Food: Secondary Packaging

Secondary Packaging in the Food Industry

Banner Engineering offers innovative solutions for increased accuracy, greater productivity and cost savings in secondary packaging.

We are experts in advanced optics, LED, laser, and photoelectric circuits. Our rugged, easy to use sensors are capable of solving a number of the most difficult packaging applications, including regulating product flow and detecting targets with vibrant graphics and clear, shiny packaging. Vision and image sensors from Banner provide comprehensive inspection capabilities for label verification, bar code reading, optical character recognition and date/lot code inspection. Our expanding line of LED lights and indicators provide years of brilliant bright illumination and status indication.

Secondary Packaging Food Applications

View Applications by Machine Type

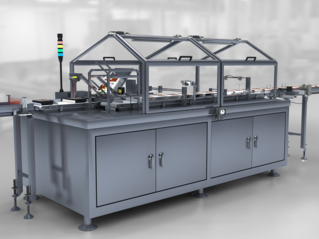

Cartoner

Banner Engineering boosts food packaging with carton stack height sensors and Q4X laser sensors for irregular package detection, ensuring quality and safety.

Case Erector

Banner's case erecting solutions for food packaging: Advanced LE and LTF sensors for variable size detection and bright LED indicators for line monitoring

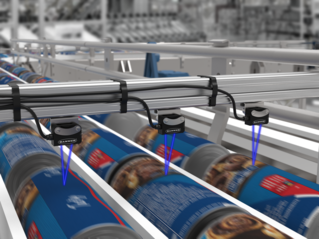

Case Packer

Banner's case packing solutions for food packaging: Barcode monitoring and advanced sensors ensure accuracy and adapt to various sizes and colors.

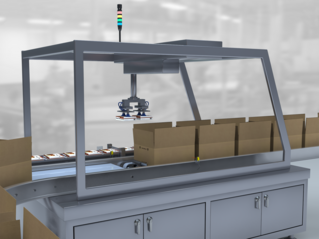

Case Sealer

Banner's food packaging case sealing: LE and LTF laser sensors ensure adaptable, precise sealing for varied case sizes, enhancing production efficiency

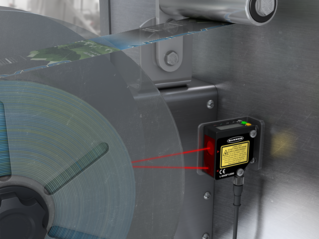

Labeler

Banner's food packaging label solutions use advanced barcode readers for accurate labeling, enhancing traceability and reducing recalls.