-

SnapSignal

-

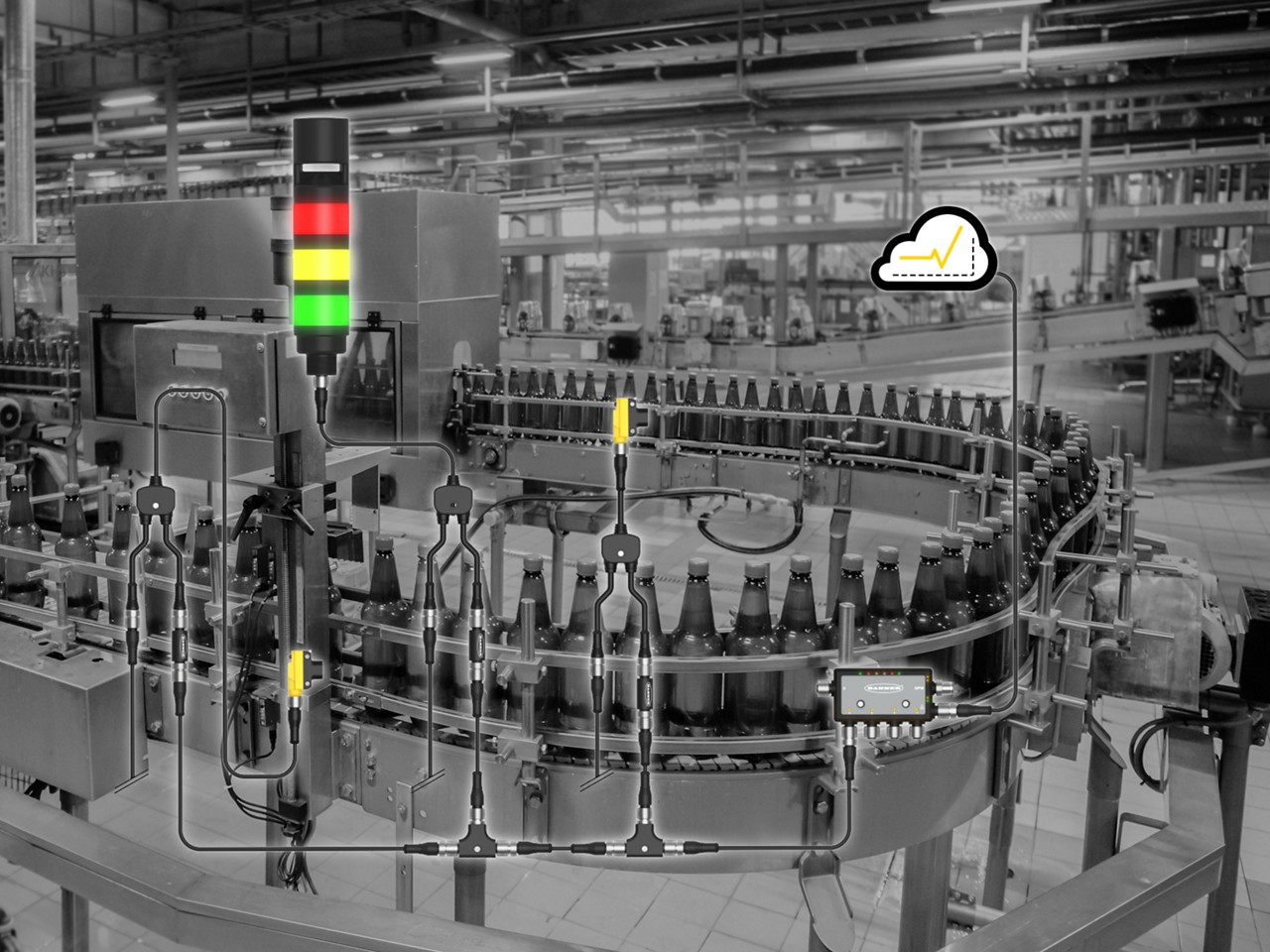

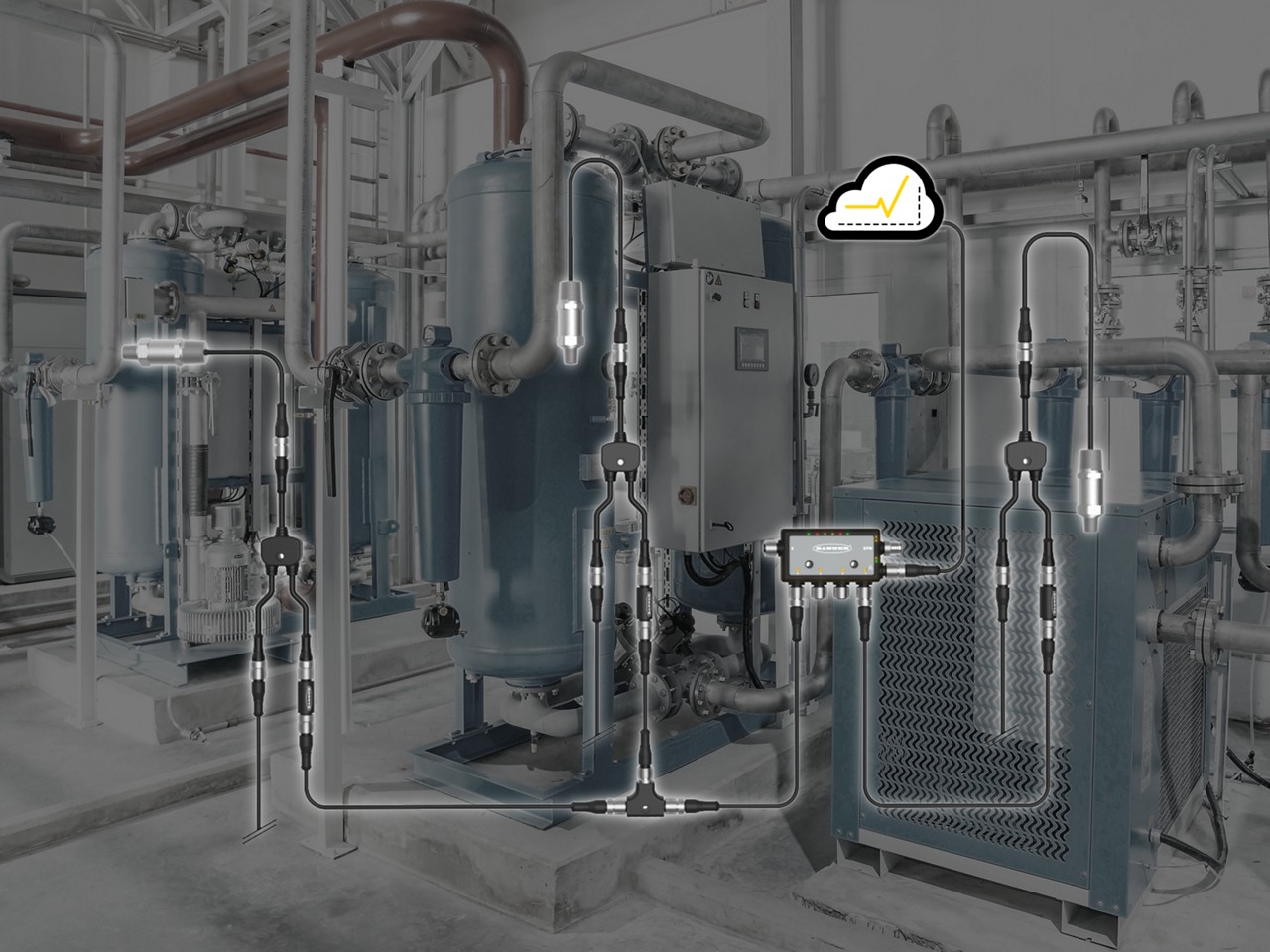

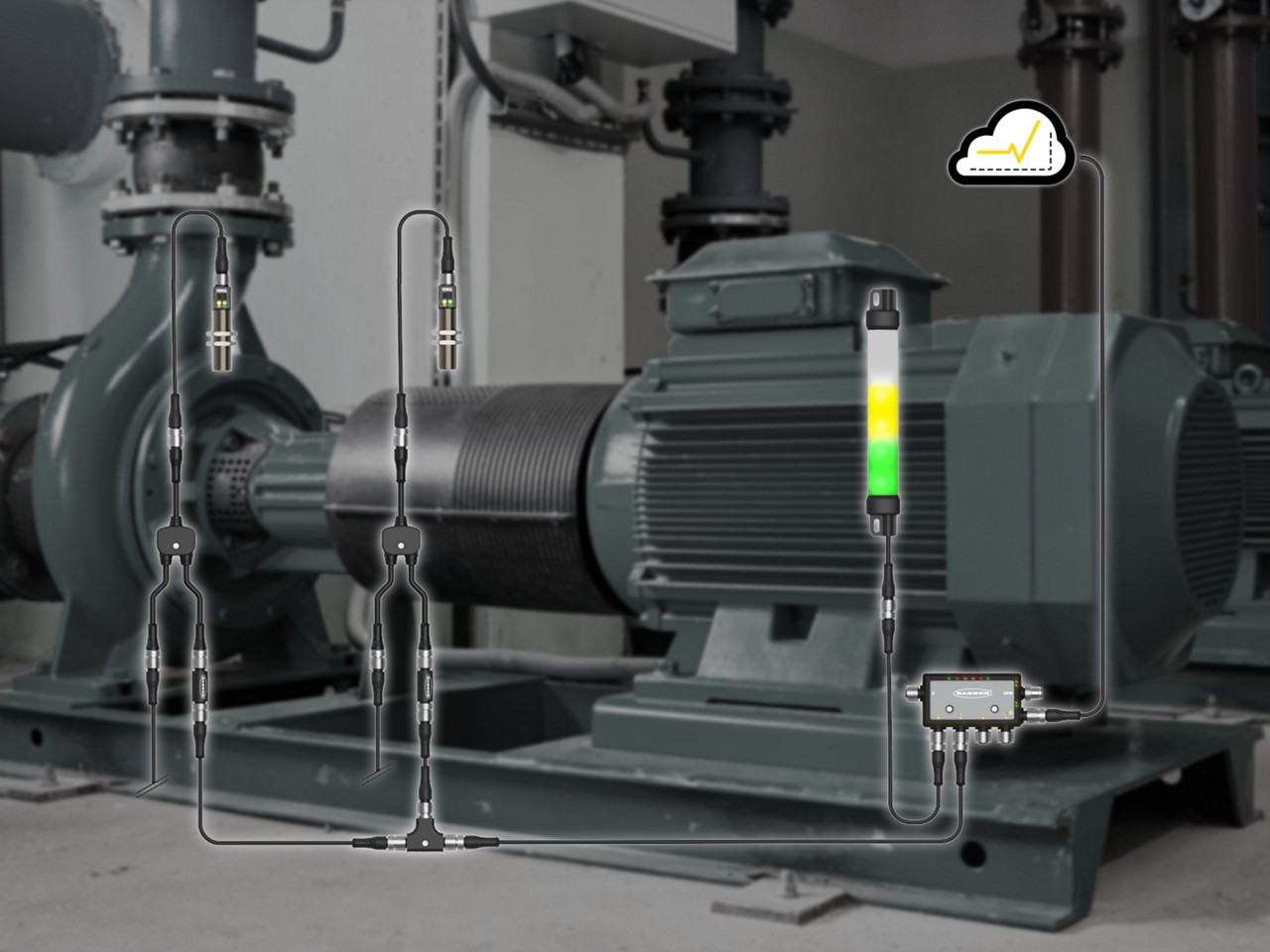

Process Critical Assets

IIoT Made Easy

Banner’s Snap Signal family of plug-and-play products represents a new way to unlock your valuable machine data.

Monitor Your Factory Data in a Snap

Keep Your Process Critical Assets Running at Peak Performance

Snap Signal Products Help You Capture the Information You Need and View It from Anywhere

