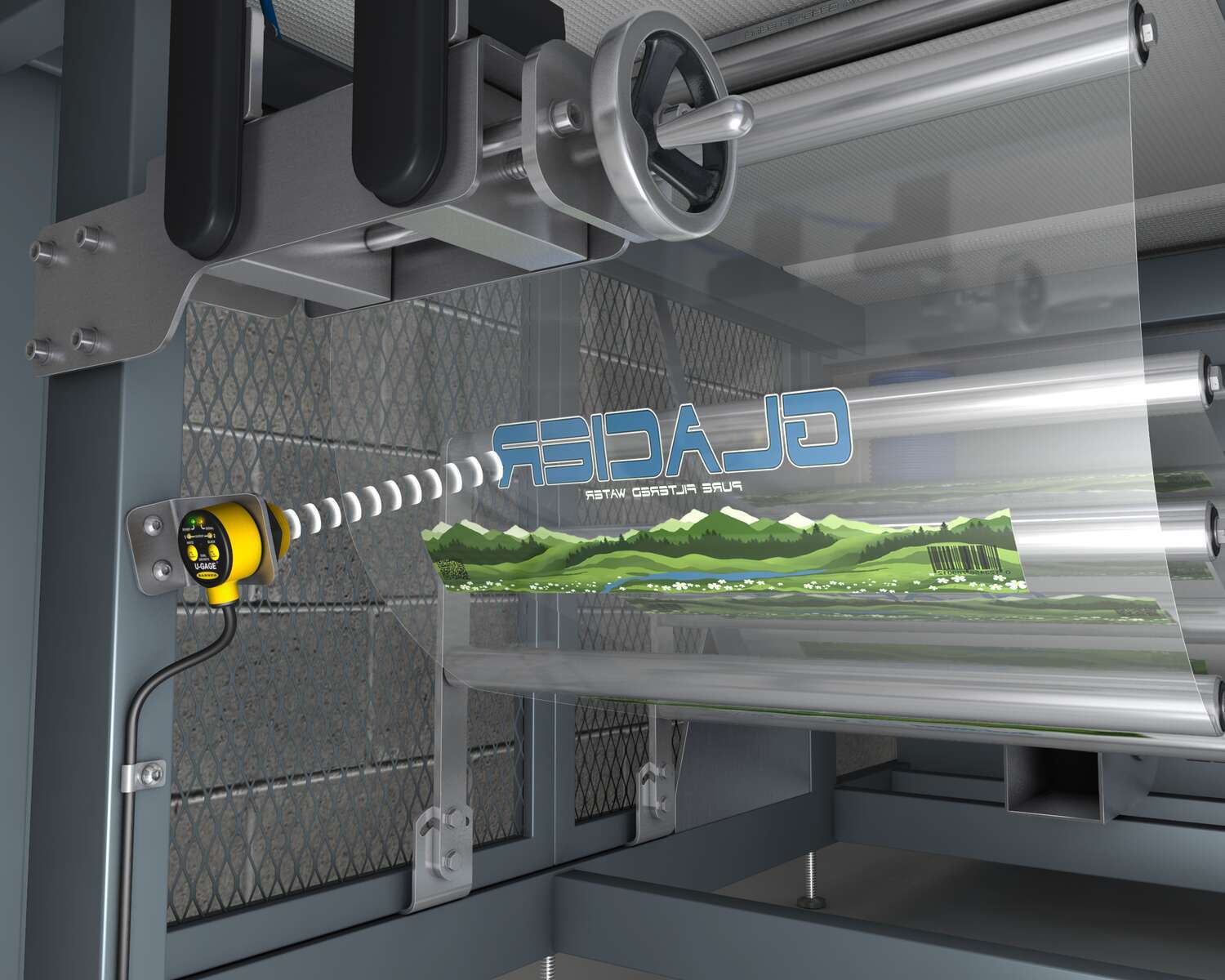

2 Meter Range Ultrasonic Sensor

- Offers choice of dual-discrete or analog/discrete output

- Available with range of 150 mm to 1 m or 300 mm to 2 m, depending on response time

- Offers dual-discrete models for ON/OFF switching or pump/level control

- Available with analog output for applications requiring a continuous current or voltage output

- Features independently programmable outputs

- Housed in T-style right-angle housing with 30 mm threaded nose

- Available in chemically resistant models with a Teflon coating to protect the transducer

- Simplifies setup with push-button TEACH programming of custom sensing window

- Allows remote programming with an external switch, computer or controller for added security and convenience

- Provides digital filtering for exceptional electrical and noise immunity

Recommended Latest Technology: T30UX Series

Temp Compensation Ultrasonic Sensor

- Offers choice of user-selectable NPN or PNP discrete or 0-10V dc or 4-20 mA analog output

- Available with range of 100 mm to 1 m, 200 mm to 2 m, or 300 mm to 3 m

- Delivers high-accuracy performance with built-in temperature compensation across a wide range of ambient temperatures

Downloads

Technical Literature

Date

Type

Size

Date

Type

Size

Date

Type

Size

Date

Type

Size

Software

Date

Type

Size

Brochures & Catalogs

Date

Type

Size

Product Selection