-

Products

-

Sensors

-

Ultrasonic Sensors

-

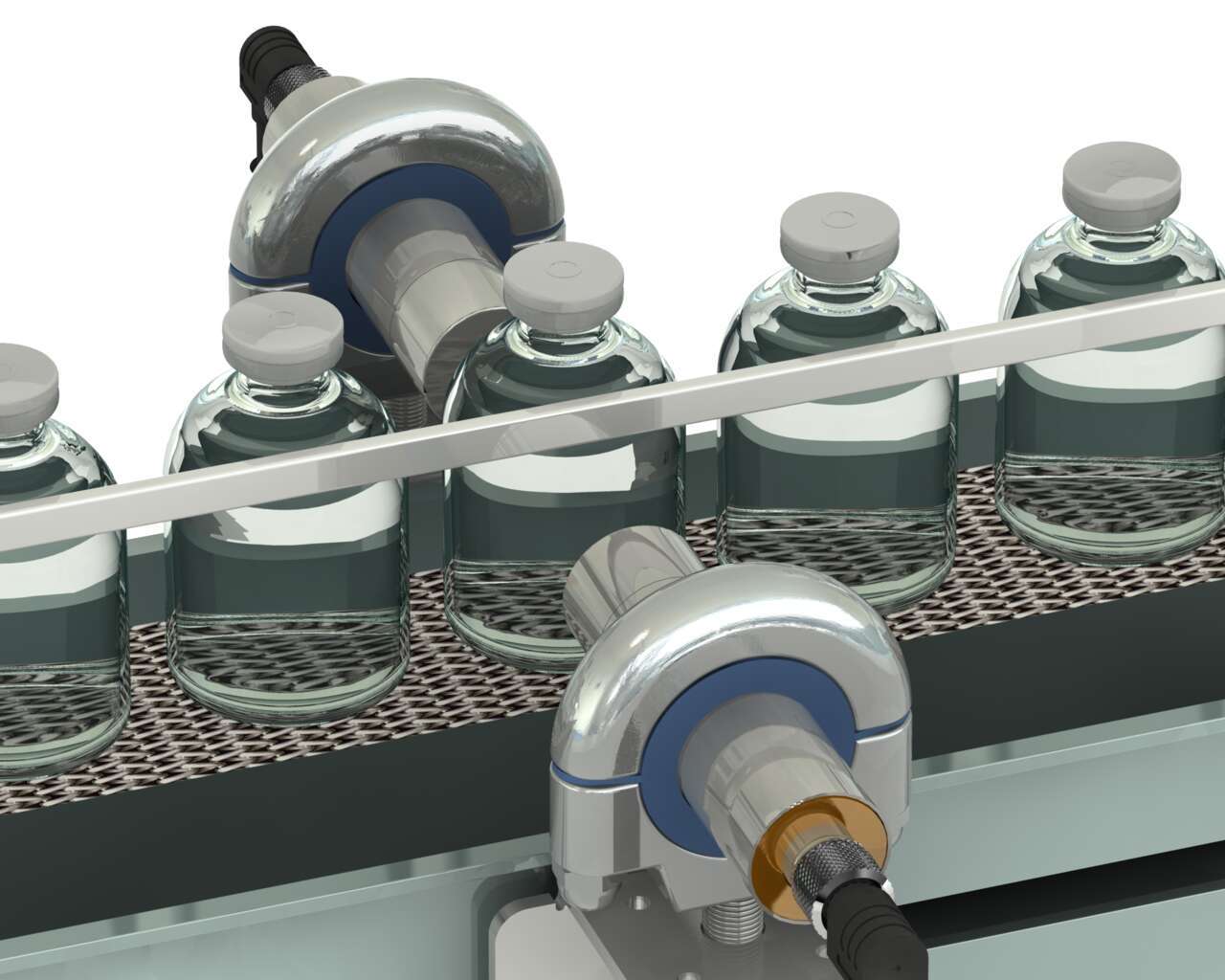

M25U Stainless Steel IP69K Ultrasonic Sensor

Stainless Steel IP69K

Waterproof, stainless steel, ultrasonic sensors were purpose-built to deliver flawless operation in food processing and other sanitary industries.

