-

Products

-

Industrial Wireless

-

I/O Radios

-

PM Series - Wire Replacement

Wireless I/O Data Radios

An I/O Radio network that combines long range line-of-sight coverage with ease of deployment and use.

The PM Series provides a flexible network that easily sets up without software. Setting up a basic point-to-point network is as easy as pairing a cell phone to a headset. You can replace cables and extend the range of digital and analog signals with minimal effort.

- No software needed

- Menu-driven LCD user interface

- Choose from two I/O configurations

- Select from multiple I/O maps

- One gateway is preconfigured to support up to two (PM2) or six (PM8) nodes

- IP67 rated housing for demanding environments

PM Series - Wire Replacement

Applications

-

During normal operation, operators load a welding machine with the frame components to be welded. The customer needed accurate machine run time data to determine why production goals were not being met.

-

The customer needs a solution that can increase the forklift operator's response time by putting indicators on the forklift's dashboard and can also allow the forklift operator to acknowledge the request, which eliminates redundant part deliveries by multiple operators.

-

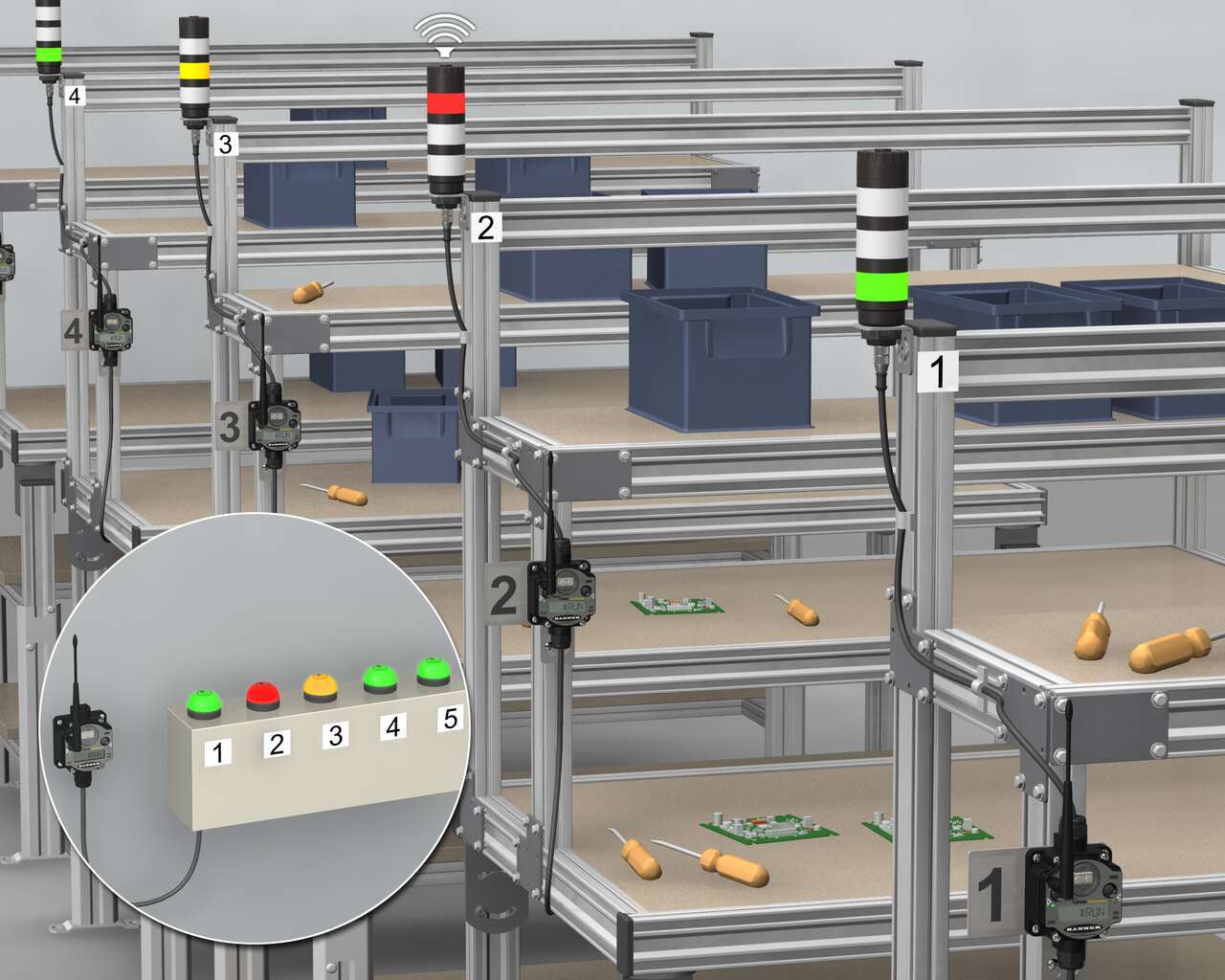

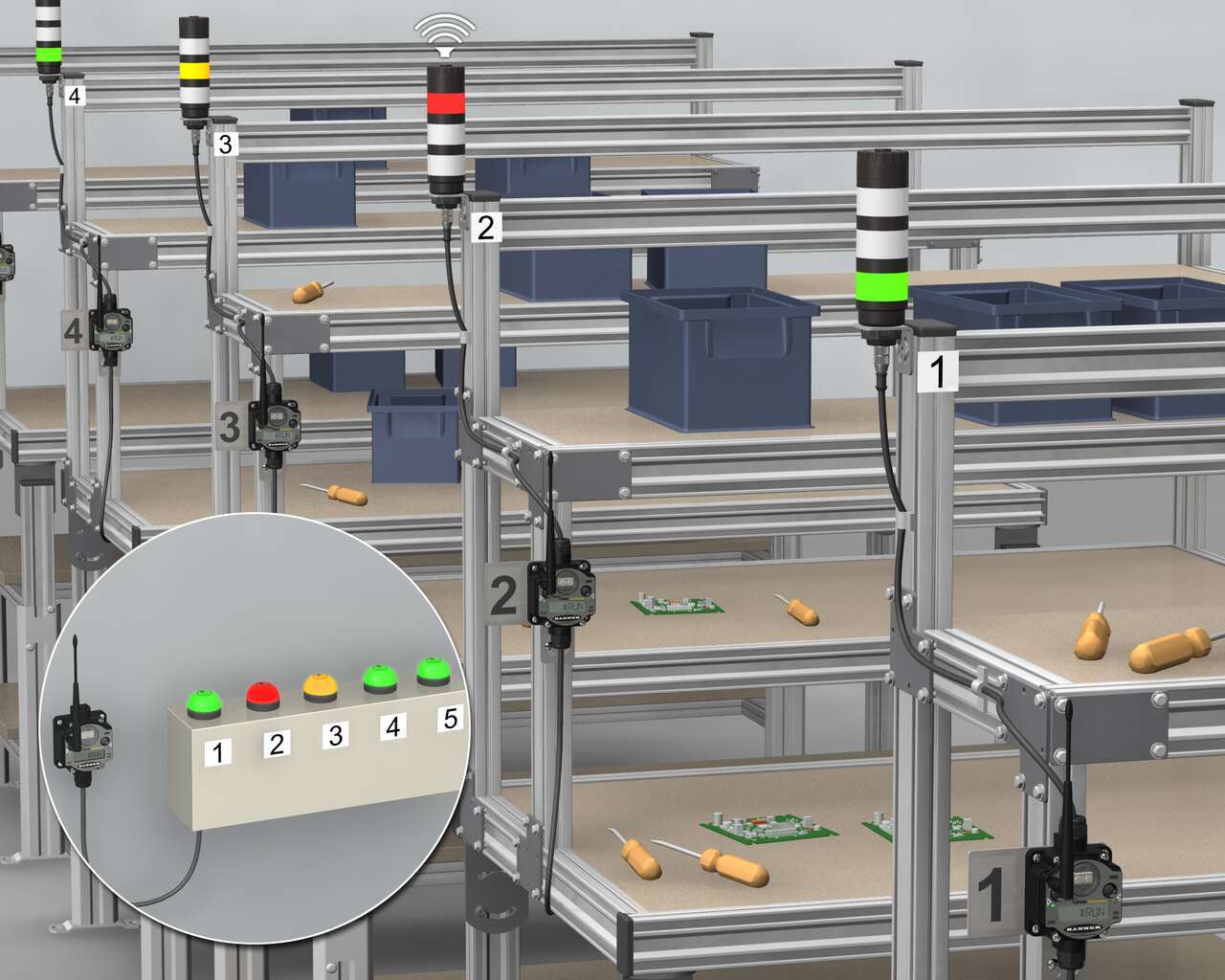

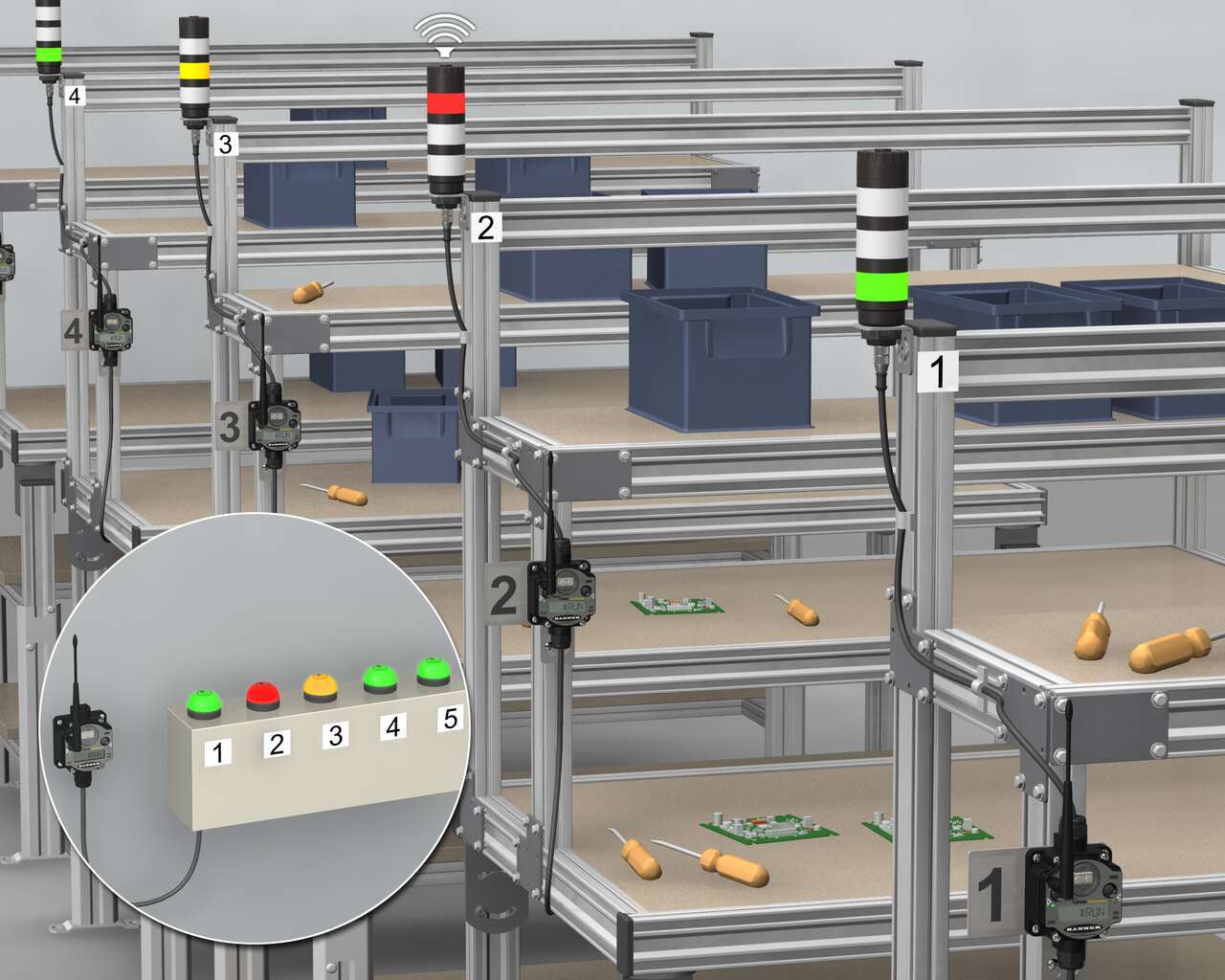

To improve efficiency, assemblers at work stations need a way to call for parts and service that doesn’t involve them leaving their work stations. Getting parts more quickly would improve production efficiency, and using a system of remote indicators would let the supervisors to see the status of each work station, allowing the supervisors to fix production problems quickly and to collect production metrics.

-

With high-quality LED lights and multiple colors in one device, Banner's multi-segment audibleTL50, combined with the K50 Touch and PM8 wireless system result in efficient call for part processes. To begin, Banner’s K50 ergonomic touch buttons are installed in a supervisor station and numbered according to their corresponding PML8 Wireless Nodes, which are installed at individual workstations along with an audible tower light.

-

Remote Monitoring Calculates Machine Run Time

During normal operation, operators load a welding machine with the frame components to be welded. The customer needed accurate machine run time data to determine why production goals were not being met.

-

Call for Parts at a Furniture Manufacturer

The customer needs a solution that can increase the forklift operator's response time by putting indicators on the forklift's dashboard and can also allow the forklift operator to acknowledge the request, which eliminates redundant part deliveries by multiple operators.

