All Agriculture Solutions

-

Frost Protection and Soil Moisture Control in Cranberry Bogs

Frost Protection and Soil Moisture Control in Cranberry Bogs

Soil moisture and air temperature sensing ranges are typically under a mile, but the Site Survey tested the signal out to two miles. With the MultiHop Radio and its antenna installed very low to the ground, the Master Radio was installed with a large omnidirectional antenna to maximize the communication range.

-

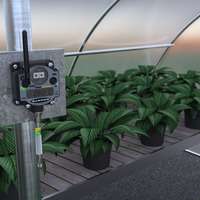

Greenhouse Temperature and Humidity Monitoring

Greenhouse Temperature and Humidity Monitoring

A Sure Cross FlexPower™ Node with internal battery directly connected to a temperature and humidity sensor can provide these measurements without costly conduit or cabling, eliminating the need to manually collect data from multiple sensor locations. IP67 electronics and a variety of filter options make this product suited for the wide temperature and humidity ranges encountered in a greenhouse.

-

Monitor Leaks in Your Critical Applications

Monitor Leaks in Your Critical Applications

Monitor leaks in your critical applications and receive real time alerts when they occur.

-

Bring In IO-link Sensor Data for Tank Level Applications Wirelessly

Bring In IO-link Sensor Data for Tank Level Applications Wirelessly

Wirelessly integrate IO-link sensor data for tank level monitoring with Banner's DXM controllers and T30R sensors for accurate, remote data analysis.