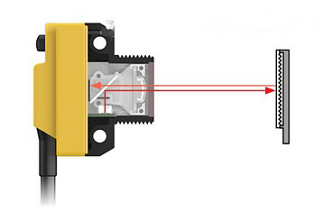

Sensors for Detecting Transparent Objects

By definition, transparent objects allow light to pass freely through them, which is a primary reason why they can be so difficult to detect. Material color, shape, size, faceting, and reflectivity can further complicate detection. Additionally, the harsh, hazardous, washdown and aseptic environments common to many applications challenge the reliability, performance, and longevity of the sensors used to detect transparent materials.

Matching the design, sensing technology, and product features of a sensor to the specific needs of an application makes for a more effective solution. Some sensing technologies may work better in specific conditions or may be more effective with certain materials. Design and feature considerations for sensors used in hygienic environments may be quite different from those of sensors used in packaging applications. Fortunately, Banner Engineering offers sensors designed and developed to overcome these challenges and reliably solve a broad range of clear object detection applications.

Not sure which technology is right for your application? Check out our article on how to choose the right type of sensor for clear object detection.

-

Q4X Series Rugged Laser Distance Sensor

Q4X Series Rugged Laser Distance Sensor

Rugged Q4X laser distance sensor solves many challenging applications and comes in a rugged IP69K rating with FDA food grade stainless steel housing.

-

Q5X Series High Power, Multi-Function Laser Sensor

Q5X Series High Power, Multi-Function Laser Sensor

A powerful, problem-solving sensor in a cost-effective device with industry-standard rectangular housing. With a range from 50 mm to 5 m, the Q5X provides reliable detection of the most challenging targets.

-

QS18 Series All Purpose Photoelectric Sensor

QS18 Series All Purpose Photoelectric Sensor

All purpose photoelectric sensor with universal housing design and 18 mm threaded barrel is an ideal replacement for hundreds of other sensor styles.

-

QM26 & QMH26 Series Washdown Sensor

QM26 & QMH26 Series Washdown Sensor

With a chemical-resistant, FDA-compliant, stainless steel IP69K housing, Banner’s QM26 and QMH26 Washdown Sensors are ideal for food and beverage industries.

-

QMH26 Series Hygienic Washdown Sensor

QMH26 Series Hygienic Washdown Sensor

The QMH26 is designed with minimal grooves and crevices, making it easy to clean and ideal for clean-in-place (CIP) applications.

-

Q26 Series Clear Object Sensor

Q26 Series Clear Object Sensor

The Q26 features coaxial optics and LO/DO switch for clear, translucent or opaque objects including mirror-like surfaces.

-

T30UX Series Temp Compensation Ultrasonic Sensor

T30UX Series Temp Compensation Ultrasonic Sensor

Compact, right-angle ultrasonic sensors with built-in temperature compensation. Available in analog or configurable discrete models. 3 m sensing range.

-

S18U Series Barrel Ultrasonic Sensor

S18U Series Barrel Ultrasonic Sensor

Barrel ultrasonic sensor is Ideal for material handling and packaged goods applications: bottling or liquid level detection. Sensing range < 300 mm.

-

QT50U 8 m Range Chemical Resistant Ultrasonic Sensor

QT50U 8 m Range Chemical Resistant Ultrasonic Sensor

Features a completely sealed, shock-resistant housing that is ideal for tank level monitoring of liquids as well as solids.

-

M25U Stainless Steel IP69K Ultrasonic Sensor

M25U Stainless Steel IP69K Ultrasonic Sensor

Waterproof, stainless steel, ultrasonic sensors were purpose-built to deliver flawless operation in food processing and other sanitary industries.

-

QS18U Series Compact High Speed Ultrasonic Sensor

QS18U Series Compact High Speed Ultrasonic Sensor

Ultrasonic sensor detects items regardless of color, material, or transparency. Senses within 50 to 500 mm window with 15 millisecond response time.

-

T30U Series 2 Meter Range Ultrasonic Sensor

T30U Series 2 Meter Range Ultrasonic Sensor

Right-Angle sensor with 30mm threaded barrel and sensing range up to 2 m. Available with dual discrete, analog, and pump control switching logic for tank level monitoring.

-

Q45U Series Versatile Ultrasonic Sensor

Q45U Series Versatile Ultrasonic Sensor

Versatile sensor accepts programming storage cards for fast, easy sensing parameter changes with ranges up to 3 m.

-

Q45UR Series Remote Transducer Ultrasonic Sensor

Q45UR Series Remote Transducer Ultrasonic Sensor

Precision programmability to resolve object presence to within 0.6 mm. Plastic or stainless steel housing with threaded barrel or Flat-Pak sensing head.

-

T18U Series Opposed Mode Ultrasonic Sensor

T18U Series Opposed Mode Ultrasonic Sensor

High-frequency ultrasonic emitter and tuned receiver for accurate opposed-mode sensing. T-style right-angle housing with 18 mm threaded nose.

-

K50U Series Wireless Ultrasonic Sensor

K50U Series Wireless Ultrasonic Sensor

The K50U wireless ultrasonic sensor makes it easy to monitor mobile and remotely located tanks and totes.