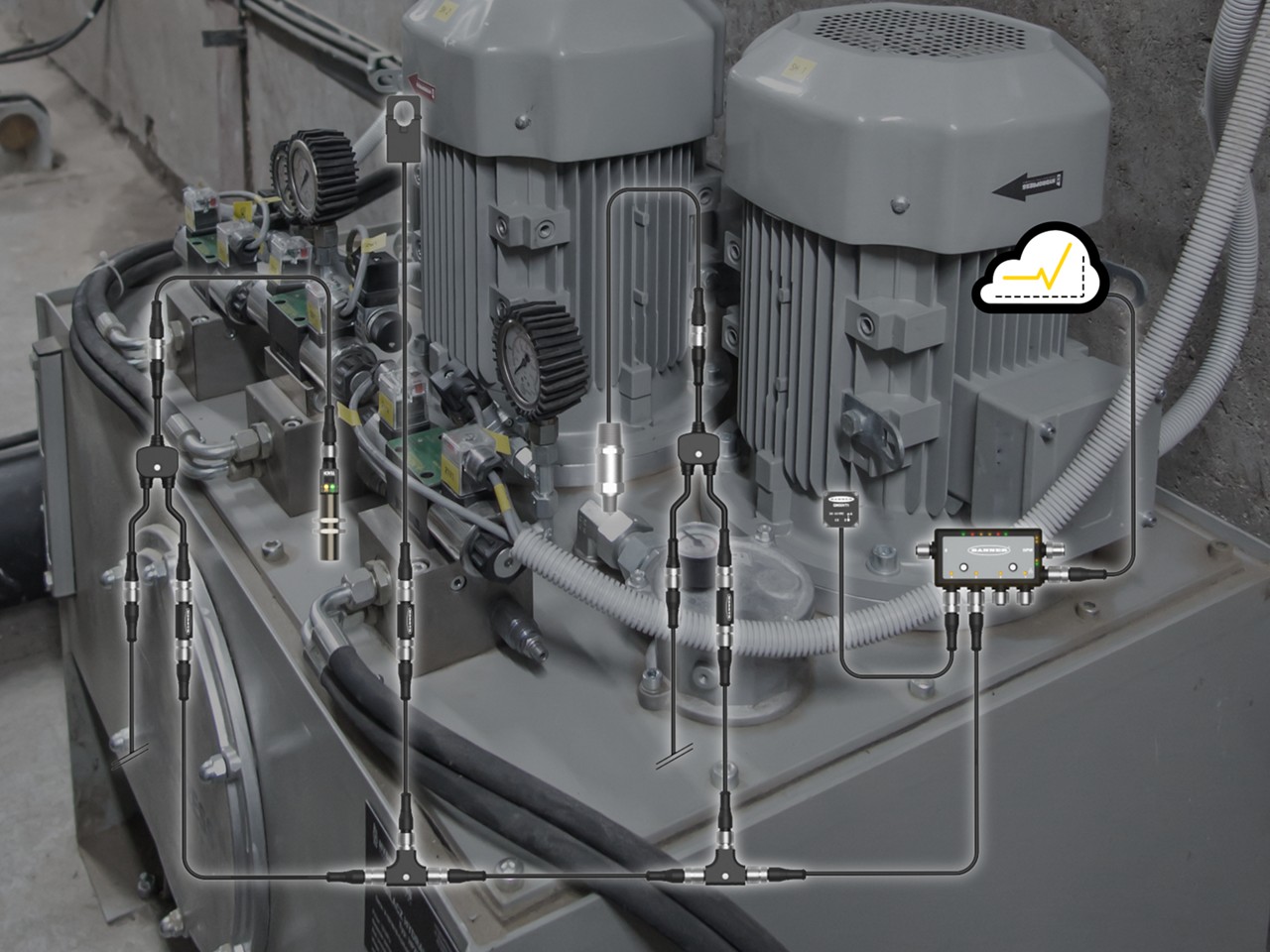

Easily monitor the pressure, current, temperature, and motor vibration/temperature of many process-critical assets in your facility. Snap Signal products connect sensors of various types and convert their signals to Serial data for real-time condition monitoring. For example, there is a piece of industrial equipment or machine that is running and begins to slowly fail but production has not been affected. But an overheating motor in the asset could lead to a critical failure that would stop production for an extended period of time. Condition monitoring makes it possible to ensure that all equipment is working at optimal efficiency, and to detect and address potential maintenance issues before they lead to costly production downtime.

