-

All Applications

-

Other Applications

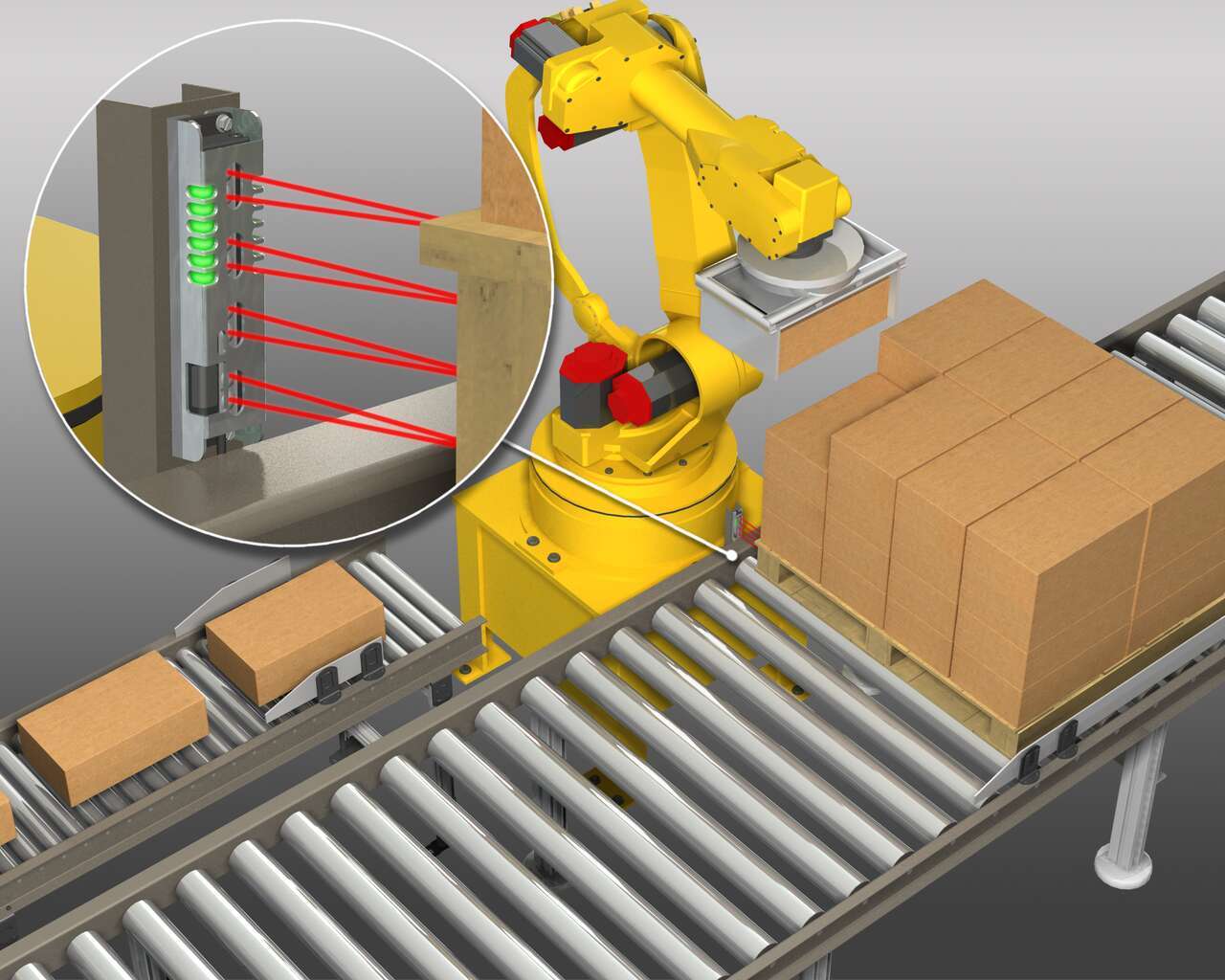

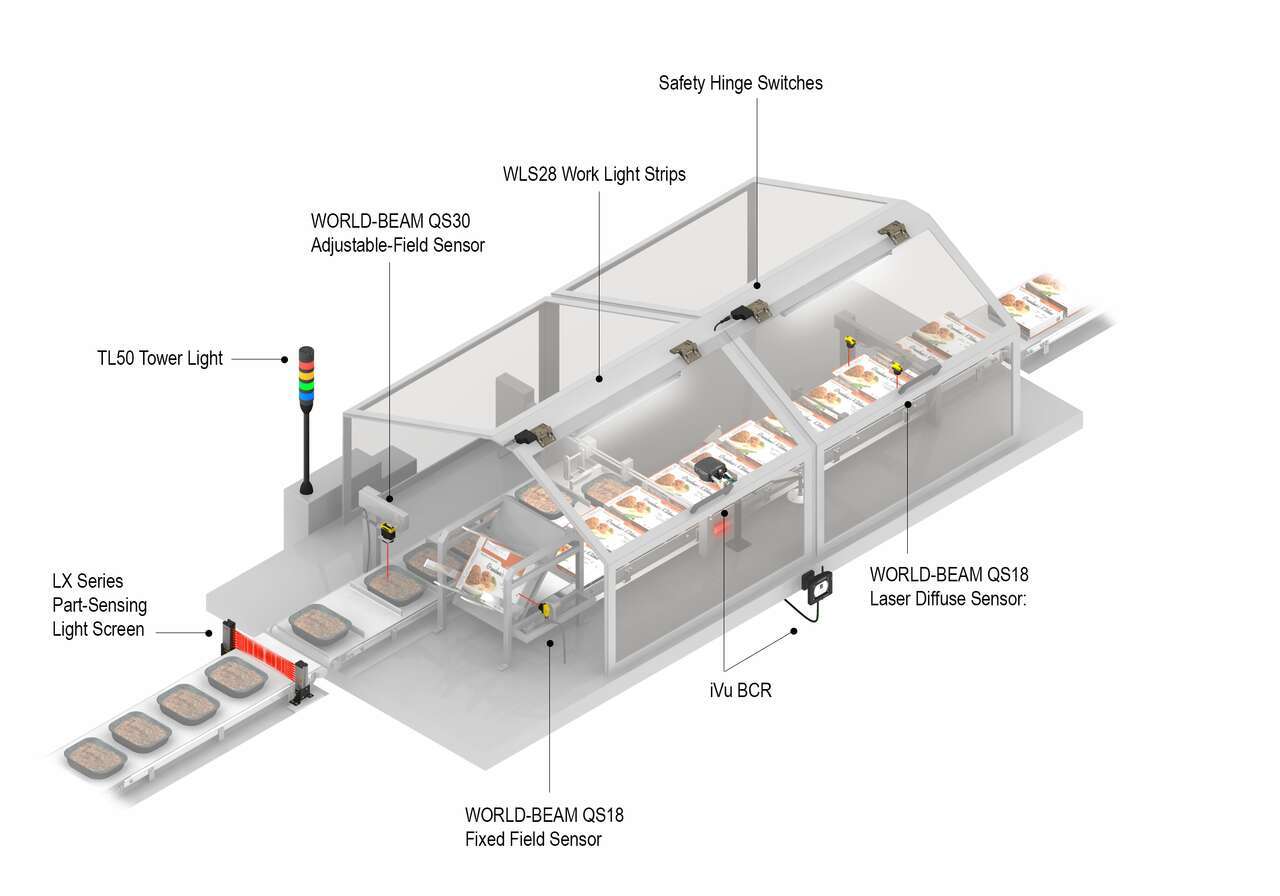

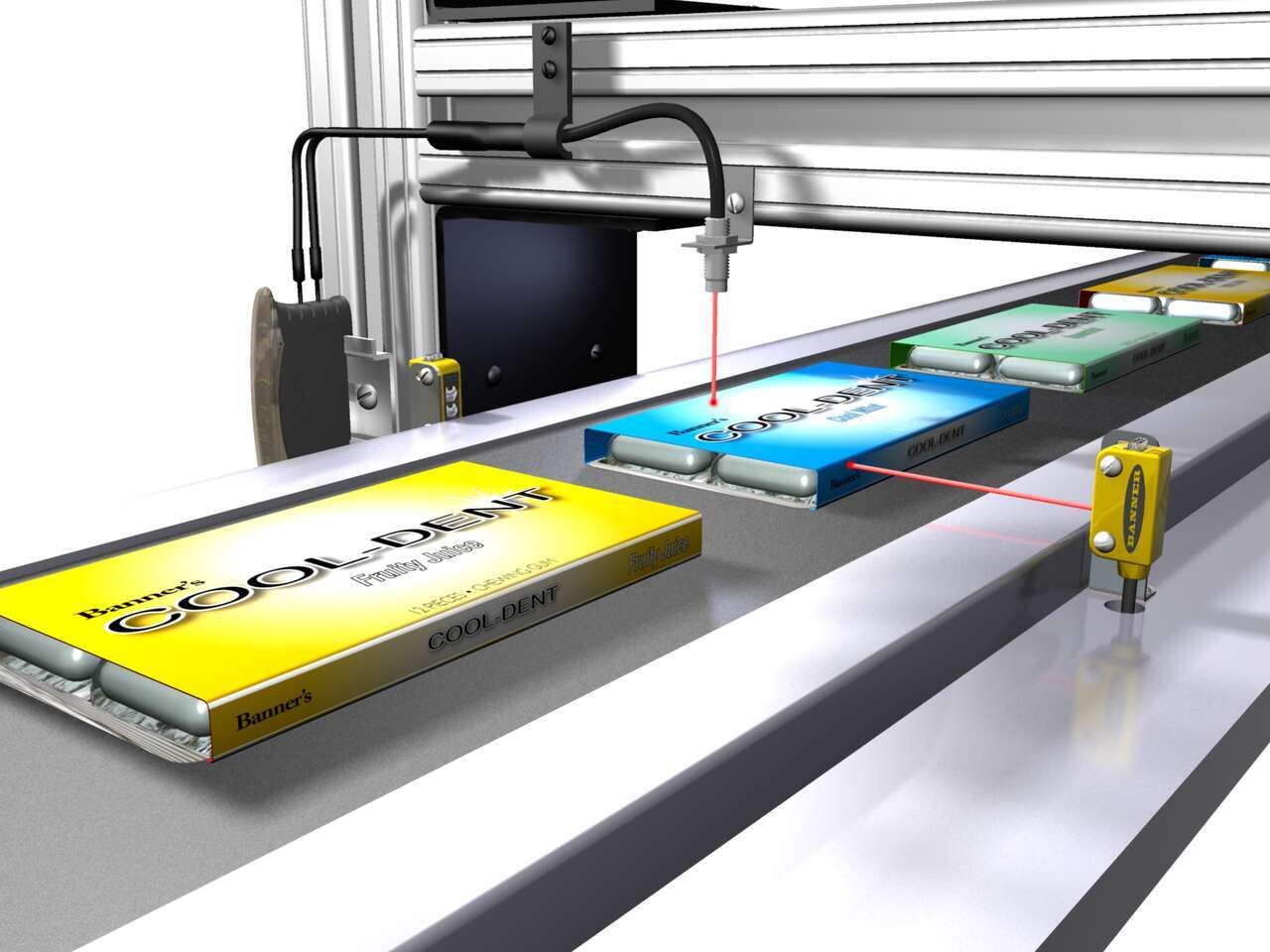

