-

Industries

-

Beverage

-

Secondary Beverage Packaging

-

Coding & Marking

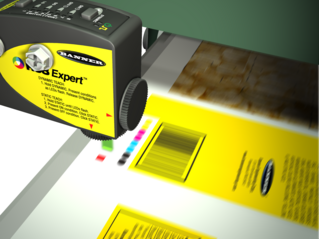

Coding & Marking Solutions for Beverage Packaging

The beverage industry has many rules and regulations in place to make sure that the highest quality products are being delivered to customers. In order to keep track of when and where bottles were filled and packaged, date/lot codes need to be present on the bottles.

Ordinarily, the date/lot codes indicate when a product was finished and exactly which manufacturing plant it was made in. Printing these codes onto labels or bottles is necessary for a company’s quality control and tracing purposes. If a product were to be recalled or needed to be tracked for any other reason after it has left the facility, date/lot codes aid in that process. This is especially important in the beverage industry as the distribution area is very large and recalls can affect countless households.

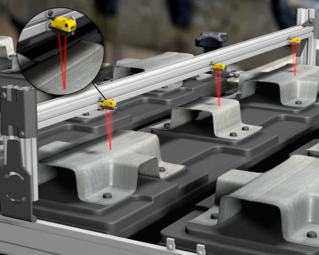

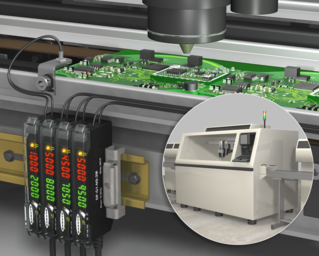

Batch coding machines are used to print easy-to-read and lasting date and lot information onto bottles in order to meet industry requirements. Banner Engineering offers a variety of products that would work very well in the beverage industry to reduce date coding errors. Using our cost-effective and washdown suitable products, Banner can solve various batch coding applications such as triggering the printer to detecting date code presence and absence. Making use of these quick and responsive sensors, vision systems, or safety equipment helps keep the beverage filling line running smoothly and efficiently.

Featured Applications

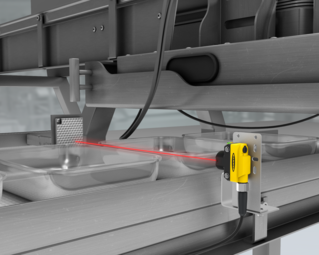

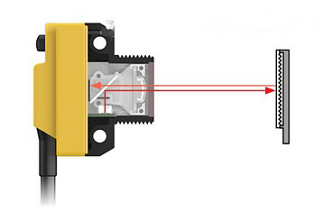

Trigger Sensing on Printer

In the beverage industry, date/lot codes are mandatory on all products in order to identify when and where a product was manufactured. Finding a solution that can accurately identify the bottle caps and then trigger a machine to print the date/lot codes onto the bottle is required.

Related Articles

Shrink Sleeve Labeling at High Speeds

A leading manufacturer of labeling equipment offers high-speed shrink sleeve label applicators designed to process 800 bottles per minute. To maximize the machine’s performance potential, the company wanted to install sensors capable of consistent detection and output for high-speed bottling.

In A World of Jams

Jam Detection is a serious issue for material handling and logistics. Read about what Banner is doing to help solve these occurrences.

The Smart Factory: IIoT Capabilities for Manufacturers

This article highlights three critical IIoT capabilities of the smart factory: remote monitoring, predictive maintenance, and process optimization.

Radar Sensor Frequently Asked Questions

Answers to frequently asked questions about radar technology and Banner's radar sensor products.

Vision 101: When to Use a Vision Sensor

Many users find vision challenging, and complex vision systems certainly can be overwhelming, but vision is a powerful tool for many applications. Vision sensors are an especially great choice for users getting started with vision. This article explains what vision sensors are, when to use a vision sensor, and when to upgrade to a smart camera.

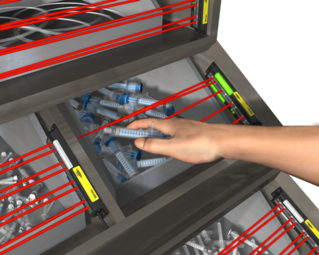

3 Food Safety Hazards & How to Choose Sensor Solutions

Learn 3 of the most common food hazards that can result in product recall and the sensor technologies that can help ensure food safety in each scenario.

Tank Level Monitoring: Benefits of Wireless Solutions

Properly monitoring and managing tank levels can help improve efficiency and increase productivity and profitability. Read this article to learn about the advantages of wireless remote tank level monitoring.

PVC Cable or PUR Cable: How to Choose

PVC and PUR are two of the most common cable jacket materials. Which one should you choose? This guide helps you determine the right one for your application.

How to Choose an Industrial Safety Controller

Read the article to learn 5 features to look for when choosing an industrial safety controller.

3 Photoelectric Sensing Modes and How to Choose

Sensing mode is one of the most important criteria when selecting a photoelectric sensor. Learn the most common sensing modes and typical applications for each.