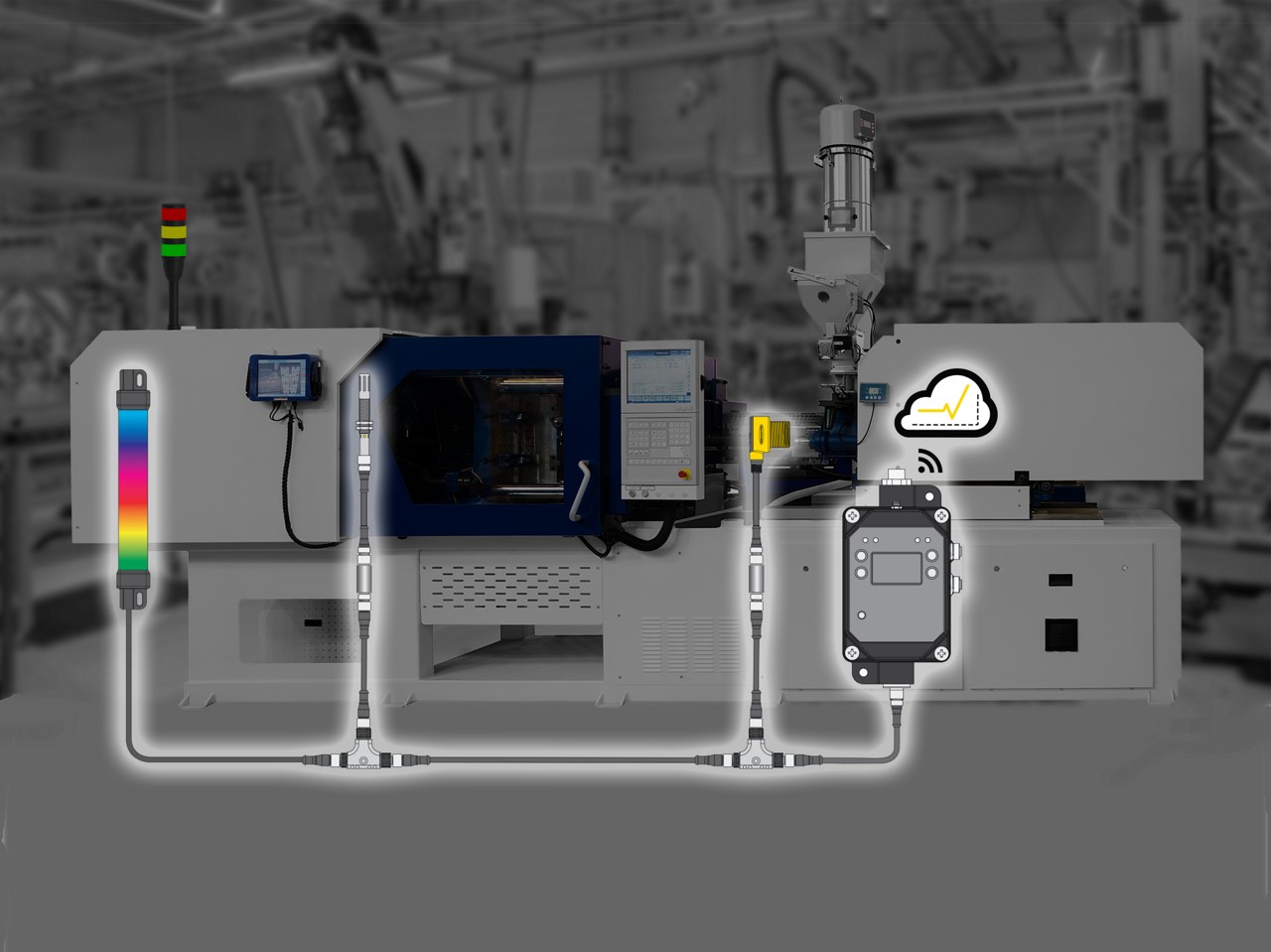

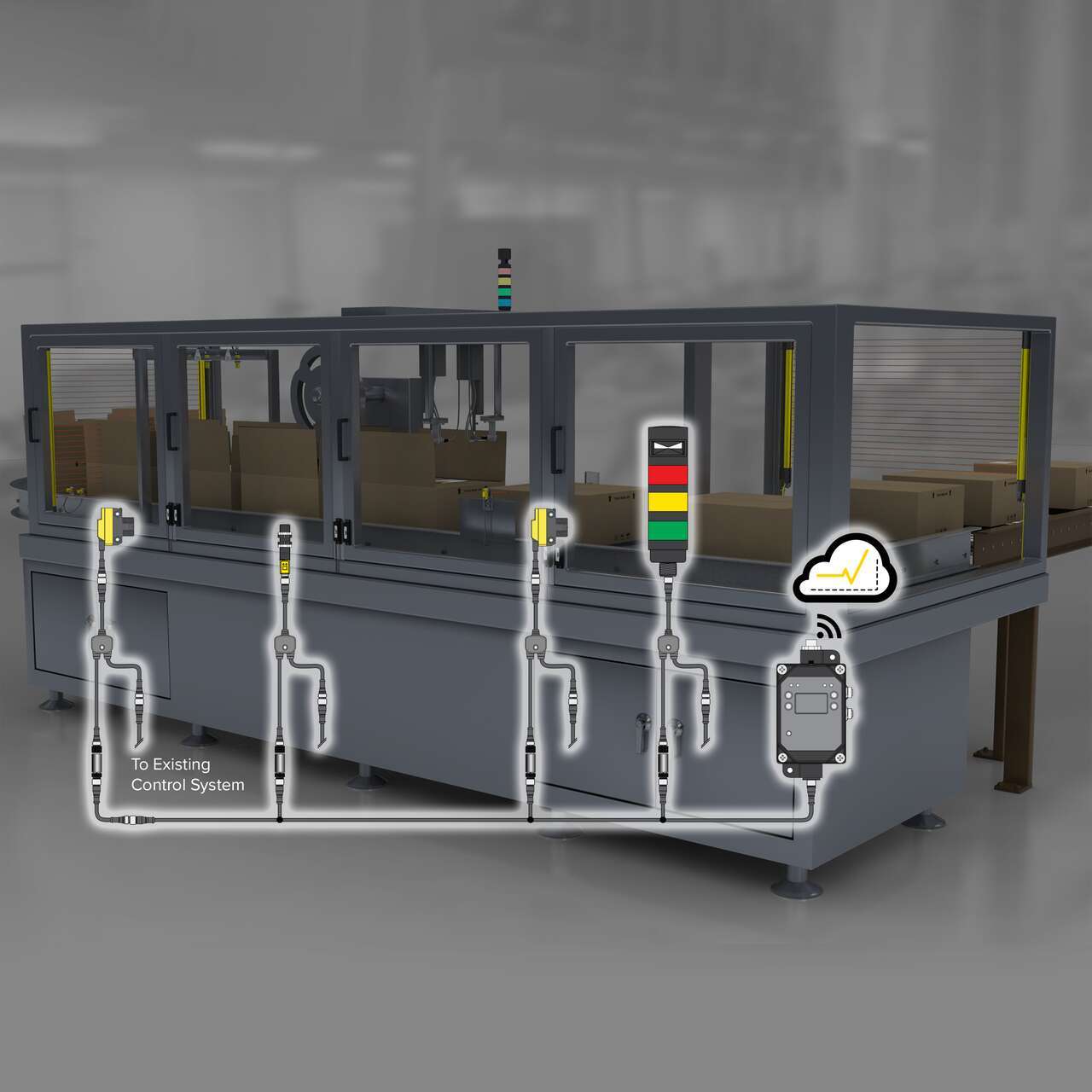

Snap Signal is designed to be a brand-agnostic, overlay-architecture technology, meaning that there’s no need to replace existing process assets or even older sensors. Snap Signal converters can be installed to branch off from existing sensors and send serial data to a Banner DXMR90 Industrial Controller. This controller combines converted signals—potentially from an entire production environment—into a single data stream that can be processed locally with an industrial ethernet protocol or in cloud networks, including Banner’s own Cloud Data Services. Then, users can monitor equipment performance data from anywhere with online visualization tools, and receive 24/7 notifications about any process critical asset operating below customizable thresholds.

Fill Out This Form to Speak With An Engineer to Learn More

See Other Applications on How Snap Signal Unlocks Your Factory's True Potential

-

-

Discrete Sensors to the Cloud

-

Pressure Sensor Data for Immediate Insights

-

Temperature Data to the Cloud

-

Monitor Hydraulic Power Units

-

Condition Monitoring of Dust Collection System

-

Monitor Tank Level Remotely in a Snap

-

Increase Productivity on an Injection Molding Machine

-

Measure Throughput and OEE on a Case Sealer