- Dual range/dual speed opposed mode ultrasonic sensors ideal for sensing clear objects or materials

- Features smooth 316 series stainless steel construction to withstand the toughest sanitary environments

- Rated IP69K, IEC IP67 (NEMA 6) with fully encapsulated electronics

- Wide standard operating temperature range of -20° to +70°C (-4° to +158° F)

- Withstands high-temperature sprays of up 80°C and 1500 psi occurring every few hours

- Constructed of FDA approved materials cleans easily with no threads, gaps or seams to trap debris

- Highly immune to ambient sonic and electrical noise

- Available in models with IO-Link communication for simplified wiring, installation, preventative maintenance, and sensor backup

- Select between mechanical and electronic adjustable field

- Opposed-mode models now available with superior light immunity, crosstalk avoidance, and IO-Link communication

M25U Stainless Steel IP69K Ultrasonic Sensor

Applications

-

Sensor solutions to detect bottle types vary in size, shape, color, translucence, and material. Equipment is regularly exposed to harsh washdown.

-

Sensor solutions to detect bottle types vary by size, shape, color, contours, and translucence on a rinser where equipment is regularly exposed to washdowns.

-

Sensor solutions to detect glass vials filled with transparent liquid in an aseptic, stainless steel environment with rounded bottles.

-

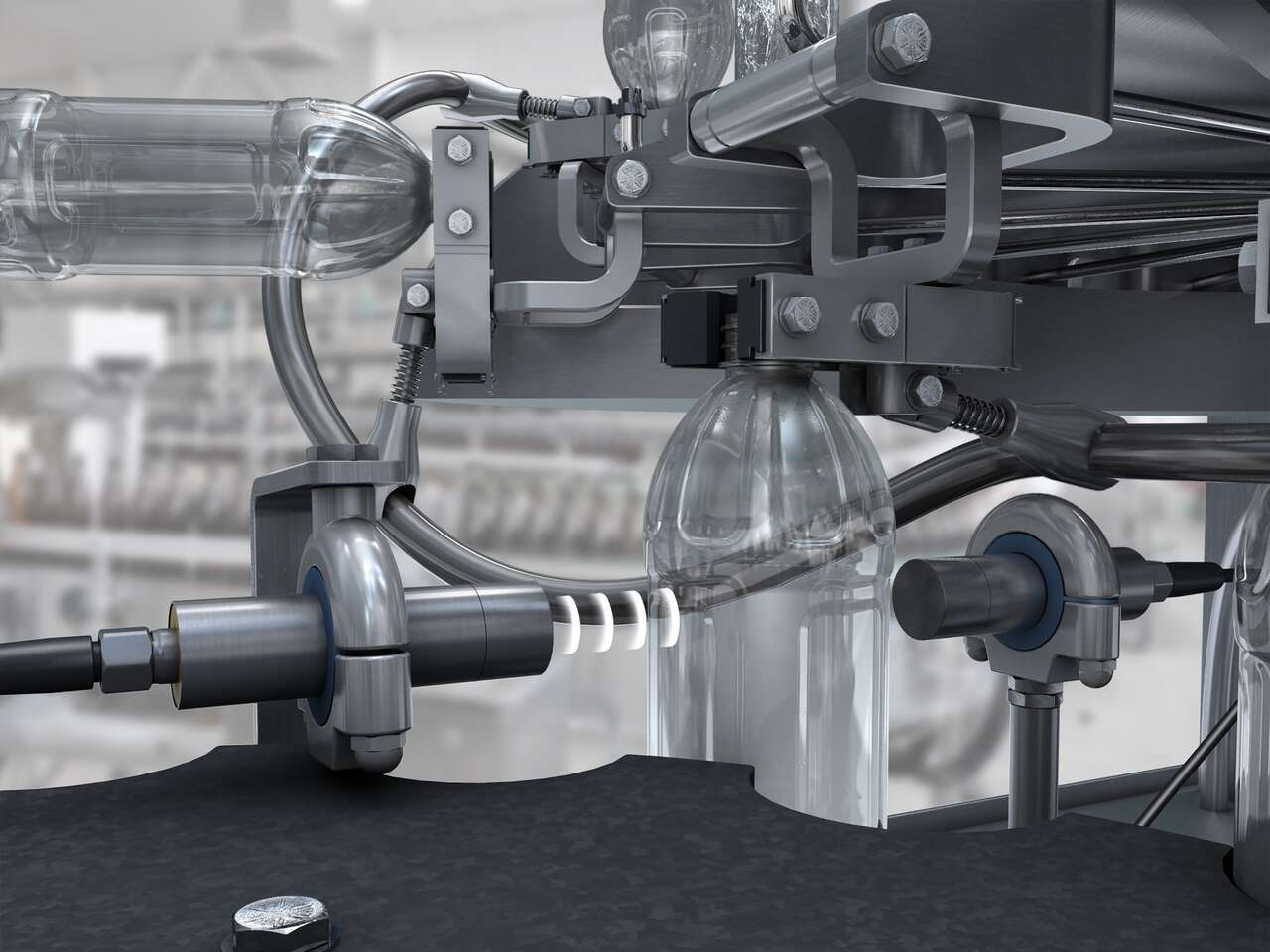

Clear Container Detection in a Clean-in-Place Rotary Filler

Sensor solutions to detect bottle types vary in size, shape, color, translucence, and material. Equipment is regularly exposed to harsh washdown.

