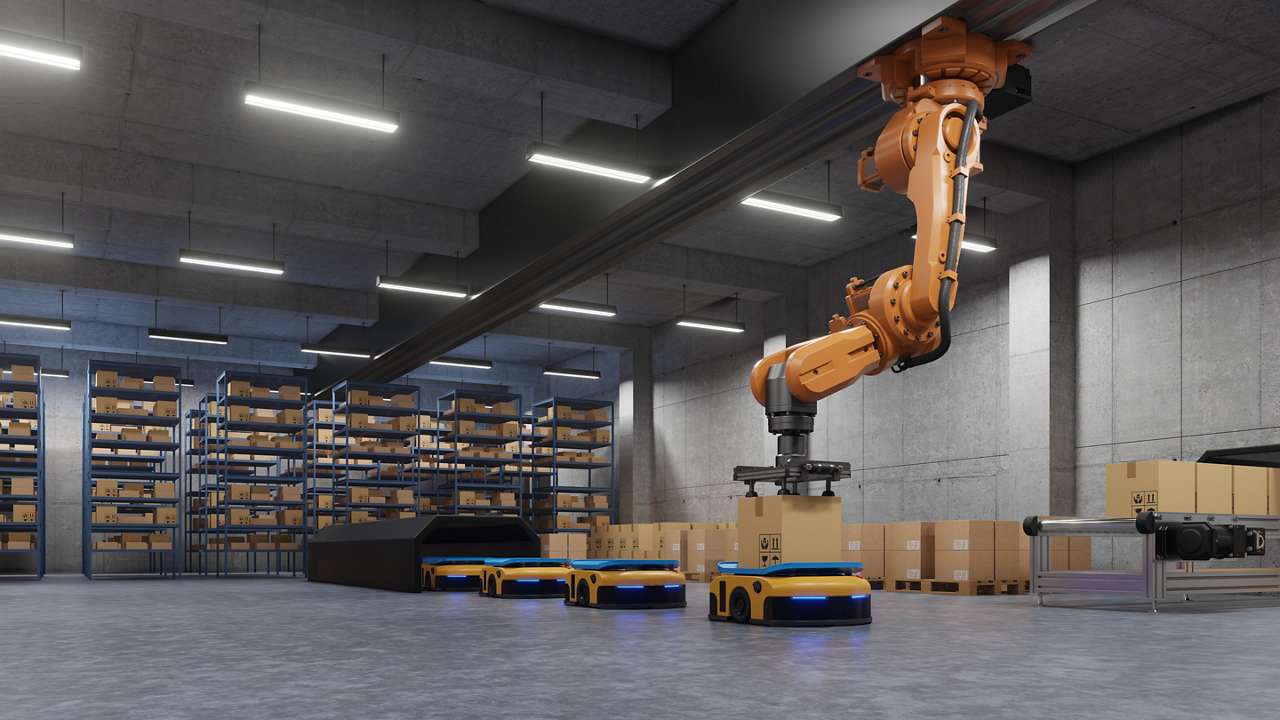

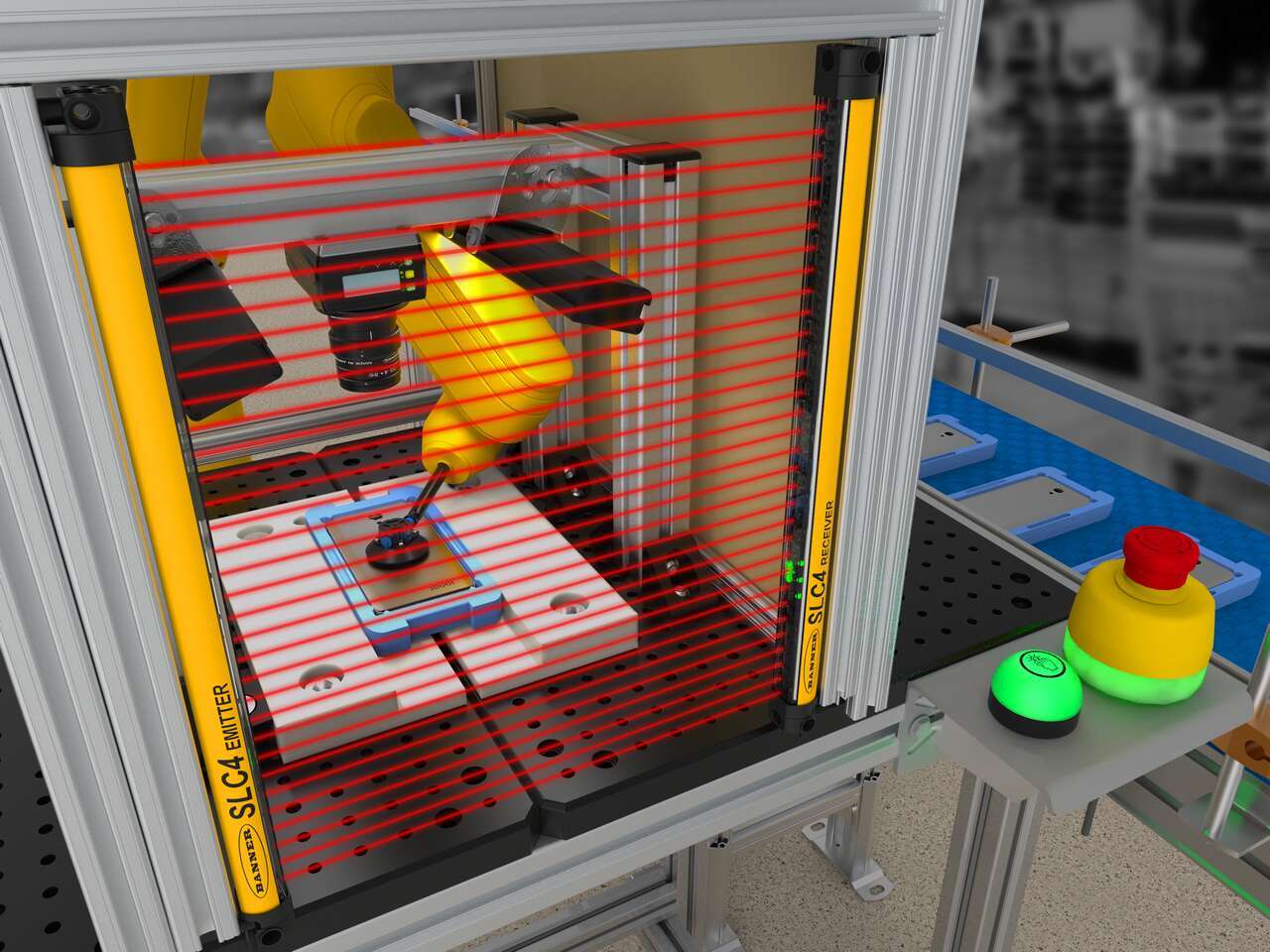

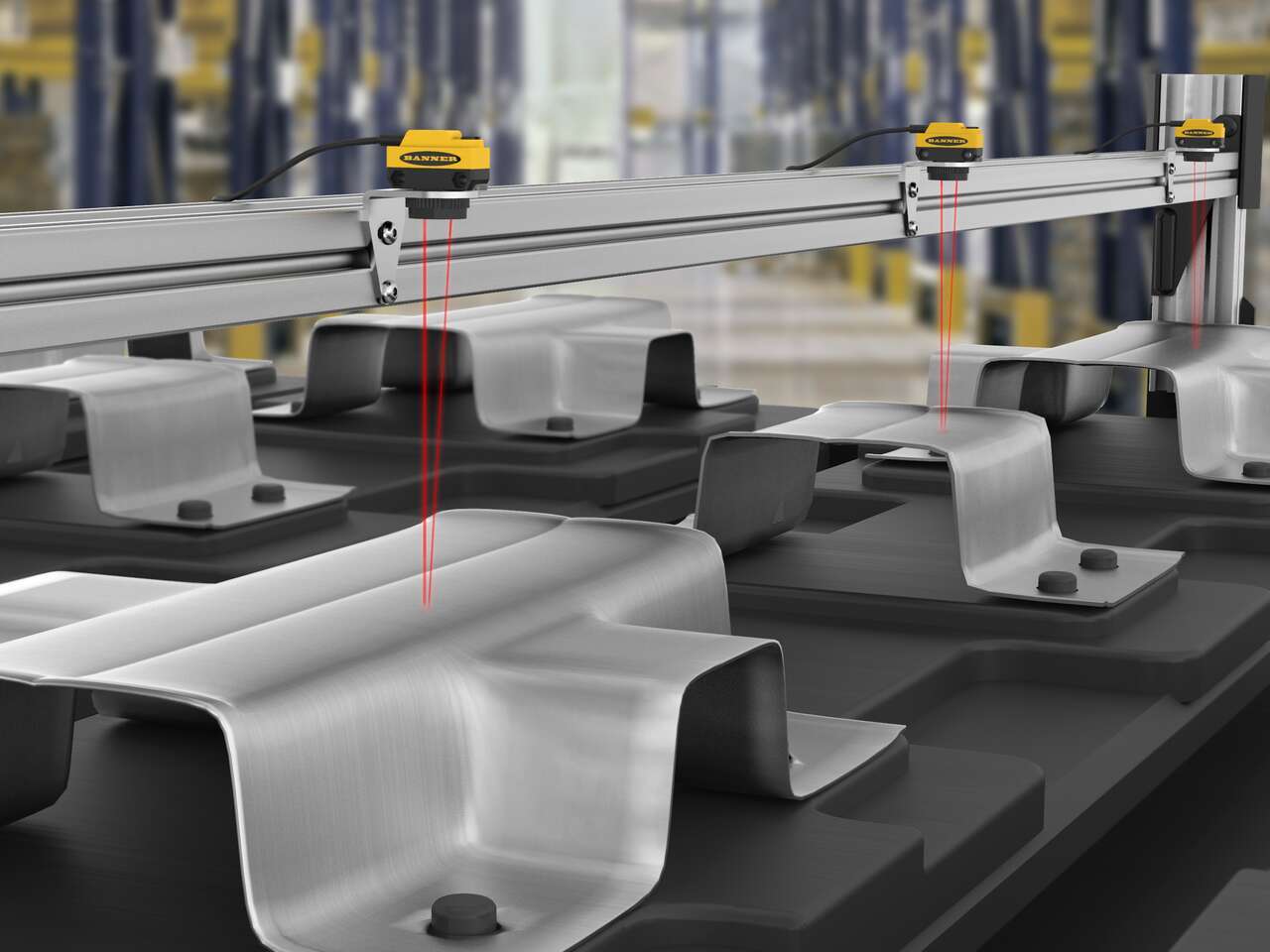

