Smarter Measurements.

Better Solutions.

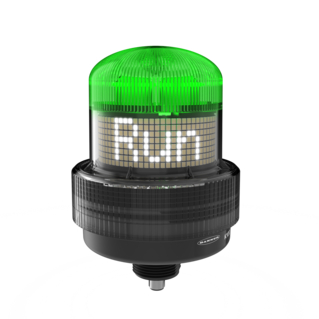

Smarter Lighting.

Better Solutions.

Smarter Safety.

Better Solutions.

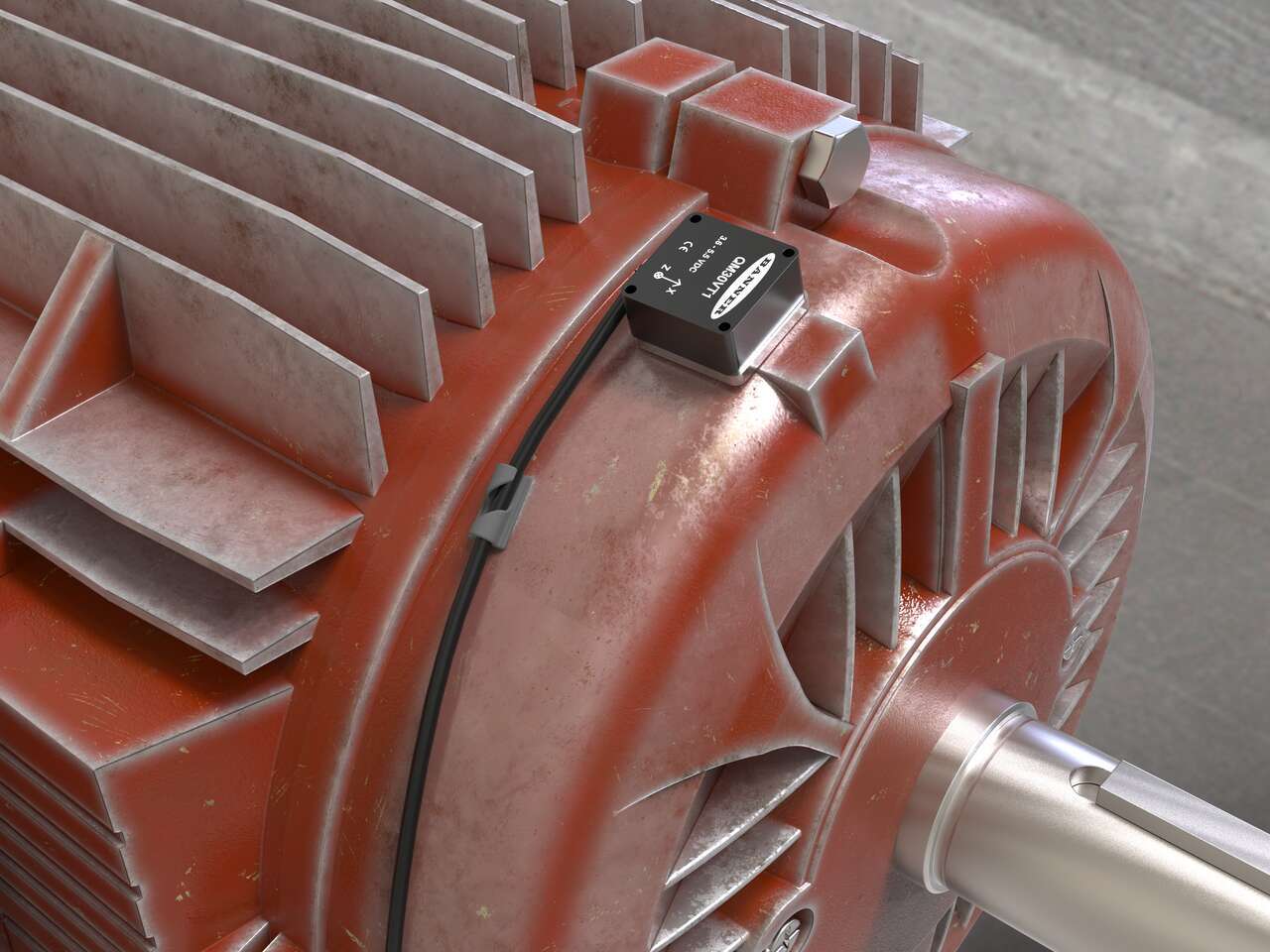

Smarter Sensors.

Better Solutions.

