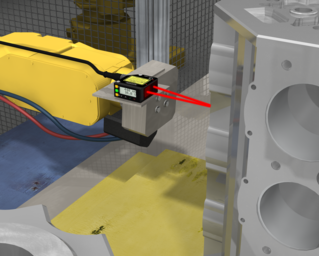

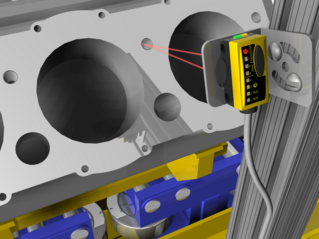

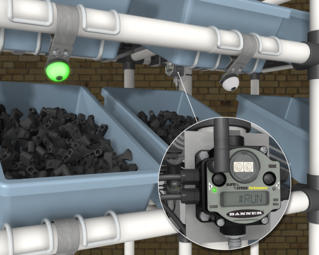

Automotive: Powertrain

Automation at Powertrain Plants

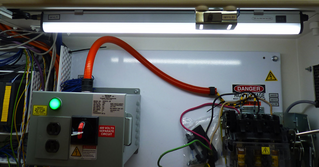

Increased automation at powertrain plants has brought about the need for improved and more cost effective manufacturing methods. In complex assembly operations, product quality and operator safety are primary concerns.

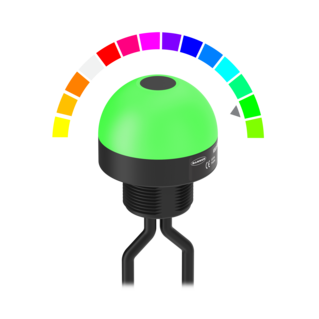

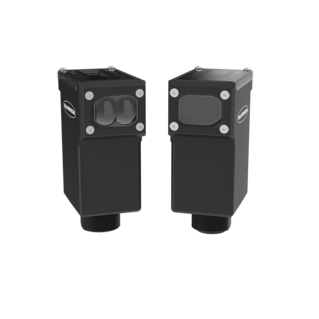

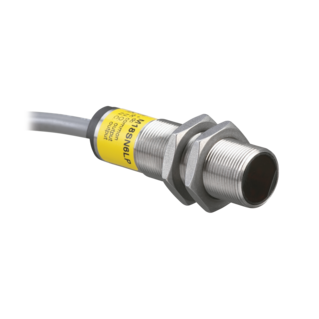

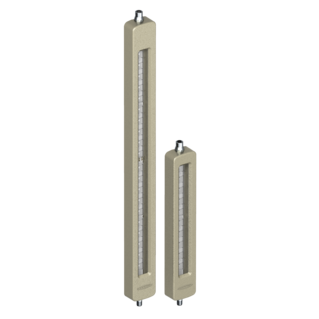

Sensors, safety products, LED lights and indicators from Banner Engineering address these concerns by providing users and machine builders with better value for many applications on assembly lines and in machining areas.