one devices combine a wireless node, sensor, and battery power supply in one easy-to-deploy device that monitors assets and equipment in remote and hard-to-access locations.

2-Axis Vibration Sensors

Line-powered QM30VT 2-axis vibration and temperature sensors detect changes in machine health and performance, helping identify potential problems early.