-

Streamlining Call for Parts or Service

To improve efficiency, assemblers at work stations need a way to call for parts and service that doesn’t involve them leaving their work stations. Getting parts more quickly would improve production efficiency, and using a system of remote indicators would let the supervisors to see the status of each work station, allowing the supervisors to fix production problems quickly and to collect production metrics.

-

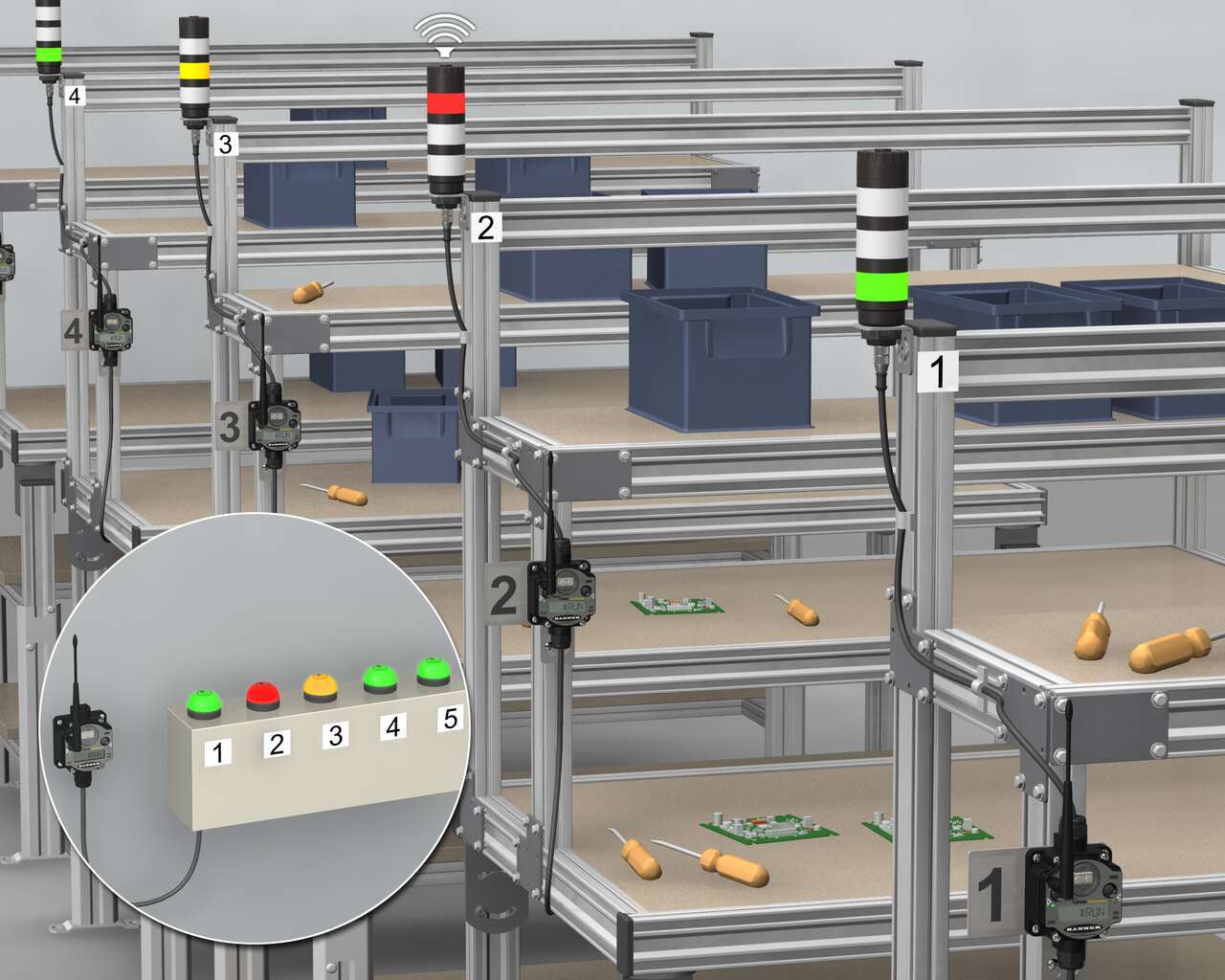

Wireless Call for Parts

With high-quality LED lights and multiple colors in one device, Banner's multi-segment audibleTL50, combined with the K50 Touch and PM8 wireless system result in efficient call for part processes. To begin, Banner’s K50 ergonomic touch buttons are installed in a supervisor station and numbered according to their corresponding PML8 Wireless Nodes, which are installed at individual workstations along with an audible tower light.

Incomplete Checkout

Share Your Checkout Experience

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

Downloads

English Documents

Have a Technical Question?

Have a question about this product series? Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.