Automotive: Final Assembly Solutions

-

Temperature Sensor Detects Defrost Wires

Temperature Sensor Detects Defrost Wires

An automotive manufacturer was rejecting a supplier’s shipment of rear window assemblies due to faulty defroster grids. The supplier’s existing test procedure measured current draw across the entire heating system to detect an overall failure, but it could not detect the subtle impact of a single heating wire being broken. The window supplier partnered with a Michigan-based machine automation company to create a better test fixture—one that can verify each defrost wire heats to specification prior to shipping.

-

Call for Pickup from an Assembly Station to an AGV

Call for Pickup from an Assembly Station to an AGV

• Remove completed pallets from assembly stations quickly • Enable direct communication from assembly stations to AGVs • Improve process efficiency using turnaround time data to

-

Assembly Timer at Busy Work Station

Assembly Timer at Busy Work Station

K50 Pro touch buttons with IO-Link communication display takt time within workers' sightlines so that the assembly pace stays on track and meets production goals.

-

Detect Installed Glass on Automobile

Detect Installed Glass on Automobile

Sensor solutions to detect the presence of a moonroof on an automobile assembly line where extended range capabilities are required.

-

Vision Sensor to Read QR Codes

Vision Sensor to Read QR Codes

iVu Plus BCR Gen 2 with 25 mm Micro Lens replaces hand held barcode readers to collect data from dense, difficult-to-read QR codes on vehicle transmissions. A WL50S high-intensity LED spot light illuminates the target area.

-

Kitting Operation with Gloves

Kitting Operation with Gloves

Banner’s fixed-field K50 indicator detects gloved hands , sensing when operators select the correct parts during the kitting process. The K50 indicator’s logic function is then able to notify the operator that he/she picked correctly by changing from green to yellow—additional colors can be selected to suite to the manufacturer’s preference. The K50’s ability to detect black gloves is especially important for lean manufacturing processes where workers typically wear dark gloves.

-

Long Bin Pick-to-Light

Long Bin Pick-to-Light

The EZ-LIGHT PVA pick-to-light sensors provide a reliable error-proofing solution for various operation systems. The light indicate to assemblers which items to pick and in which order to pick them.

-

Improving Production with Pick-to-Light Systems

Improving Production with Pick-to-Light Systems

A Banner wireless solution is a simple way to optimize inventory, reduce errors, and minimize waste. Each Sure Cross Performance Node with I/O Mapping can be equipped with up to six EZ-LIGHT operator indicator lights. The Sure Cross Gateway is conveniently located at a central location where maintenance personnel and management can monitor the parts consumption throughout the site.

-

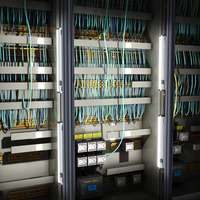

LED Lights Illuminate Control Cabinet

LED Lights Illuminate Control Cabinet

Operators access machine systems through the control cabinet and need Intense illumination of the cabinet facilitates for maintenance and management.

-

Superior Light Distribution with LEDs

Superior Light Distribution with LEDs

American Hoffmann Corporation chose WLB32 LED light bars to illuminate work areas, enclosures and control cabinets, replacing fluorescent light fixtures. The superior light distribution offered by the WLB32 LED lights lights, as well as the ease of installation were key factors in the company's decision.

-

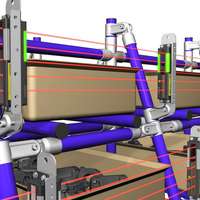

Long-Range Inspection in Automotive Assembly

Long-Range Inspection in Automotive Assembly

As vehicles move forward on an automotive assembly line, an L-GAGE LT7 time-of-flight laser sensor is directed inside the sun roof to verify that the car seat has been installed and is in the correct position.

.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)