Improve Overall Equipment Effectiveness by Monitoring Production Input and Output

Application: Wireless sensors optimized for counting parts are used to monitor production efficiency and performance

Challenges: Adding monitoring capabilities to legacy equipment.

Collecting data from multiple points on a large production line.

Rewiring sensors to accommodate frequent product changeover.

Solution: Sure Cross® Q45 Wireless Sensors and a DXM Series Wireless Controller

Customer Benefits

Increased Uptime: System is configured to notify personnel via text or email if performance parameters are outside of user-defined levels, enabling a quick response and resolution of any issue.

Remote Monitoring: Personnel does not have to be at a deployment to gather data. Multiple deployments can be monitored at once from a convenient, network enabled location.

Versatile Deployments: Wireless, plug-and-play solution installs easily on existing equipment, simplifies line reconfiguration, and can be used in remote and hard-to-access locations where implementing a wired solution would be difficult, impractical, or cost prohibitive.

Background

Monitoring production inputs and outputs provides machine operators and managers with critical data about their processes and equipment and can help them identify and resolve problems on the production line more quickly.

Challenges

Acquiring and accessing production information, particularly on legacy equipment, can be difficult. Adding sensors and communication cabling can be time consuming and expensive and may require significant alterations to area infrastructure.

Solution

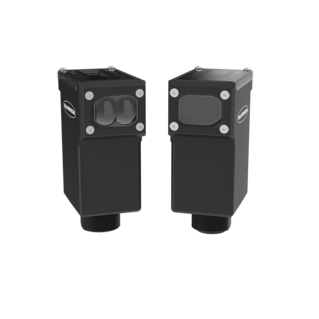

Installed at multiple strategic points along the production line, Sure Cross® Q45 wireless sensors count and totalize parts-in and parts-out from production equipment. Each Q45 houses a sensor, wireless radio, and long-life lithium batteries, for easy, plug-and-play installation. Diffuse and retroreflective models of the Q45 are preconfigured for part counting and totalizing, simplifying setup and enabling a rapid deployment. The sensor is easily configured to count and totalize up to 960 parts per minute using onboard DIP switches.

Information collected by the Q45 wireless sensor is transmitted at regular intervals over a secure, robust Sure Cross wireless network to a DXM Series wireless controller which uses the count rates to determine if equipment is running, running slow, stopped, jammed, or starved of parts. Whenever machine performance parameters are outside of user defined levels, the DXM will send an alert to staff via email or SMS text, ensuring a quick response and resolution to any issues on the line. Users can track parts per minute, monitor machine status, and gather metrics to calculate Over Equipment Effectiveness (OEE).

Features and Benefits

| Feature | Benefit |

|---|---|

| Feature Overall Equipment Effectiveness (OEE) Calculations | Benefit Calculates OEE actual vs. user defined ideal state answering: “How close is system to ideal state”. Instantaneous and averaged OEE parameters calculated including Availability (A), Performance (P), and Quality (Q). OEE = A × P × Q |

| Feature Part Counting | Benefit Use up to 8 pairs of battery-powered Wireless Q45 Nodes for part counting up to 960 parts/min |

| Feature Track Parts per Minute | Benefit Calculates parts/min rates for each counting pair of sensor nodes |

| Feature Monitor Machine State | Benefit By counting in/out - Determines machine states: Running, Slowed, Stopped, Jammed, or Starved based on part rates and user configurable settings. Track times and counts of error states. |

| Feature Extended Error Alerts | Benefit User configurable parameters to trigger alerts when error states are active for extended periods |

| Feature Alerts and Notifications | Benefit Generate SMS text and/or email alerts based on specific events |

| Feature Wireless Sensors | Benefit No additional control or power wires to install |

| Feature Scalability | Benefit Ability to easily add additional wireless nodes to monitor other operations |

| Feature IIoT / Cloud Monitoring | Benefit Push data to Cloud webserver or PLC (via LAN or cellular connection) for remote viewing, alerting, and logging |