Solving Your Toughest Challenges

Other Applications

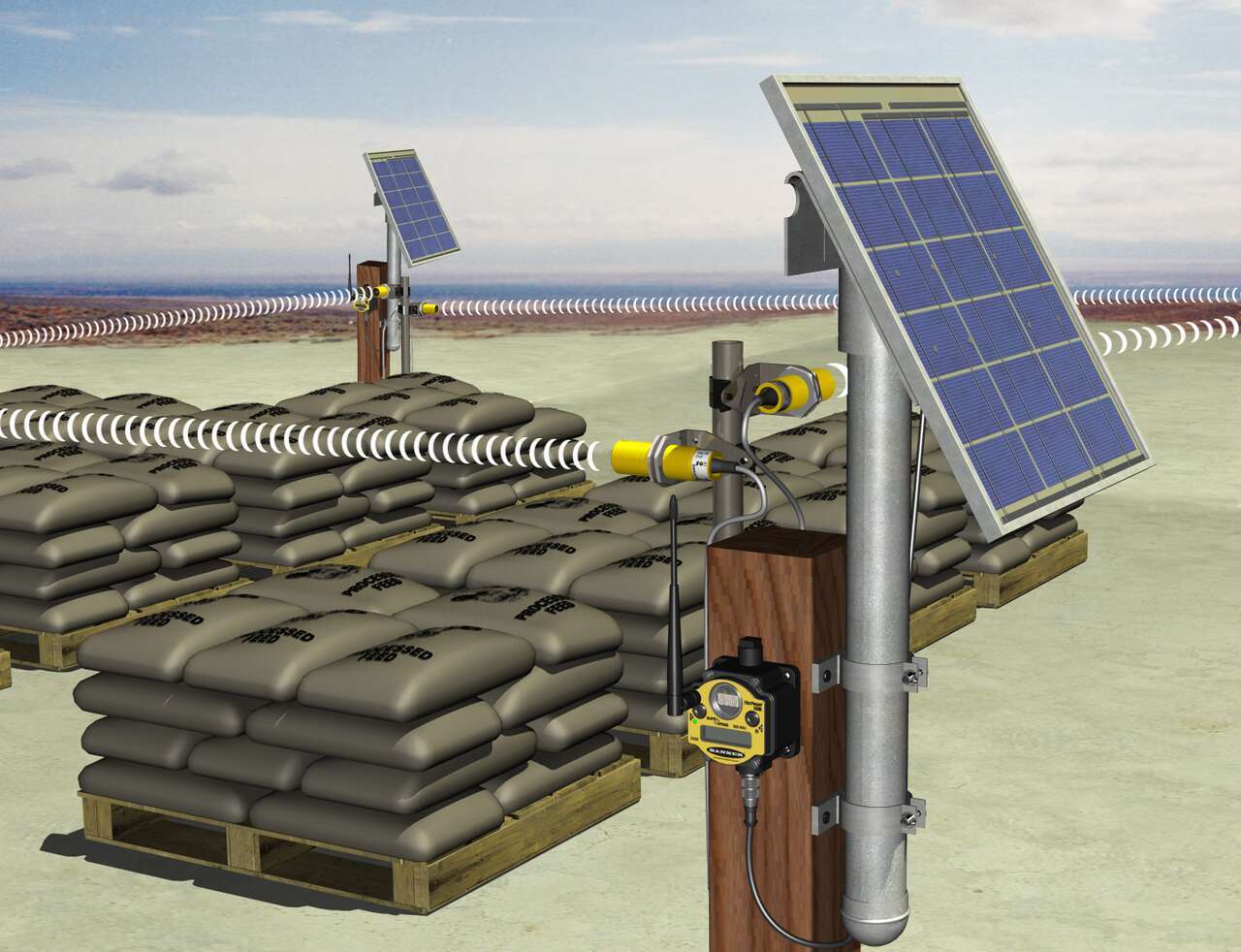

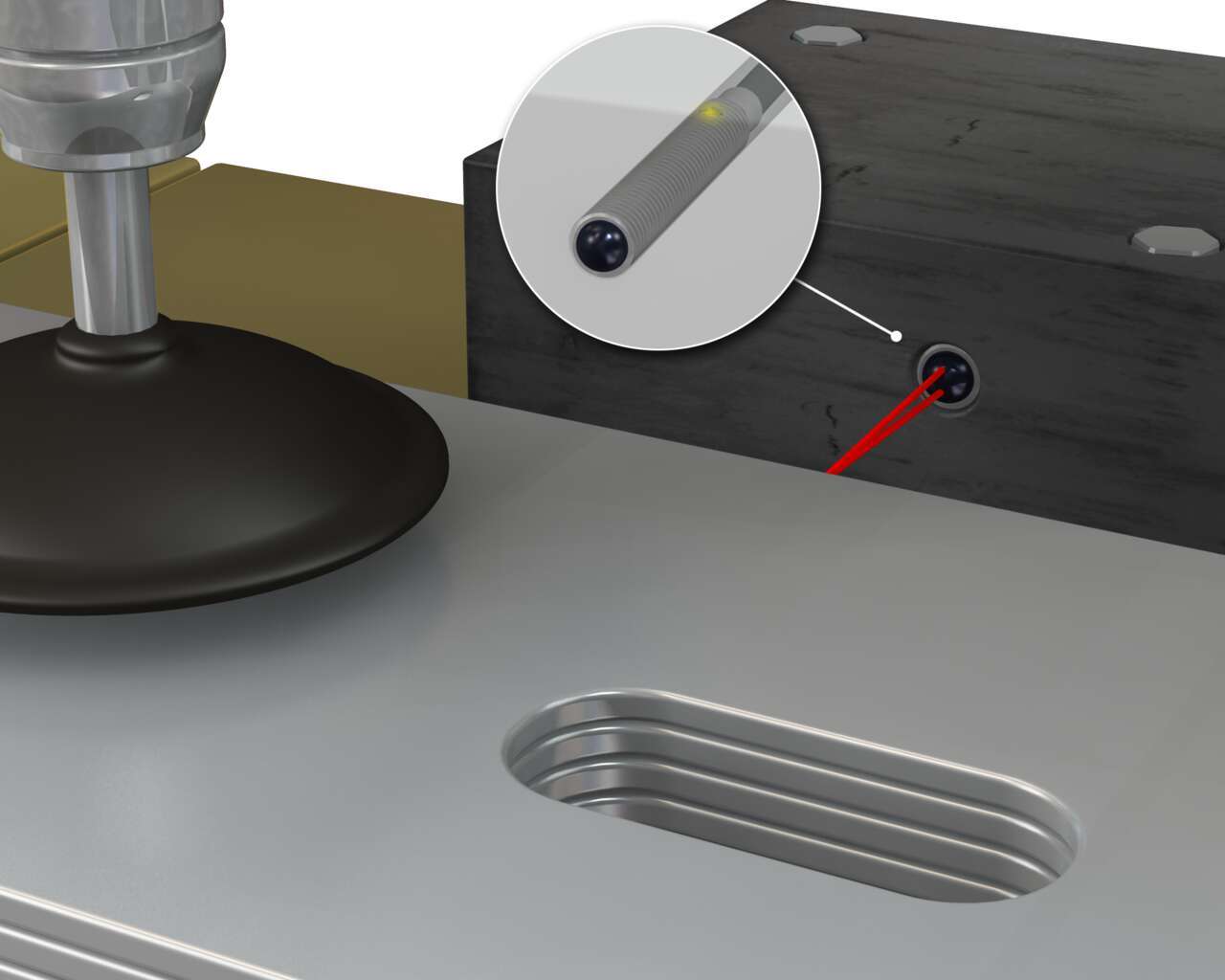

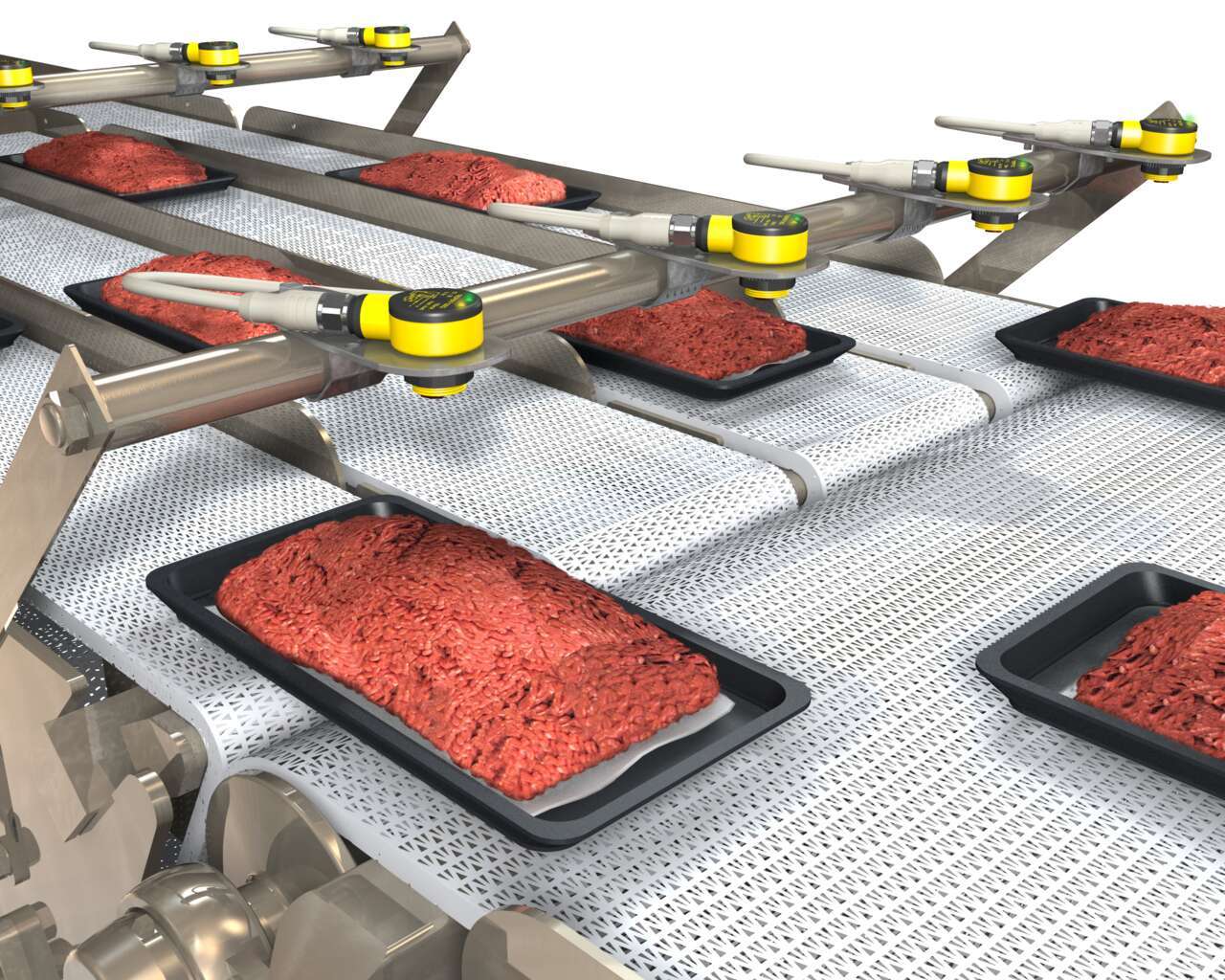