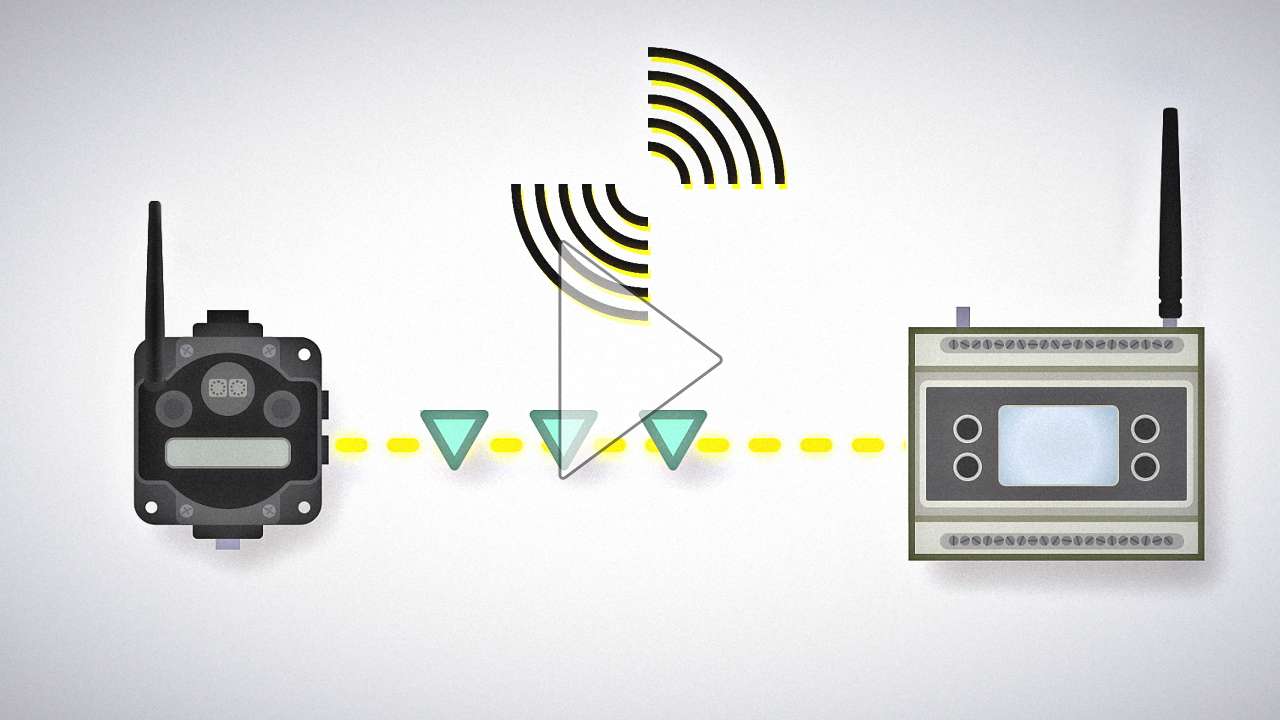

Smarter Wireless.

Better Solutions.

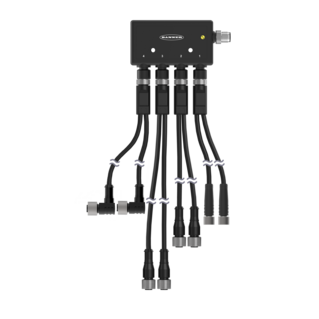

Smarter I/O.

Better Solutions.

Smarter Connectivity.

Better Solutions.

Smarter Monitoring.

Better Solutions.

New Products

-

3 Dec 2025

3 Dec 2025SD50 Wireless Status Display

-

19 Nov 2025

19 Nov 2025S15Y Slimline Splitters

-

13 Nov 2025

13 Nov 2025High Frequency RFID Read/Write Heads and Tags

-

12 Nov 2025

12 Nov 2025Expanded Selection of Banner Ethernet Cordsets

-

29 Oct 2025

29 Oct 2025Q20-2 Laser Measurement Sensor

-

22 Oct 2025

22 Oct 2025R50 Zero Pressure Accumulation Control Module

-

24 Sep 2025

24 Sep 2025Wireless Battery-Powered 3-Axis Vibration Monitoring

-

3 Sep 2025

3 Sep 2025Ethernet CAT6A X-Code Field Wireables

-

27 Aug 2025

27 Aug 2025K100 Programmable Display Beacon

-

21 Aug 2025

21 Aug 2025High Flex Cordsets

-

20 Aug 2025

20 Aug 2025PS67 Power Supply

-

See All New Products

Who We Are

Global Automation Products & Solutions

At Banner Engineering, our dedication to developing quality products and providing personable service enables us to deliver smart solutions to our customers across industries and geographies.