-

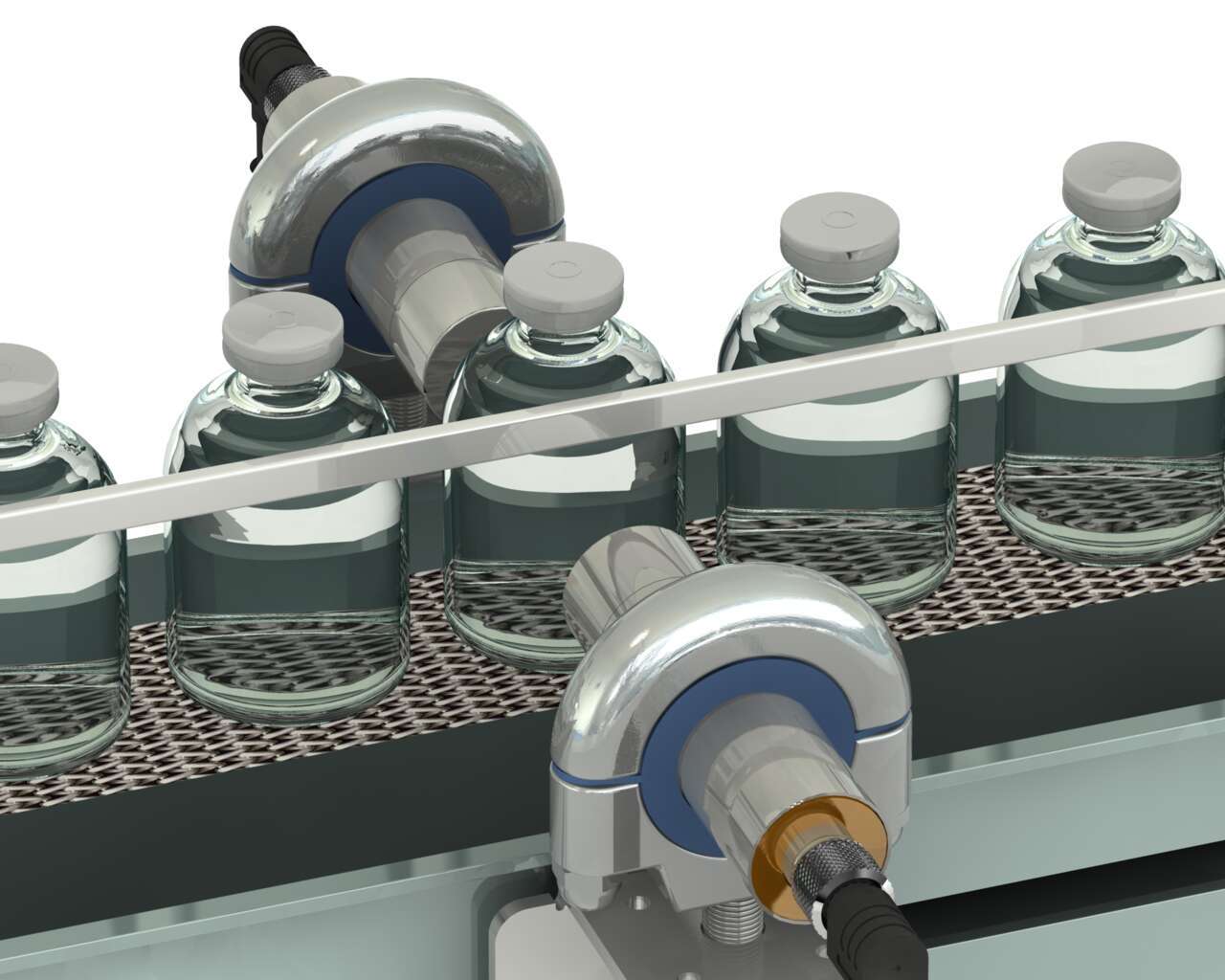

Hygienic Sensor Detects Variety of Bottle Types on a Rinser

Sensor solutions to detect bottle types vary by size, shape, color, contours, and translucence on a rinser where equipment is regularly exposed to washdowns.