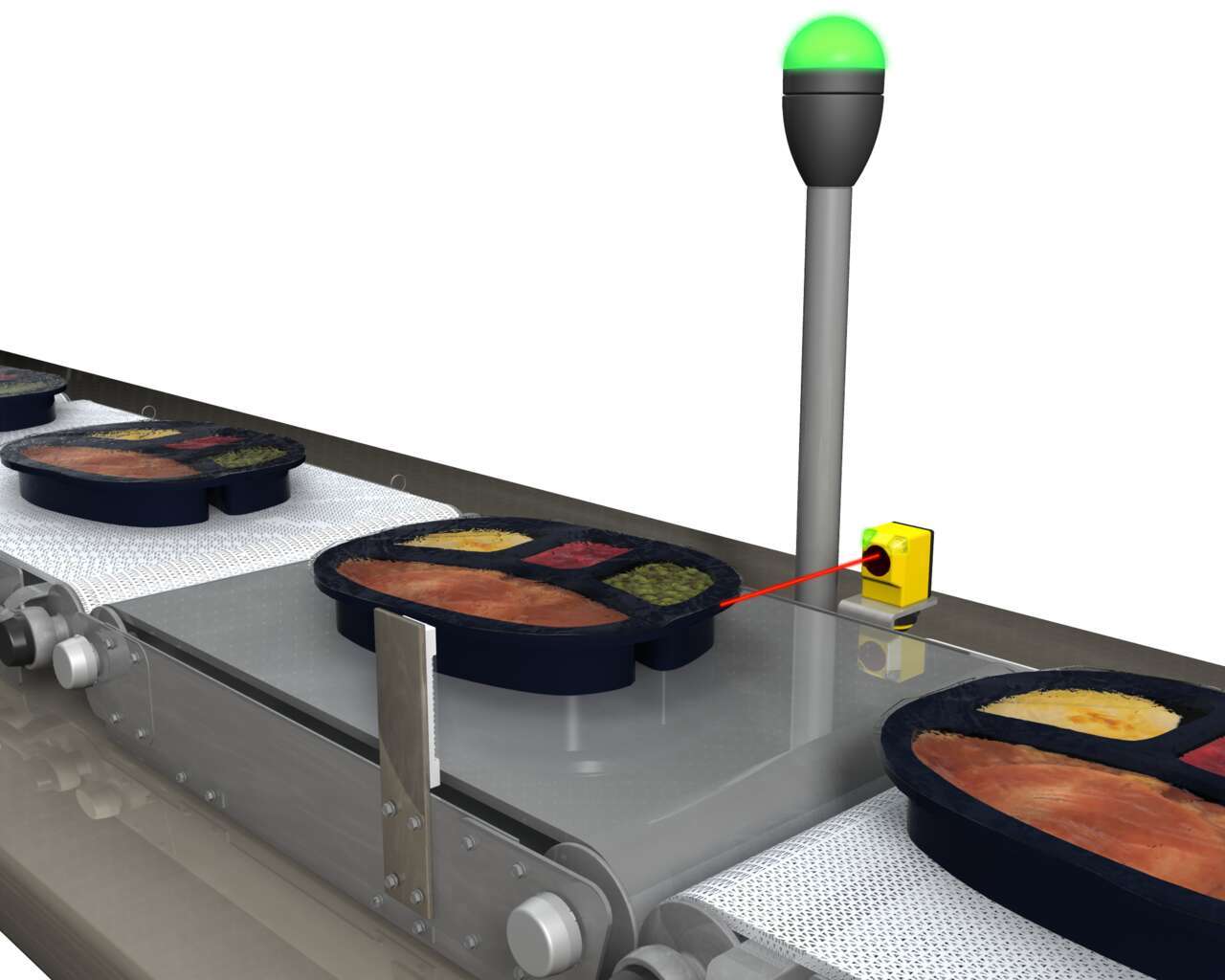

Efficiency and Simplicity Through Intelligent Automation

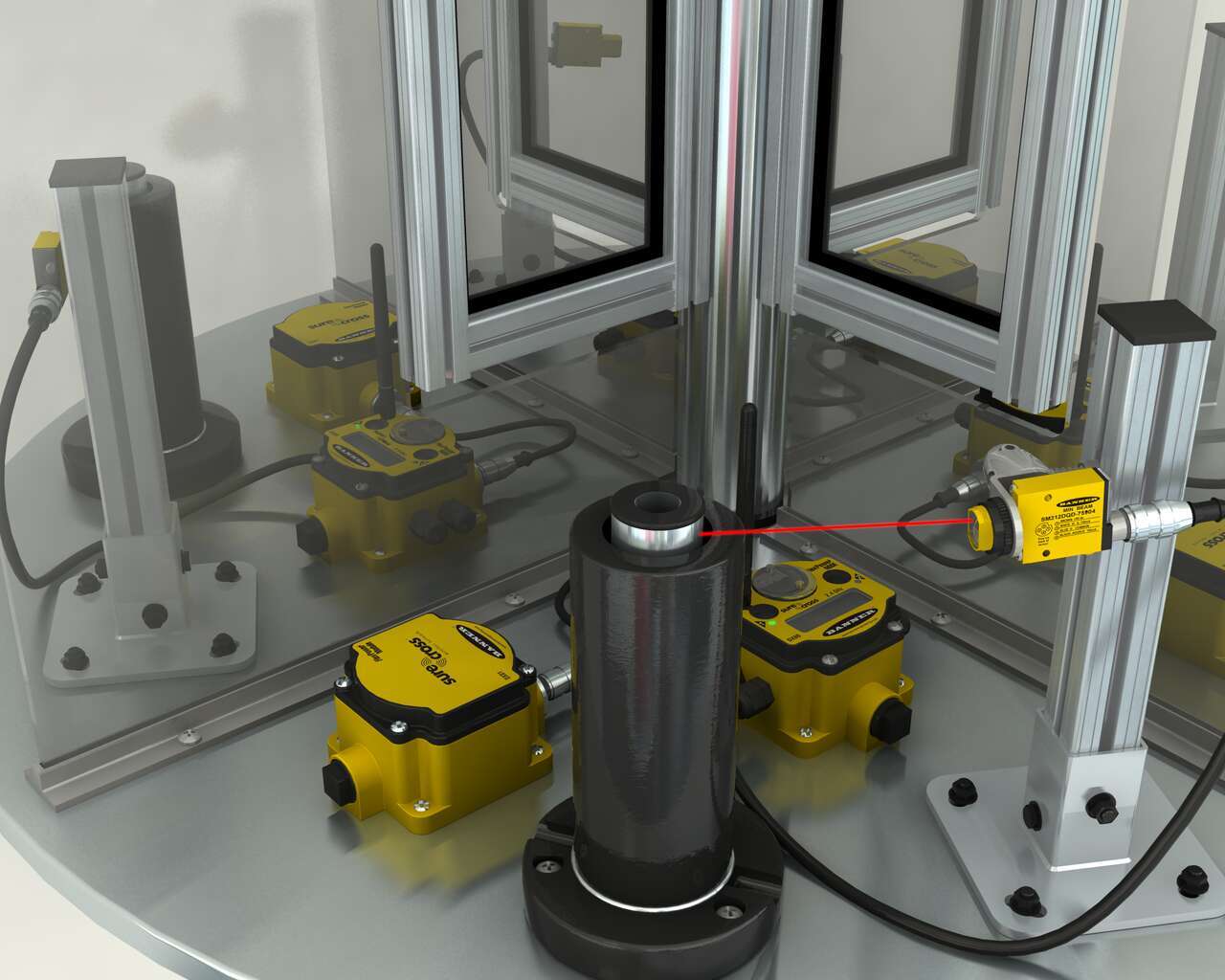

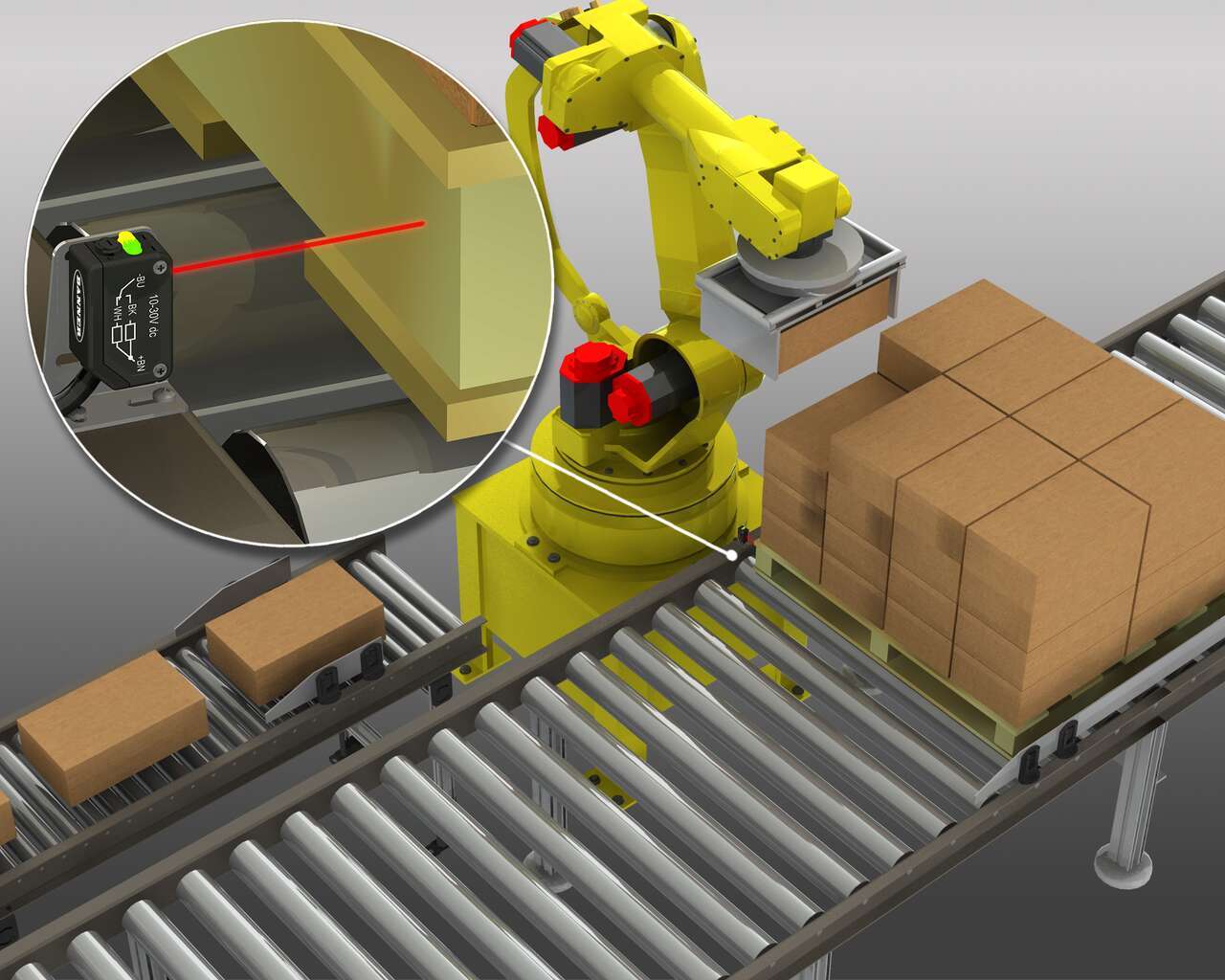