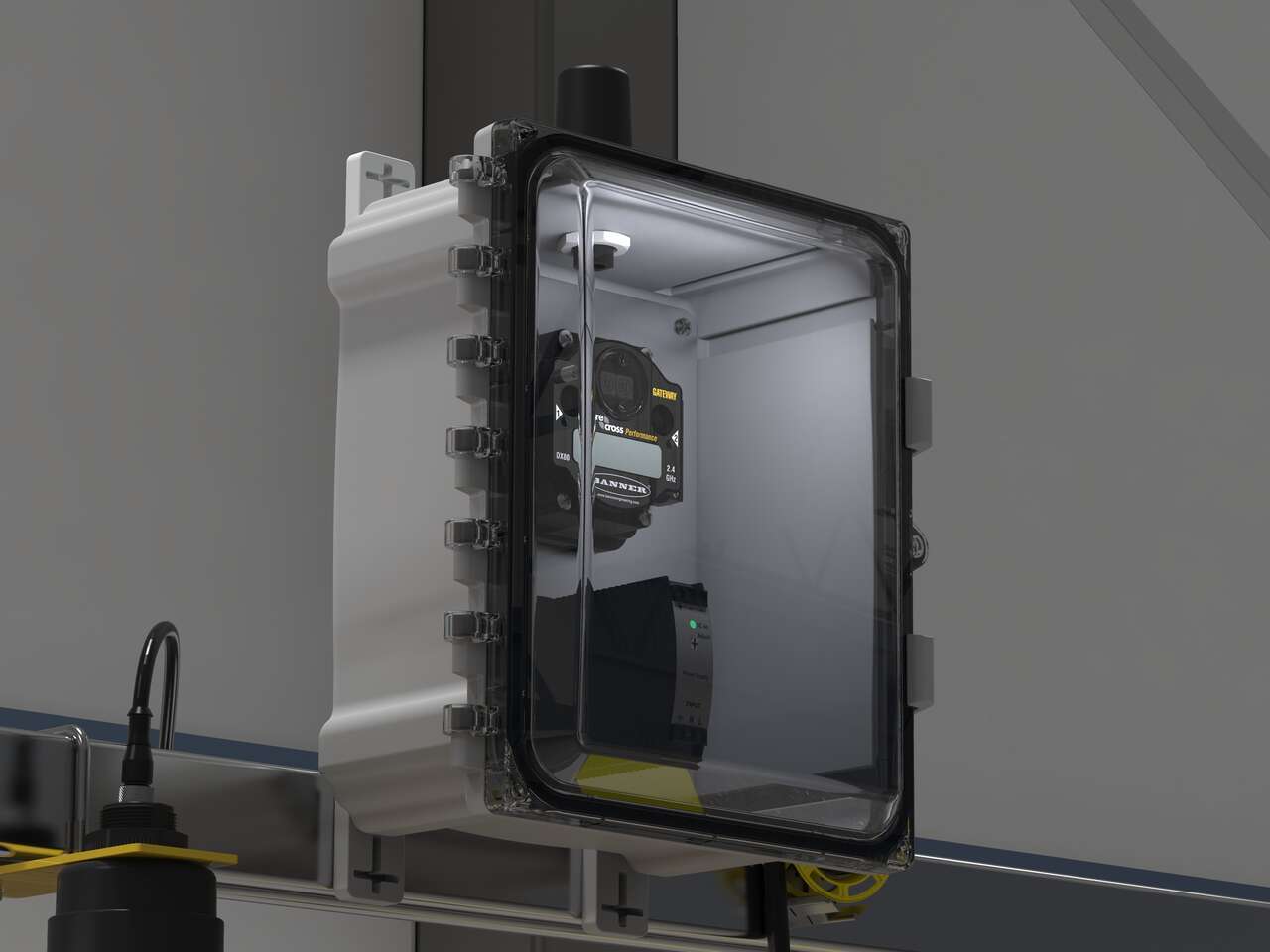

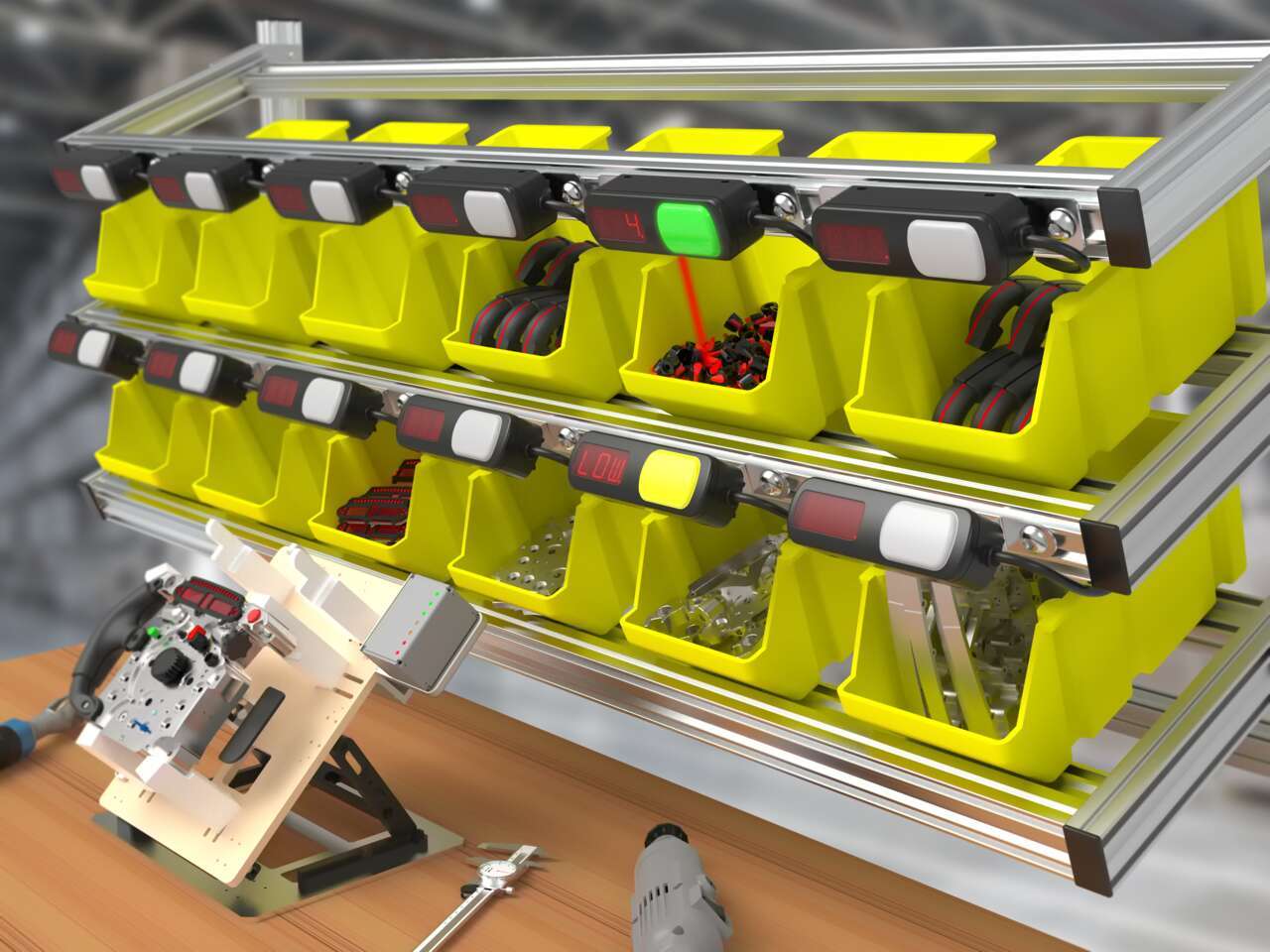

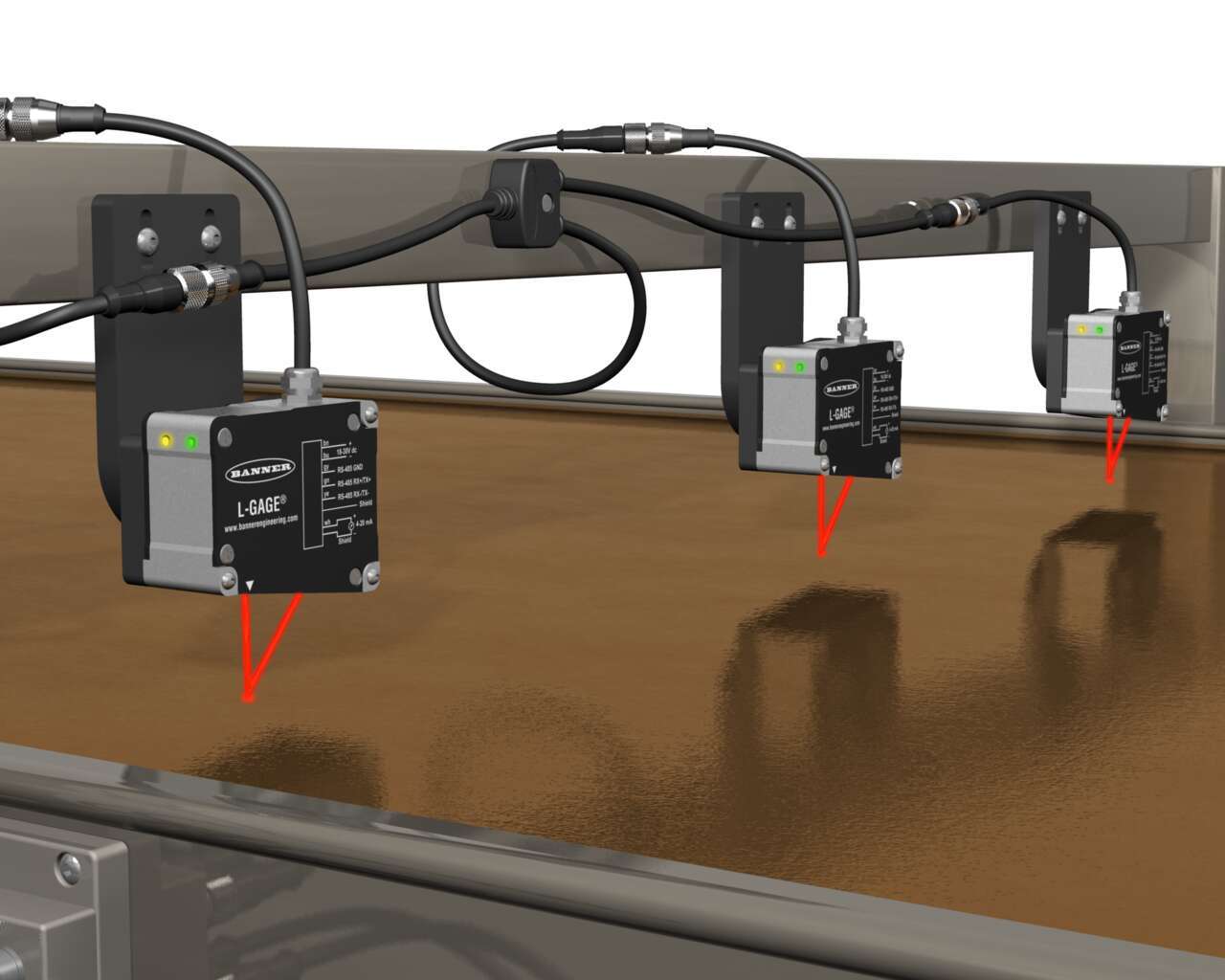

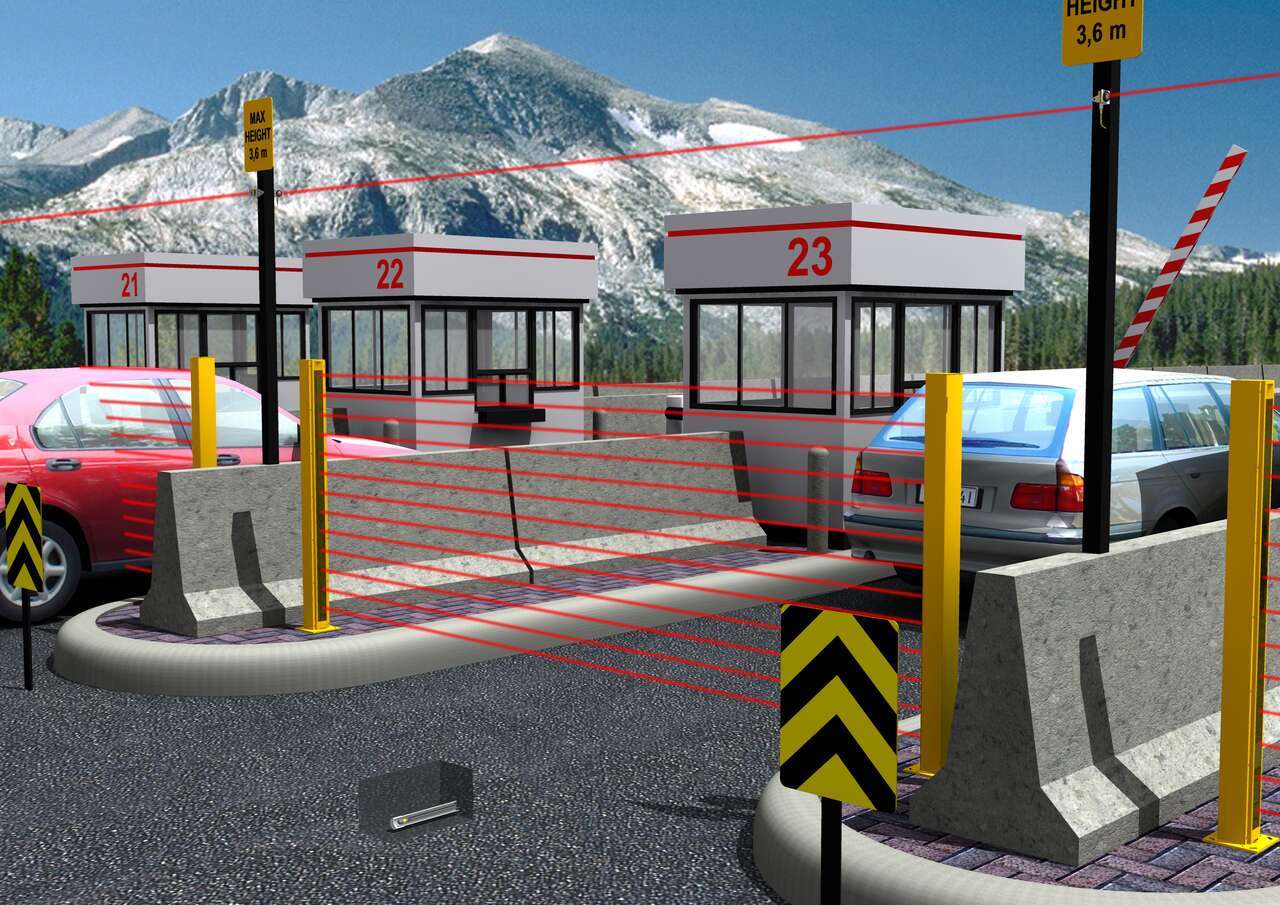

Applications

Solutions Designed for Challenging Applications

Every day, thousands of times a day, in locations all around the world, products from Banner Engineering are used to solve challenging problems and achieve automation goals. We work closely with our customers, partners and industry experts to analyze an application and identify the key products, features, and components necessary to solve it. The final product is a smart, cost-effective solution that satisfies customer requirements, performs at the highest levels, and reliably solves the application.