Machine Status, Uptime, Utilization

Learn how to get this information and more out of your tower light.

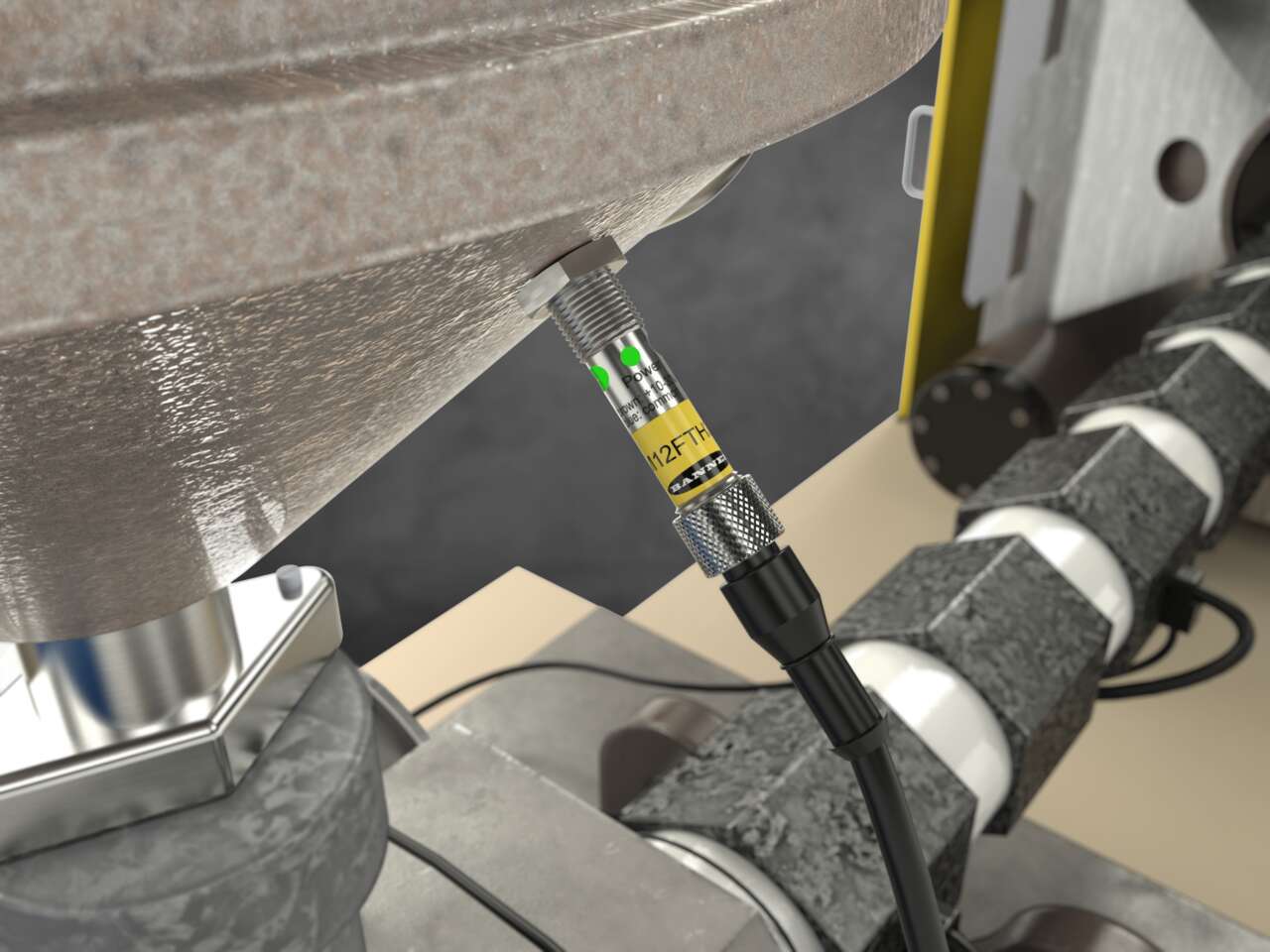

Tower Light Monitoring

Tower lights typically include red, yellow, and green light segments to communicate machine status to workers nearby, but have you ever considered what you might be able to learn from analyzing the time series of these machine conditions?

Track Machine Uptime and Utilization

For instance, green light segments are often used to show that a machine is online and working as planned. By monitoring this light segment, you can track uptime and utilization of the machine, giving you the necessary information to help manage and forecast the capacity of your equipment. Gain further insight with Banner's Cloud Data Services (CDS) software, a web-based platform that allows users to access, store, protect, and export critical data collected by wired and wireless sensors. When comparing data from multiple machines you can begin to find differences in performance and analyze trends over time for better, data-driven decisions in the long term.

Tower lights mounted on top of machines to communicate their statuses.

TL50 provides clear status indication on a conveyor.

Use Data for Predictive Maintenance

Yellow light segments often indicate that maintenance needs to be performed but has not yet reached an all-out failure state. Analyzing the time series of this data can not only help maintenance managers schedule service on equipment, but they can track how long machines spend in this state and correlate it with other factors, such as productivity of the machine and the quality of the parts its producing. Understanding how often maintenance needs to be performed can also help inform plant managers as to when equipment needs to be upgraded or replaced entirely.

Monitor Machine States

Red light segments are sometimes considered the most important color to monitor, since they typically indicate when a machine has stopped working. Regardless of why the machine has stopped, monitoring how often this happens can help continuous improvement teams with their efforts to make changes to equipment to improve uptime or reliability. Again, monitoring this data across multiple machines will help inform plant managers of performance from machine and understand where the bottlenecks are in the operation.

TL70 tower lights surround a robotic palletizer to reflect status at a glance.

Every machine is unique, therefore colors outside of the traditional green, yellow, and red may be required to indicate additional conditions. For example, a white tower light may indicate that a machine cycle has been completed. By monitoring this, a company could then understand the throughput of each machine in real-time. They would also be able to tell the time between cycles to potentially help improve productivity by reducing the time between part runs. If a machine operator cannot solve a small problem, they may use a blue light to capture the attention of the floor manager. Analyzing this condition could inform staff of training needs to help reduce the occurrence of these conditions. In-line tower lights have audible segments that would sound an alarm when an issue arose, prompting workers to troubleshoot the proper machine. Operators could use the data collected in this condition to measure downtime and identify ways to increase efficiency.

Unlock the valuable data that tower lights provide to become more informed, more efficient, and more productive.