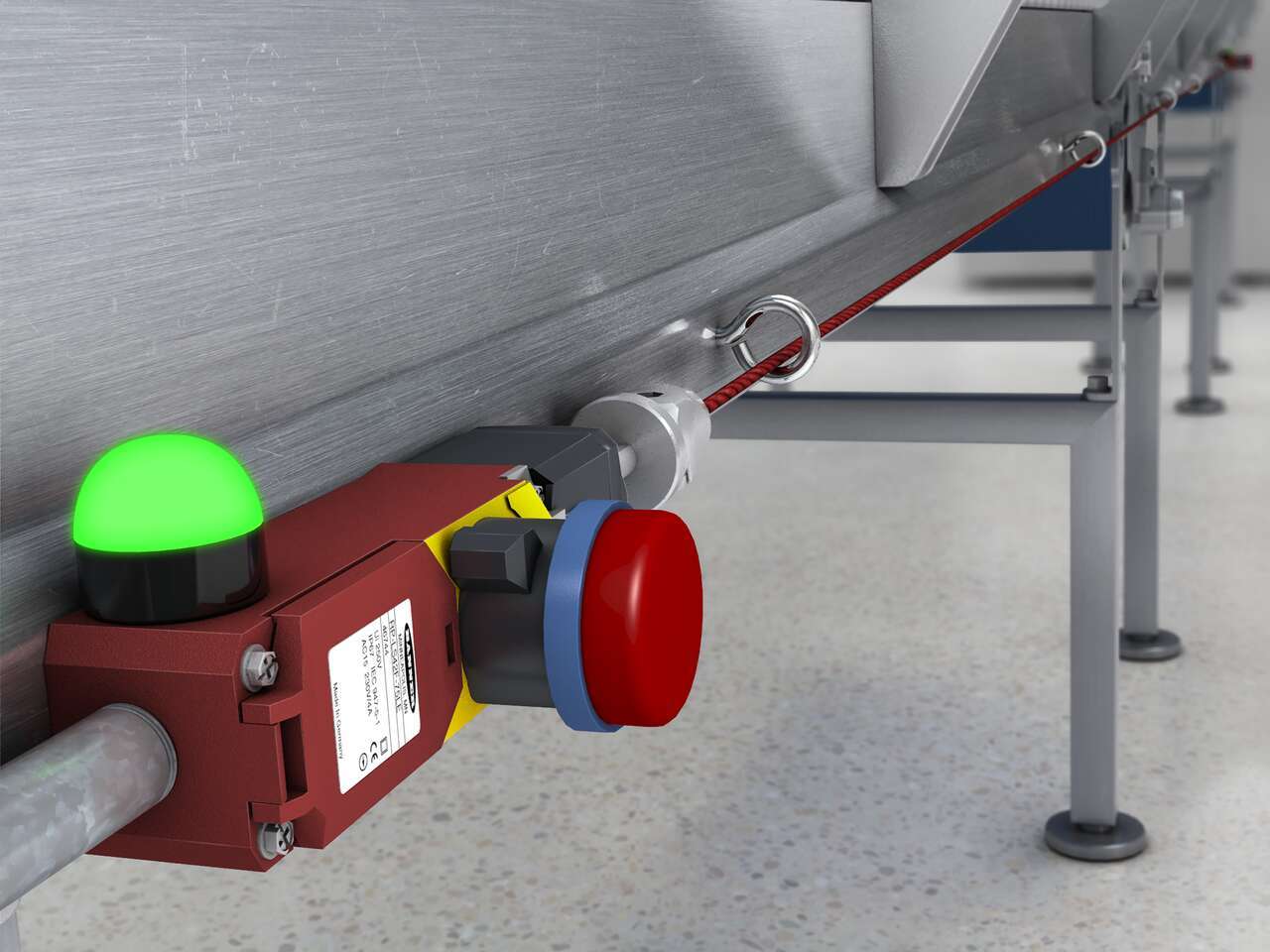

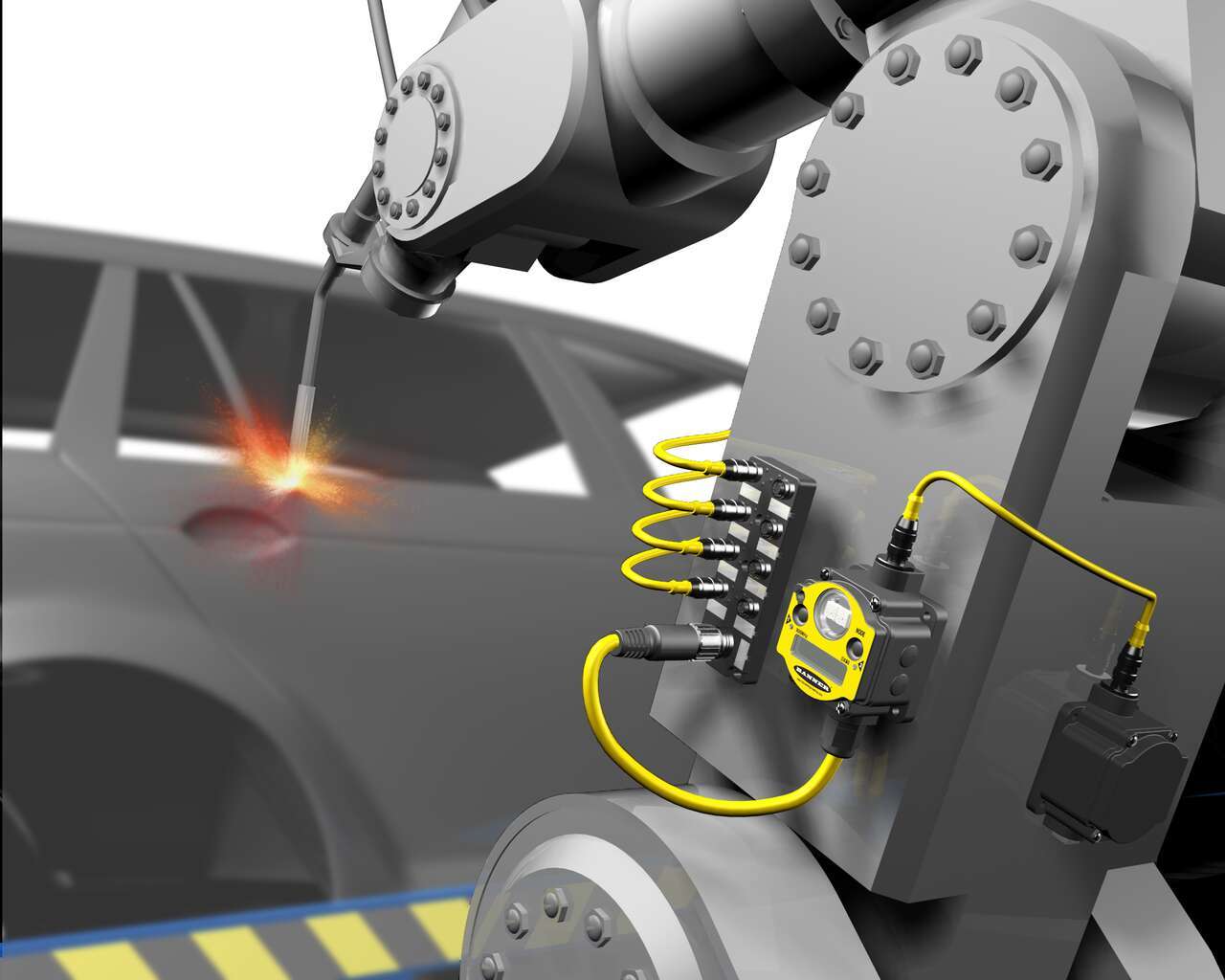

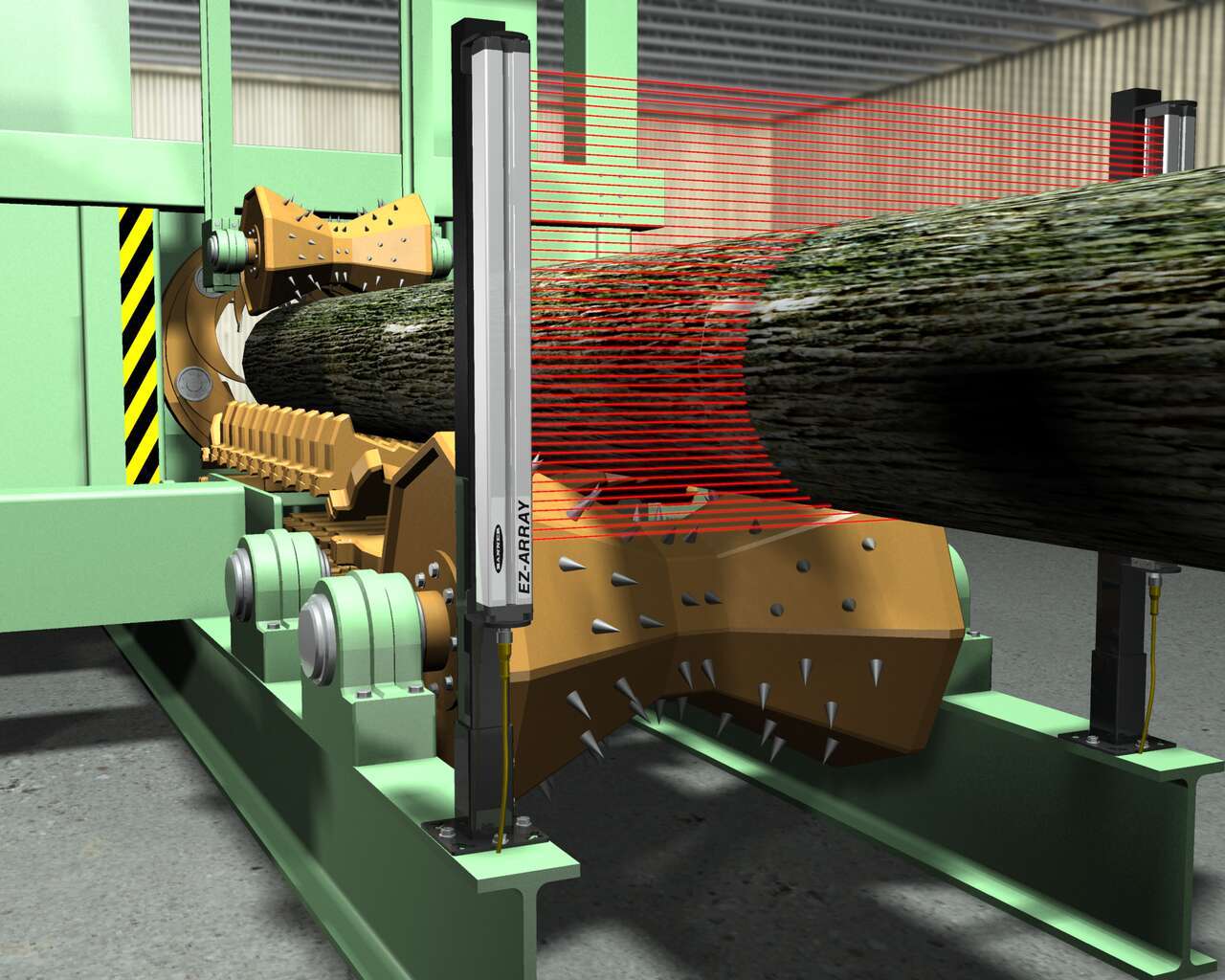

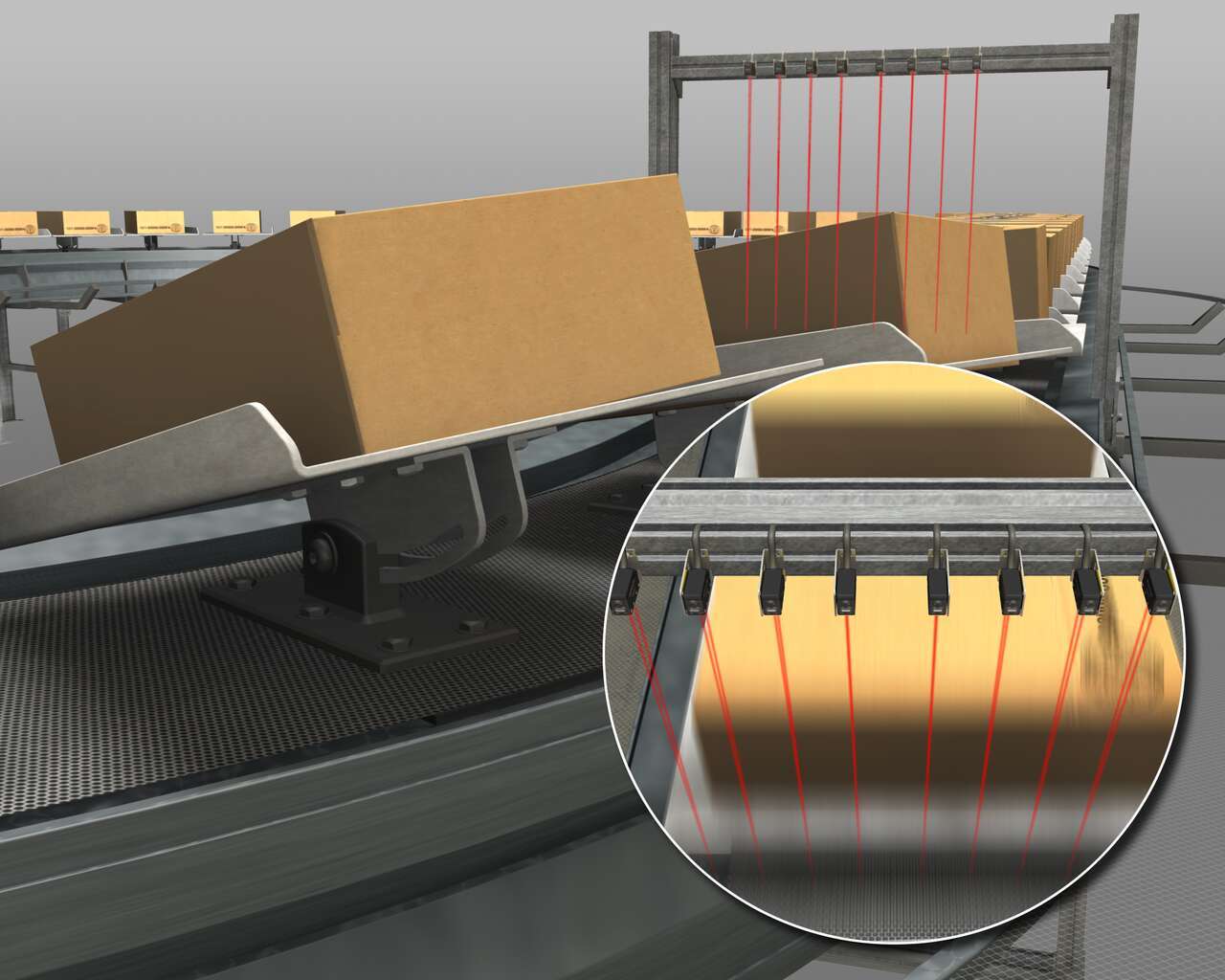

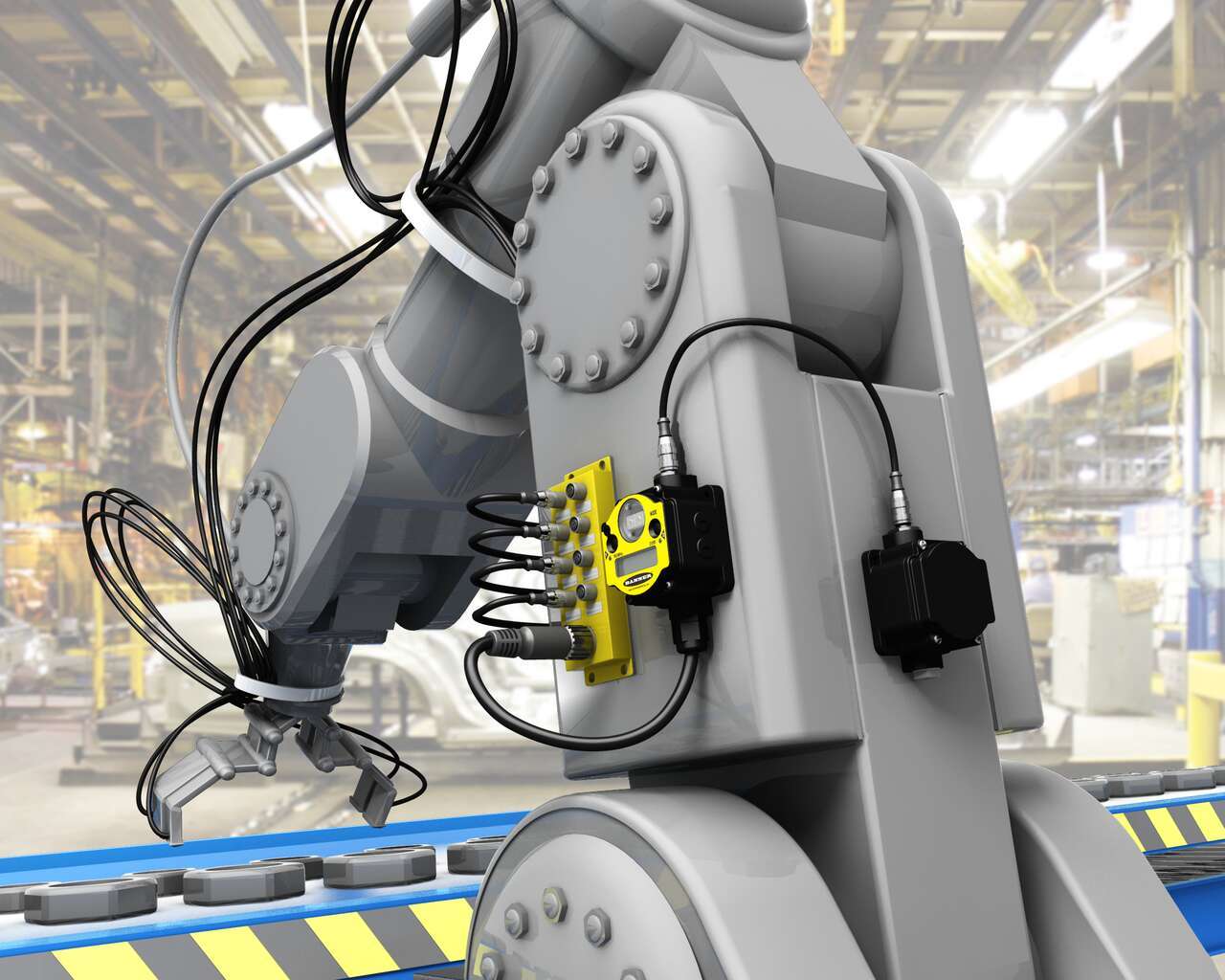