-

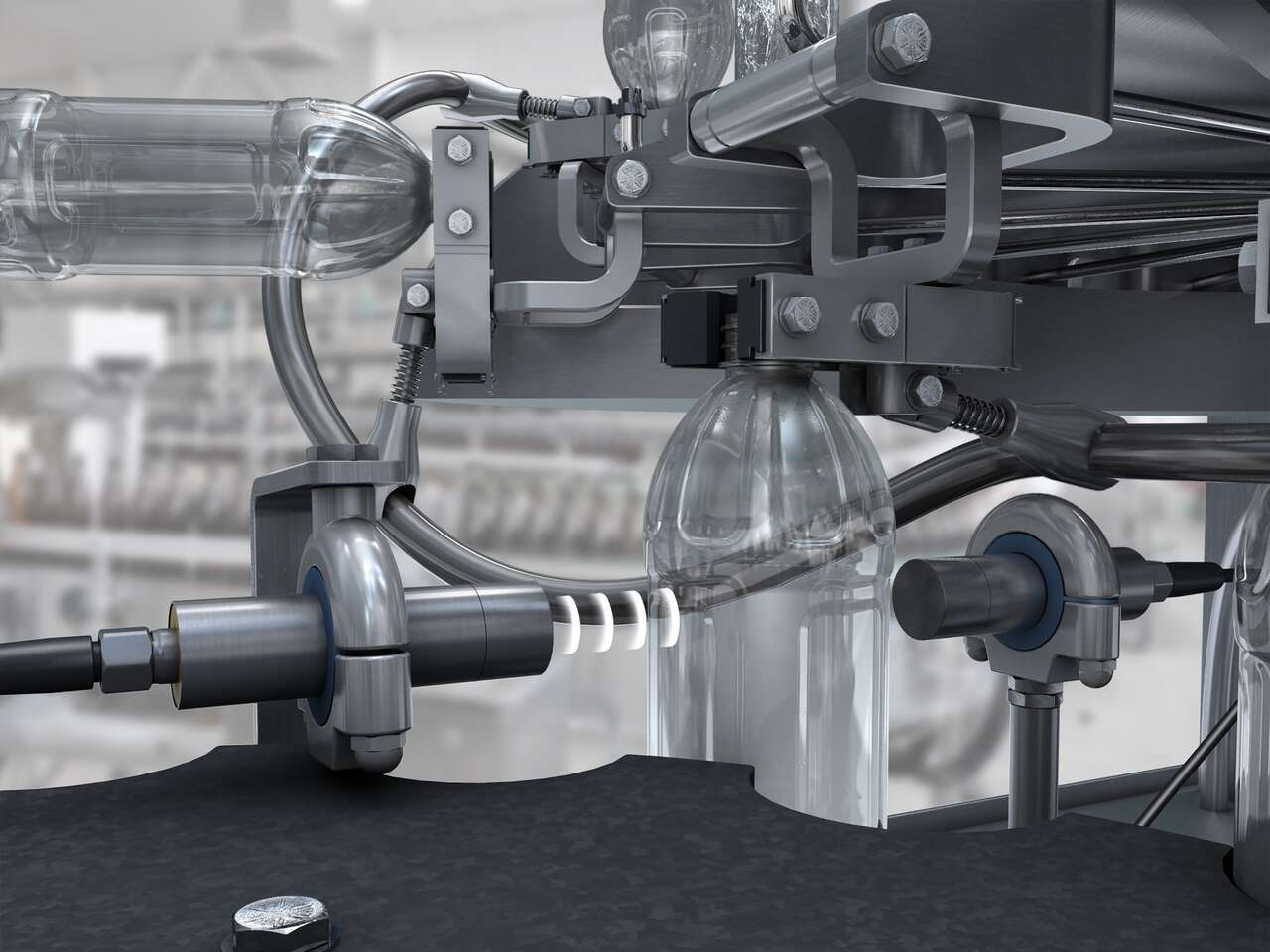

Detecting Clear Pharmaceutical Vials Filled With Liquid

Sensor solutions to detect glass vials filled with transparent liquid in an aseptic, stainless steel environment with rounded bottles.

Incomplete Checkout

Share Your Checkout Experience

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

Downloads

English Documents

Have a Technical Question?

Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.