Luminescence Sensors: Answers to Frequently Asked Questions

Image: Luminescence sensor detects tamper seal

Summary: Luminescence sensors use UV light, invisible to the human eye, to cause the target material to glow in the visible spectrum. Luminescence sensors are much more sensitive than a regular photoelectric and are especially useful in difficult applications like detecting clear materials or differentiating between color marks and a similar color background. This article provides answers to commonly asked questions about luminescence sensors.

Q: What is luminescence?

Luminescence is cold light emitted due to a chemical reaction that results from the absorption of radiant energy. This is in contrast to incandescence where visible light is released as a result of the temperature of the emitting body.

Q: How does a luminescence sensor work?

A luminescence sensor can produce a detectable visible emission by shining invisible UV light on a target. When the invisible UV light projects on a luminescent material like an adhesive, the light "excites" electrons in the adhesive, causing it to emit visible light. When the sensor detects this glow, it sends an output to a control.

Q: What’s the difference between luminescence and fluorescence?

Fluorescence falls under the category of luminescent light. Types of luminescent light include fluorescence, phosphorescence or bioluminescence. These types of luminescence are distinguished by the source of energy that produces the release of electromagnetic radiation and by the decay time duration.

Q: Will a luminescence sensor be able to detect a fluorescent mark?

Yes, because it emits UV light but detects visible waves, a luminescence sensor can distinguish between the fluorescent material and other highly reflective materials.

Q: What types of materials can be detected by a luminescence sensor?

Some materials include the following: glue, detergent, adhesives, plastics, fluorescent chalks, markers or crayons, grease and oils, UV pigments or brighteners, and most hydrocarbon-based material.

Q: What if I don’t have these materials in my application?

It’s possible to add luminophores to the product you are trying to sense since they are invisible to the human eye. Generally speaking, the more sensitive the sensor, the lower the level of luminescence required for detection. Less sensitive sensors may require an additional step in the production process, and a substantial cost over time, to add luminophores.

Q: How does light and dark operate work with a luminescence sensor?

With light operate, you are trying to detect a target that is more luminescent than the background. Sensing the lighter target will close the normally open output, causing the output to conduct current.

With dark operate, you are trying to detect a target that is less luminescent than the background. Sensing the darker target will close the normally open output, causing the output to conduct current.

Q: What is the advantage of a luminescence sensor over a photoelectric?

Luminescent sensors are especially useful in detecting objects that would otherwise be invisible. For example, you can create a mark on a target that will only become visible when exposed to UV. This invisible mark will not affect the look of the packaging.

Q: Do I need special lighting for a luminescence sensor?

No. The sensor comes with a UV LED built in.

Q: My factory has a lot of bright lights. Will this affect the sensor’s performance?

It shouldn't affect the sensor’s performance but with some luminescent sensors, setup may be more difficult.

Q: What are some common applications in which a luminescence sensor is used?

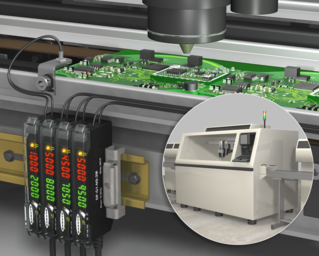

They could be used in lumber optimization, detecting tamper-evident seals and leaking oils, and the verification of the dispensing of liquid thread fastener materials, etc.

Images: Example applications for luminescence sensors

Q: What if both my background and target are luminescent? Will the sensor still work?

In most instances, there is some difference between the luminescence of the background and target. Therefore, you'll be able to successfully teach the sensor to detect one or the other. If the background and target both have the same amount of luminescence, adding luminophores to the target enables the sensor to detect the target. If the difference is slight, the application may require a more sensitive sensor or the addition of luminophores.

Banner can test your samples and recommend a sensor solution. Let us help you solve your application!

Q: What are some differences between Banner's Q26 and QL56 luminescence sensors?

The QL56 offers a longer range and higher sensitivity compared to the Q26. You might find that, in the long run, a more sensitive sensor such as the QL56 is often more cost-effective to operate even with a higher up-front cost. Generally speaking, the more sensitive the sensor, the fewer luminophores will need to be added to the process, which will reduce the overall cost of the application.

For More Information

For more information about luminescence sensors, contact one of our experts or sign up below to receive future updates.

Featured Products

Related Articles

How to Use an Infrared Photoelectric Sensor for Water-Based Liquid Detection

Learn how Banner’s QS30 H2O photoelectric sensor uses a unique optical property of water to reliably detect the presence or absence of water.

Fiber Optic Sensing Technology: What It Is and How it Works

This article explains what fiber optics are and how they work in industrial applications. Learn important terms and the basics of fiber optic systems and assemblies.

Luminescence Sensors: Answers to Frequently Asked Questions

Luminescence sensors use UV light, invisible to the human eye, to cause the target material to glow in the visible spectrum. This article provides answers to commonly asked questions about luminescence sensors.

How to Choose the Best Sensor for Clear Object Detection

Understand the differences between common sensor types in Clear Object Detection applications, such as ultrasonic vs. photoelectic retroreflective sensors.