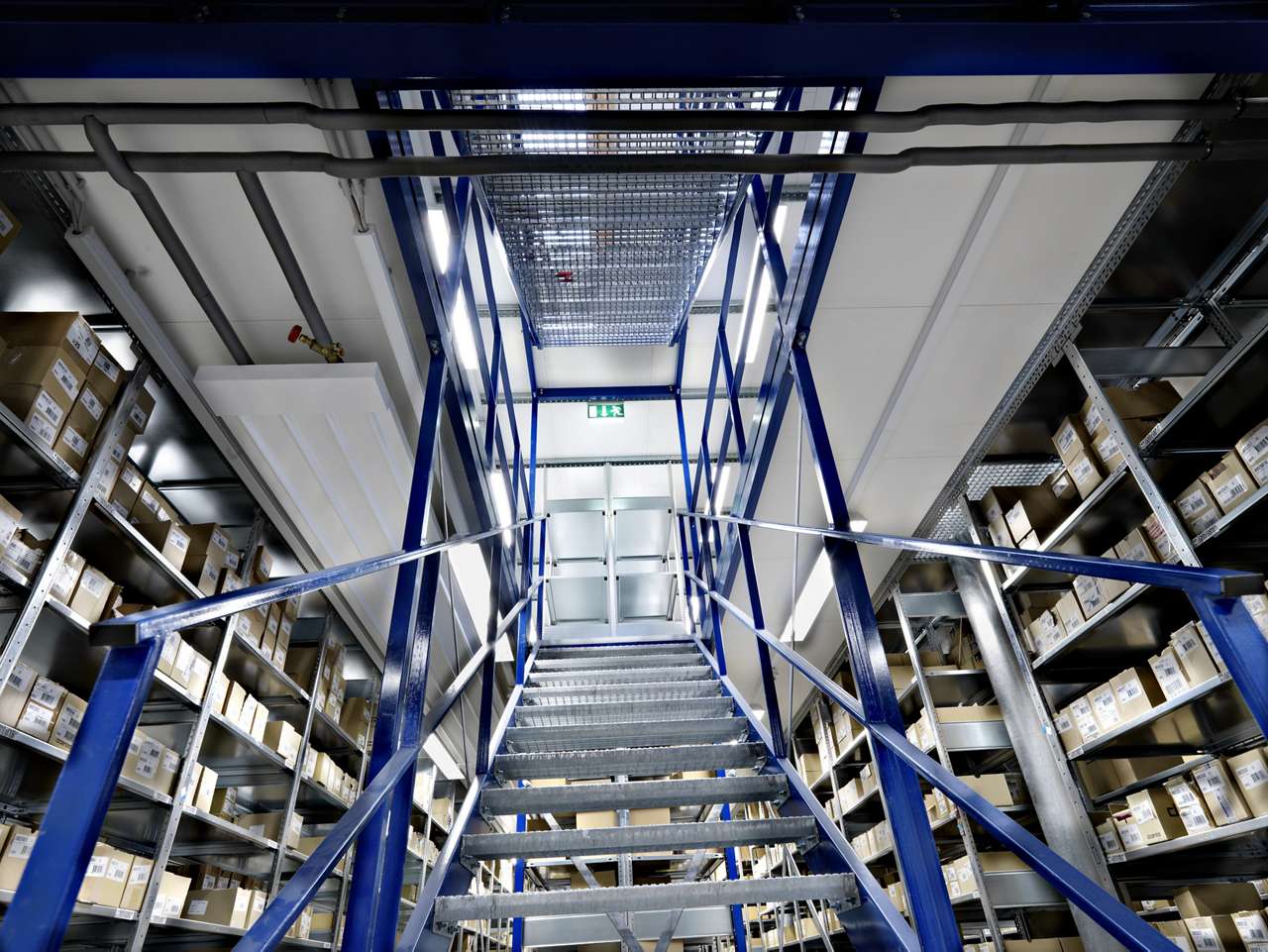

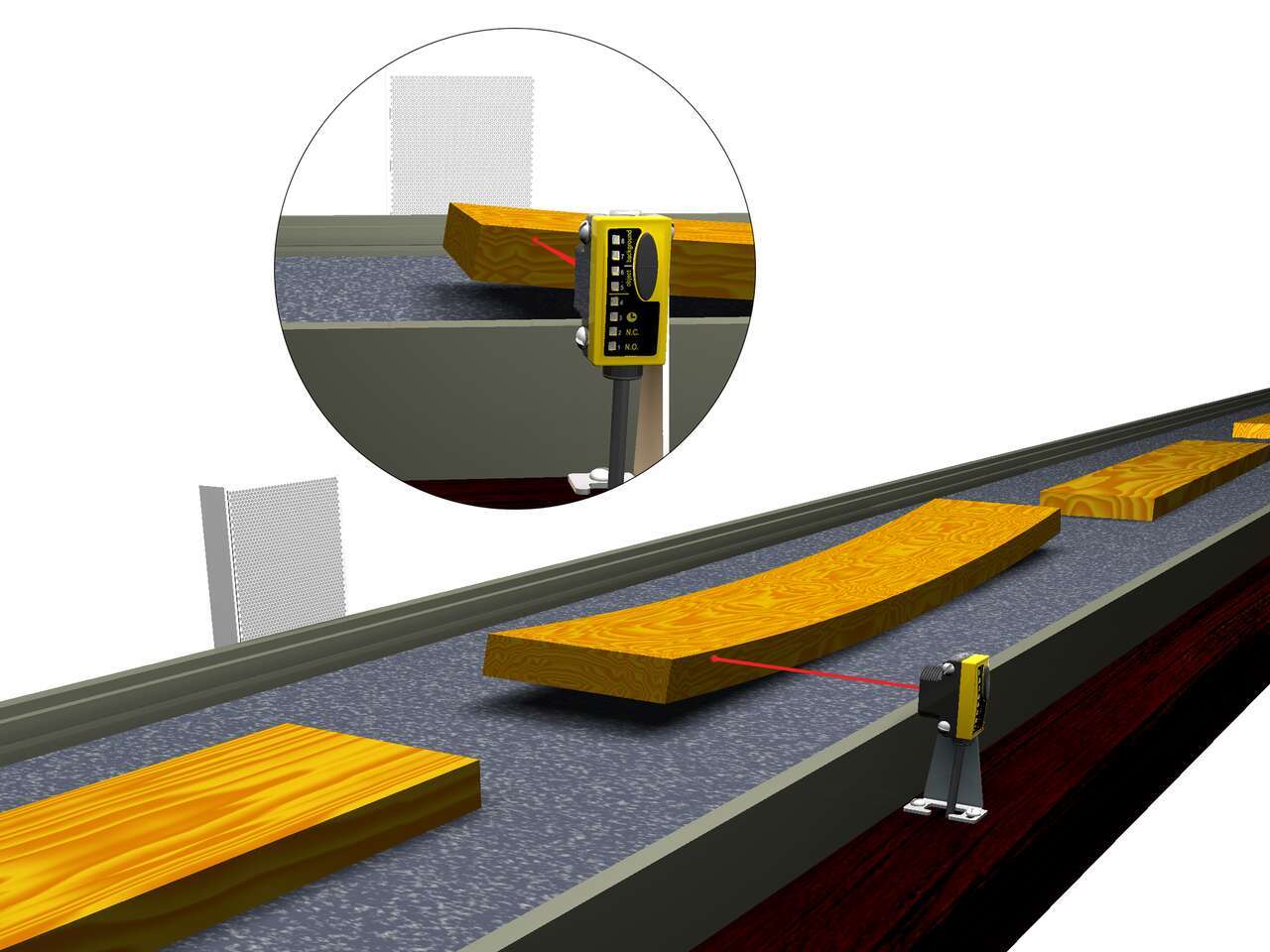

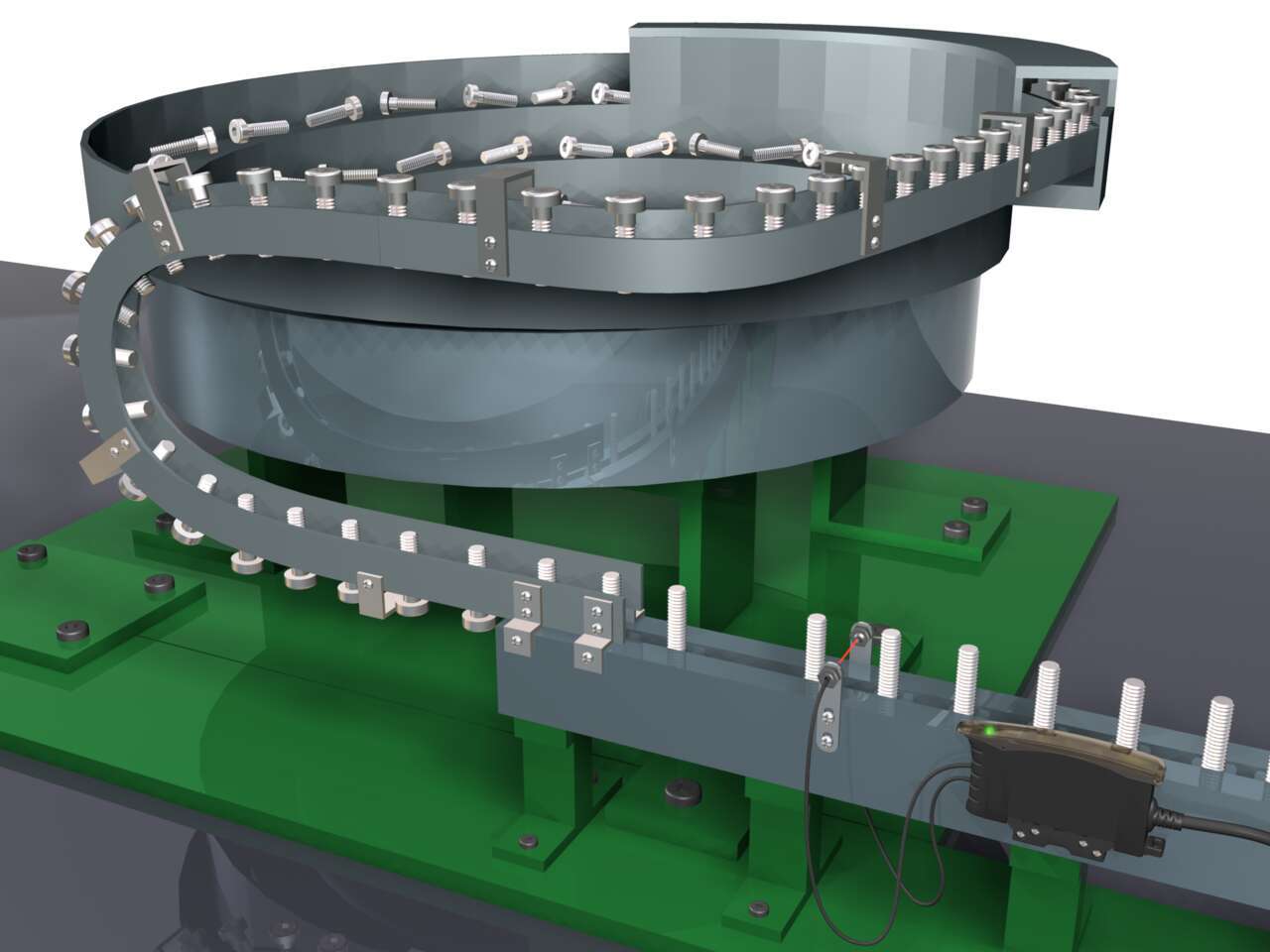

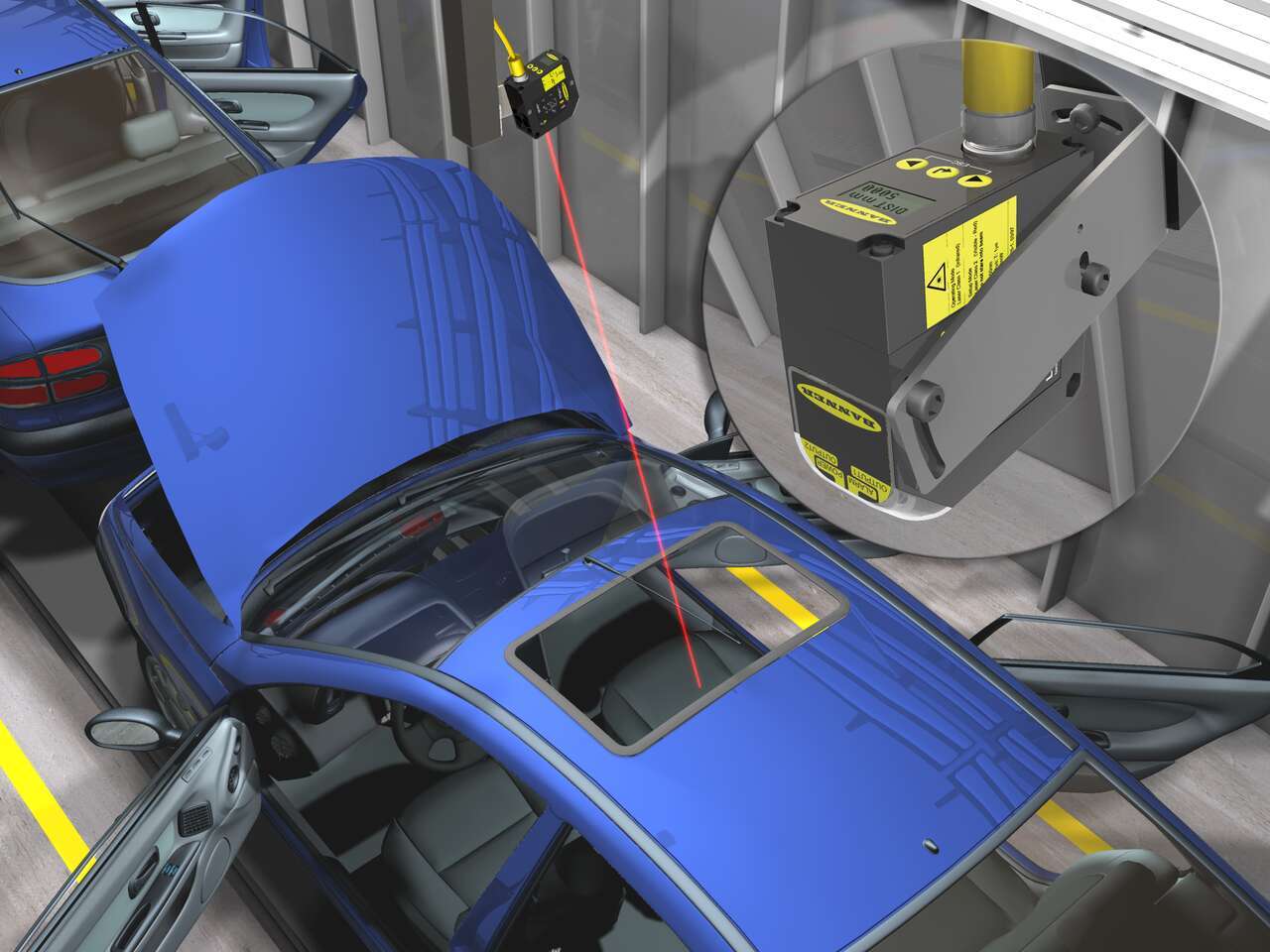