-

NEW

Remote I/ORemote I/O products optimize control system performance and simplify system design for machine builders and controls engineers.

-

Condition Monitoring Made Easy

Condition Monitoring Made EasyThe Asset Monitoring Gateway (AMG) with SNAP ID is simple and easy to use, delivering insights to help make informed decisions about an asset that can increase productivity and prevent unexpected maintenance.

-

Snap Signal

IIoT Made EasyBanner’s Snap Signal family of plug-and-play products represents a new way to unlock your valuable machine data.

-

Pro Products

Give Your Light Full ControlWhether you need Illumination or Indication, the family of Pro products from Banner gives your machines a voice for dynamic advanced capabilities and control throughout your facility.

-

Vibration Sensors for Industrial Automation

Vibration Sensors for Industrial Automation -

In-Series Diagnostics (ISD)

In-Series Diagnostics (ISD)In-Series Diagnostics (ISD) makes it easy to troubleshoot machine safety systems, prevent faults from occurring, and reduce downtime.

Banner By the Numbers

1966

Established 55+ Years Ago

5,500+

Our Sales and Support Network

30+

Offices on 5 Continents

4

Global Manufacturing Locations

10,000+

Innovative Products

Success stories

- Natalia Gutierrez, Representative at Tulip

Success stories

- Chris Budney, Engineering Team Lead, IRIS Factory Automation

Success stories

- Justin Witbeck, Mechanical Engineer, In the Ditch Towing Products

Success stories

- Jeff Kay, Representative at Expand Machinery

Industries We Serve

Our solutions automate your production, increase the efficiency of your equipment and process, and improve safety and quality. Across industries, we are the trusted partner for solving your application needs, furthering your pursuit of smart automation, and realizing the potential in your process with actionable data.

Who We Are

Engineering. It’s In Our Name.

It’s In Our DNA.

Customers worldwide choose Banner for its reputation of quality engineered products. With engineers employed in nearly every major department, engineering is in our DNA. Our commitment to innovation shows through a continuous, market-driven evolution of products and technology. We believe that if our product meets our expectations, it will exceed yours. And we back these products with a global network of 5,500 factory and field representatives who stand ready to support our customers, wherever they are.

Learning Resources

- Applications

- Banner Blog

- Success Stories

- Videos

- White Papers

-

The Visual Factory

-

Guide to Car Wash Monitoring and Proactive Maintenance

-

10 Things You Should Know about Radar

-

Easily Measure Bulk Container Fill Levels

-

How To Use IP & NEMA Ratings To Choose The Right Sensor

-

Features and Benefits of Banner's SI-GL42 Guard Locking Safety Switches

-

Selecting the Right Interlock Switch Safety Category Level

-

Ultrasonic Sensors: Answers to Frequently Asked Questions

-

See All Banner Blog Posts

-

Increasing Productivity with Pick-to-Light System

-

Illuminate Web Inspection Stations with Rapid-Install LEDs

-

Sensors to Measure Movement Range

-

LED Lights Illuminate Control Cabinet

-

Tracking Package Location through Conveyor Roller Gaps

-

Monitor Vibration: Prevent Costly Downtime in Boiler Room

-

Predictive Maintenance for Crane Motors and Gearboxes

-

Monitor Fill Level of Liquid in Mobile Drum

-

See All Success Stories

-

LM Series Precision Laser Measurement Sensor

-

How to Use Tower Lights to Gather Production Data for IIoT

-

S22 Pro Series Indicators and Touch Buttons

-

Multicolor LED Strip Lights with EZ-STATUS®

-

HLS27 LED Strip Light for Hazardous Locations

-

Next Generation T18-2 Series Washdown Sensors

-

![iVu Series Vision Sensors [Video]](/content/dam/banner-engineering/projects/video-thumbnails/i_Vu_Video_Thumbnail-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

iVu Series Vision Sensors

-

Wireless Solutions That Keep Your Network and Data Secure

-

See Video Library

-

5-Step Guide to Modernize Your Factory

-

What IIoT Means for Manufacturing

-

Preventing Downtime in Tire and Rubber Manufacturing

-

Five Steps to Implementing a Predictive Maintenance Program

-

Smarter Lighting

-

Considerations for Lighting in a Manufacturing Environment

-

Prevent Motor, Fan, and Pump Failure

-

Machine Safety Fundamentals

-

See All White Papers