-

Products

-

Lighting and Indication

-

Tower Lights

-

TL50 Core Series 50 mm LED Tower Light

50 mm LED Tower Light

Self-contained tower light indicators use long-lasting LED technology, are simple to install, and provide highly visible operator guidance and equipment indication.

- Hundreds of models available – use the product configurator to find yours

- Installs directly on machine quickly and easily with prewired or quick-disconnect options no assembly required

- Features an entirely self-contained design no controller needed

- Displays up to 7 colors in a single tower choice of 10 colors in standard brightness and 5 colors in high brightness tower lights

- Allows multiple lights to be on simultaneously

- Eliminates false indication from ambient light; indicators appear gray when off

- Available in Universal AC Voltage models

TL50 Core Series 50 mm LED Tower Light

Applications

Proven Solutions that Keep Operations Running

-

-

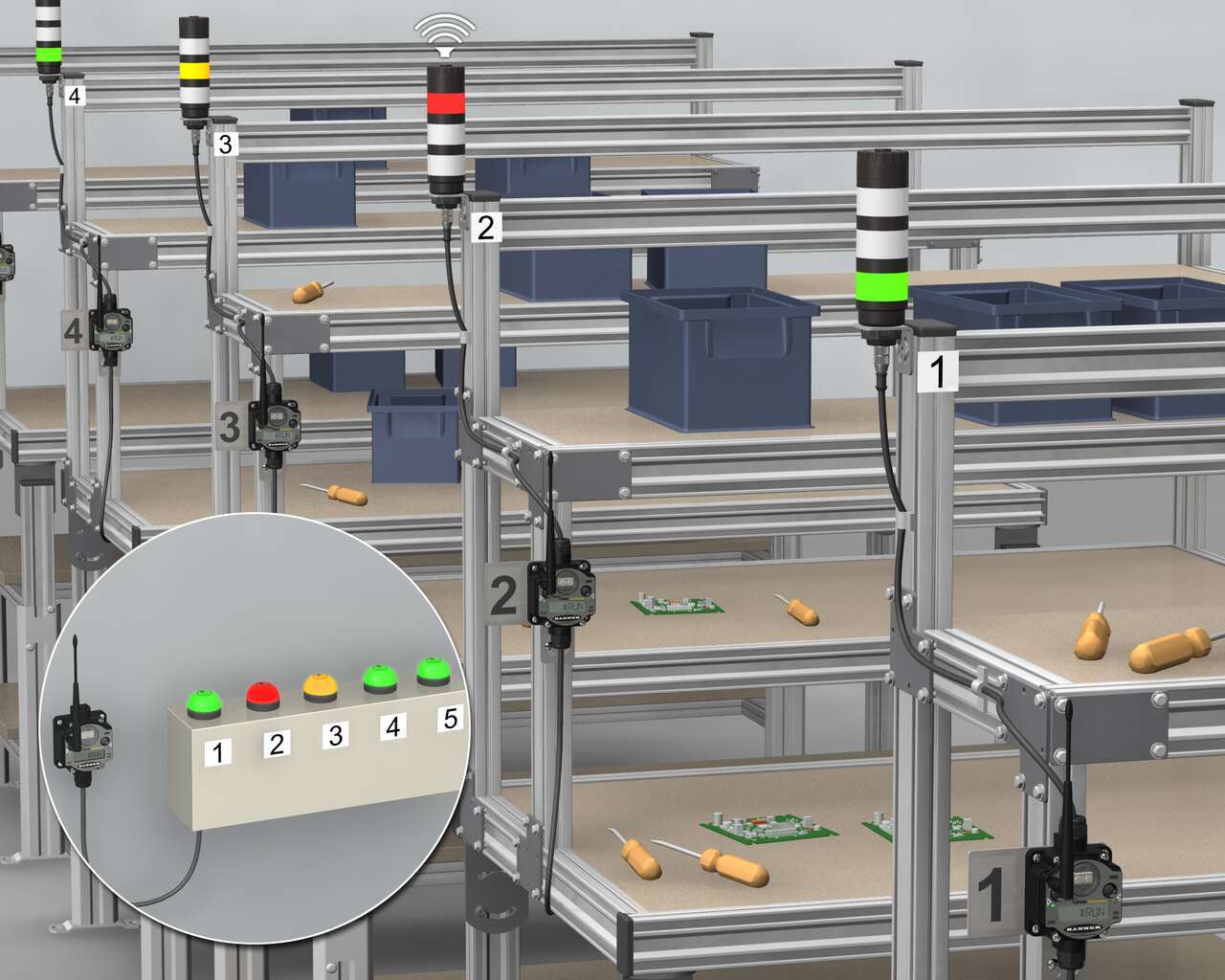

Streamlining Call for Parts or Service

-

Communication in a Busy Manufacturing Site

-

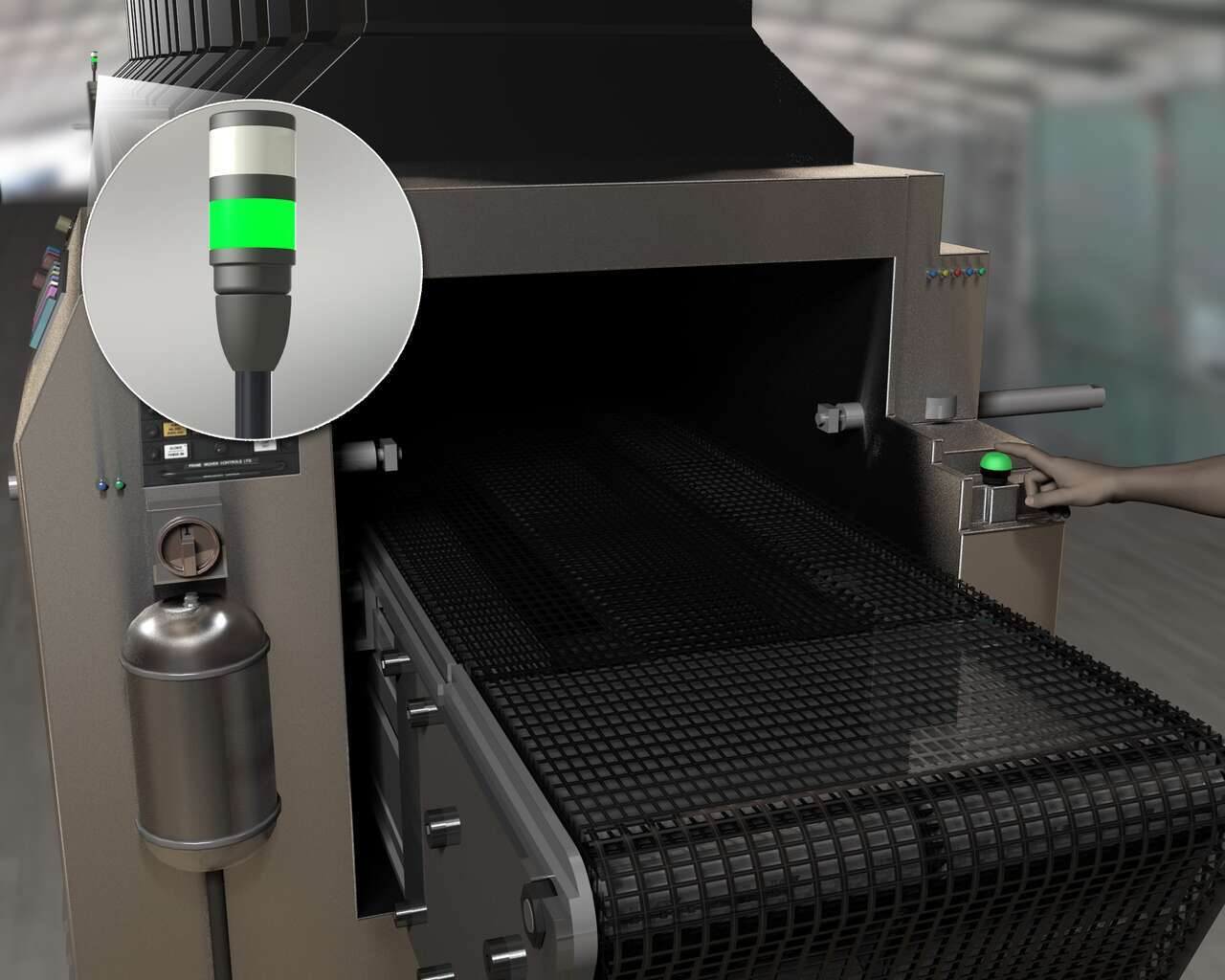

Indicating Pump Panel Status

-

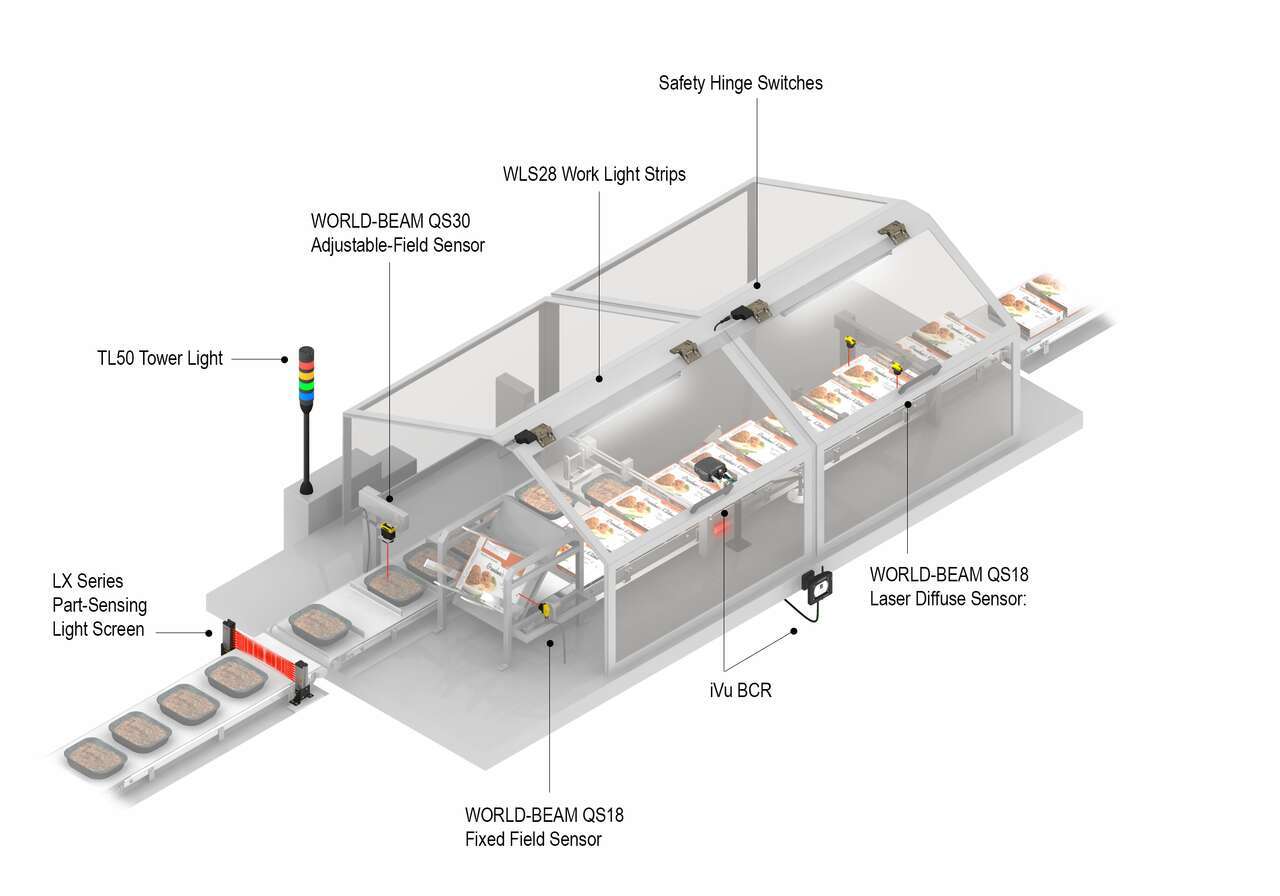

Packaging Frozen Dinners on a Cartoner

-