How Remote Monitoring Improves Machine Maintenance

Read the article to learn more about how wireless IIoT technologies are making machine maintenance easier and more effective.

What is Excess Gain and How to Use It To Choose a Sensor

This article explains what excess gain is, how it is measured, and general guidelines for how much excess gain is needed for industrial sensing applications.

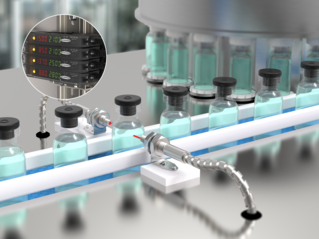

Smart Sensors: IO-Link for Remote Monitoring and OEE

This article describes how IO-Link provides users with remote monitoring capabilities for sensors and can help increase uptime, productivity, and throughput.

Plastic or Glass Fiber Optics? How to Choose

This article explains the differences between glass and plastic fiber optics and how to choose the right fiber optic technology for your application.

Fiber Optic Sensing Technology: What It Is and How it Works

This article explains what fiber optics are and how they work in industrial applications. Learn important terms and the basics of fiber optic systems and assemblies.

When to Use Fiber Optics for Photoelectric Sensing

This article describes advantages, considerations, and common applications for fiber optic sensors.

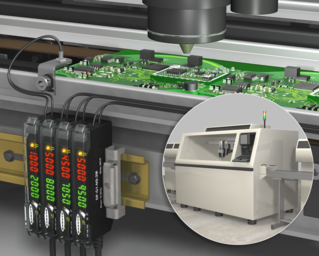

How to Choose Lighting for Harsh Industrial Environments

This article explains common challenges for lighting in industrial environments and considerations for extreme conditions.

Lighting for Manufacturing: The Costs of Ownership

Are LEDs right for your application? Learn the costs of ownership for lighting in manufacturing environments.

Lux/Lumens Calculator: How Much Light Do You Need?

Use our lux/lumens calculator to determine how much light is needed for your industrial lighting application.

When to Use Radar Sensors for Vehicle Detection

Learn how to use a radar sensor for vehicle detection and find out the top 3 advantages of this technology.

3 Advantages of Wireless Magnetometers for Vehicle Detection

Learn how to use a wireless magnetometer for vehicle detection and find out the top 3 advantages of this technology.

3 Solutions for Semiconductor Wafer Presence Detection

See 3 solutions to reliably detect clear and reflective semiconductor wafers in a vacuum chamber.

How to Use an Infrared Photoelectric Sensor for Water-Based Liquid Detection

Learn how Banner’s QS30 H2O photoelectric sensor uses a unique optical property of water to reliably detect the presence or absence of water.

Registration Mark Detection: Why Use RGB Color Mark Sensors

Learn how color mark sensors with RGB technology detect registration marks, when to use a color mark sensor versus true color sensor, and more.

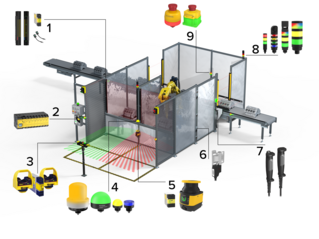

Infographic: 9 Common Machine Safety Devices

Common Machine Safety Devices

Luminescence Sensors: Answers to Frequently Asked Questions

Luminescence sensors use UV light, invisible to the human eye, to cause the target material to glow in the visible spectrum. This article provides answers to commonly asked questions about luminescence sensors.

How to Use Photoelectric Sensors for Tablet Counting

Photoelectric sensors offer many important benefits for tablet counting such as high accuracy, fast response speed, and a clean non-contact approach.

What is a Risk Assessment and Why is It Important?

While it is always best to refer to the standards when planning a risk assessment, here are a few answers to some commonly asked questions.

Lean Manufacturing: 4 Lighting Solutions for Pharma Industry

This article describes several ways lighting can help increase efficiency and reduce waste while ensuring product quality & FDA compliance in the pharmaceutical industry.

Ultrasonic Sensors: Answers to Frequently Asked Questions

Ultrasonic sensors use sound waves to detect and measure in many different applications. This article answers your questions about how ultrasonic sensors work.

How To Use IP & NEMA Ratings To Choose The Right Sensor

Understanding enclosure NEMA and IP ratings is a necessity. This article explains IP ratings vs NEMA so you can choose the right device for your application.

How to Choose the Best Sensor for Clear Object Detection

Understand the differences between common sensor types in Clear Object Detection applications, such as ultrasonic vs. photoelectic retroreflective sensors.

Why Use Polarized Coaxial Optics For Detecting Clear Objects

Clear object detection sensors are sensitive to variations in light and benefit from polarized coaxial optical design to reduce false detection from reflected light.

Tank Level Monitoring: 3 Benefits of a Wireless Solution

Properly monitoring and managing tank levels can help improve efficiency and increase productivity and profitability. Read this article to learn about the advantages of wireless tank level monitoring.