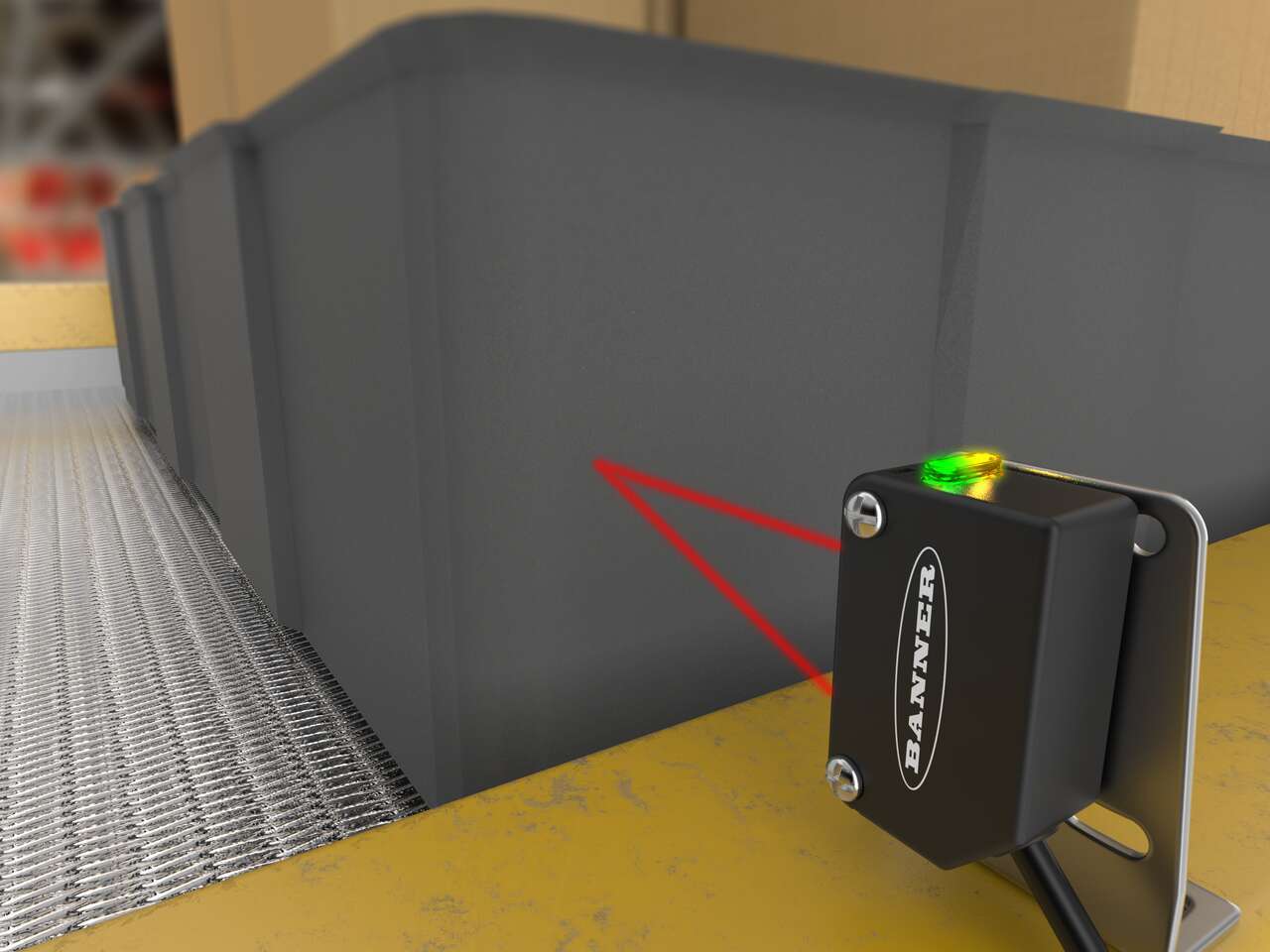

Reliable, versatile, and easy to use and implement, solutions from Banner Engineering help companies solve challenging problems, be more competitive, and achieve their automation goals. Supported by the most comprehensive catalog of automation products in the industry as well as a team of highly-trained, highly-skilled industry experts and solution architects, we provide smart, high-performance solutions that solve a diverse range of applications.

.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)