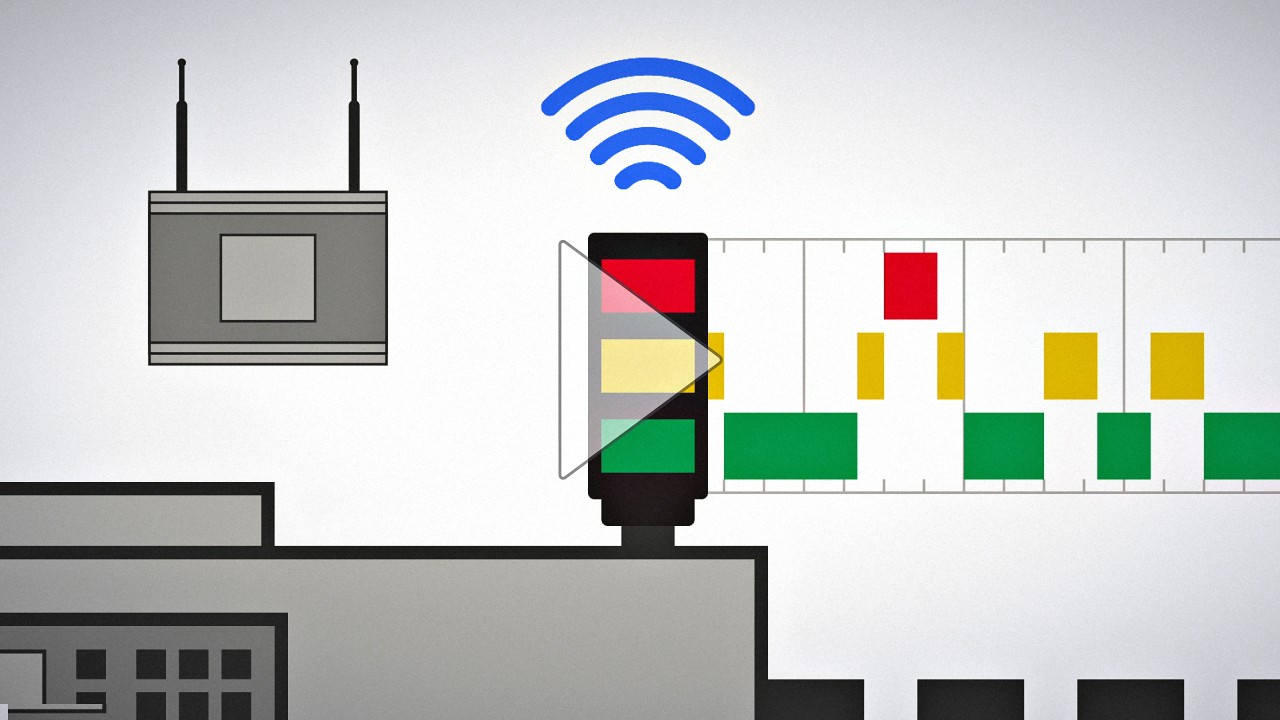

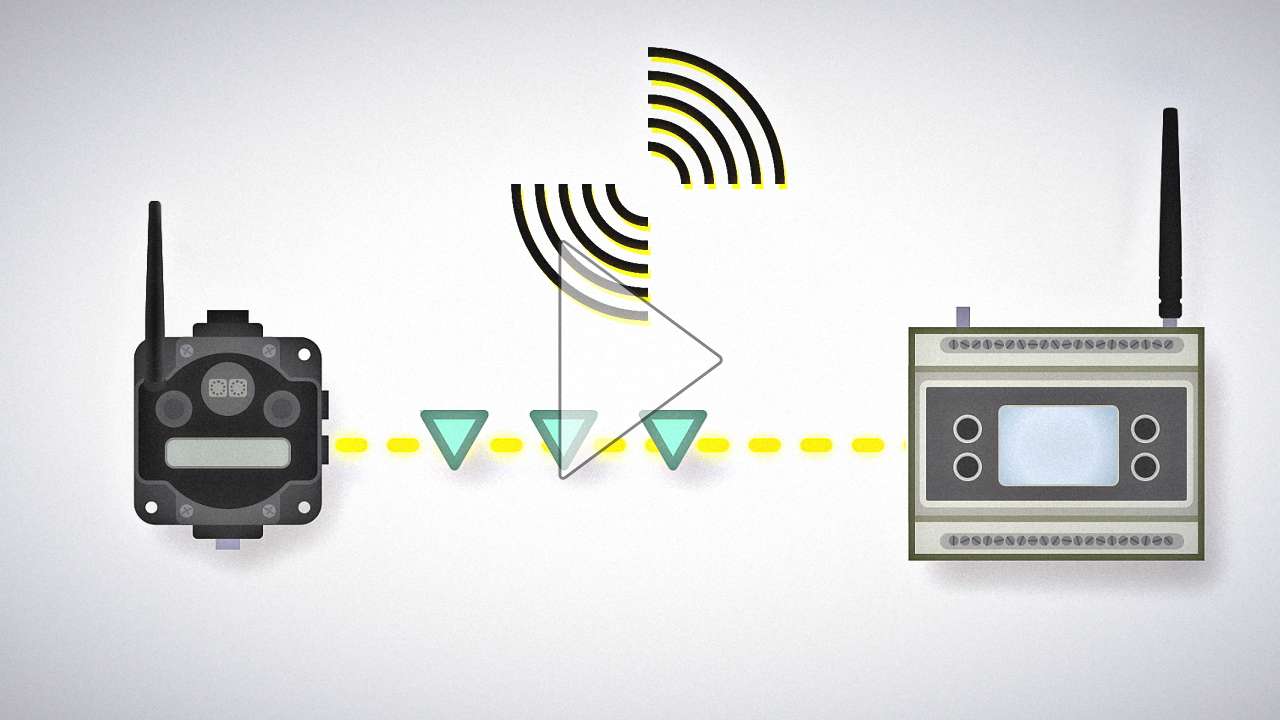

Monitor Fill Level of Liquid in Mobile Drum

The K50U wireless ultrasonic sensor was designed specifically as a non-contact level monitoring solution. Monitoring the levels of epoxy in drums during refill alerts staff of potential overflows before they become a problem.