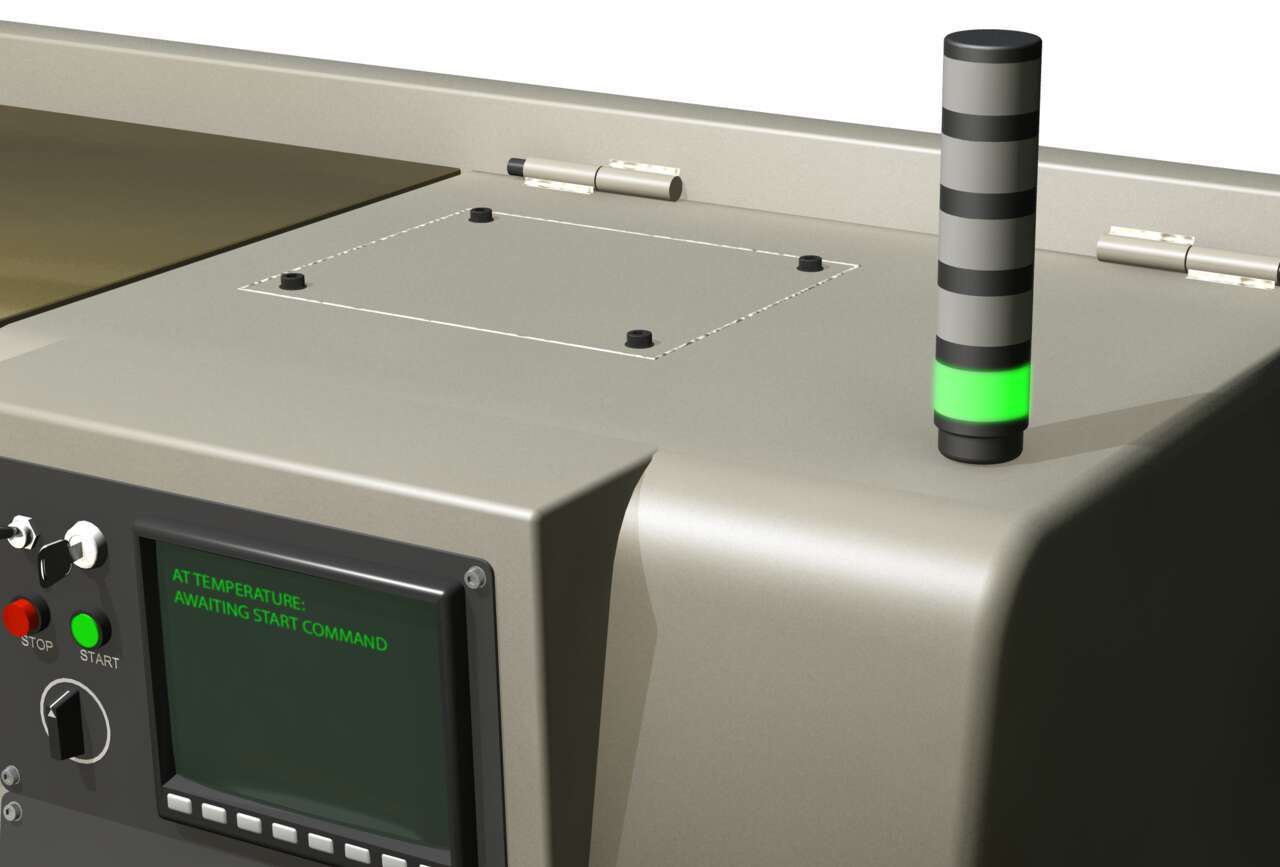

Indicating Machine Status

-

Exit Chute Jam Indication

-

Highly Visible Indication in Extremely Bright Environment

-

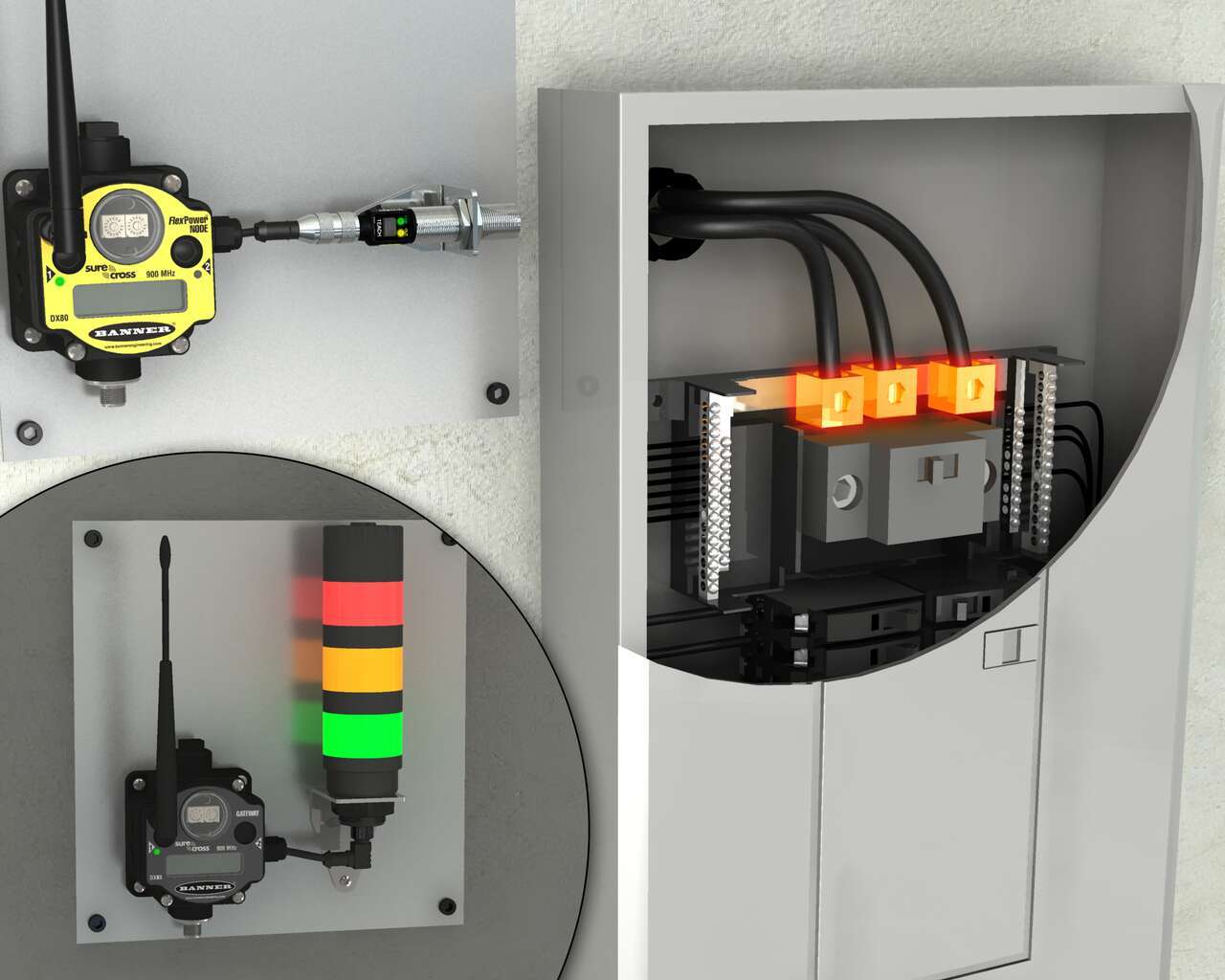

Wireless Machine Monitoring

-

Indicating AGV Call System Status

-

Monitoring Power Use to Avoid Peak Use Charges

-

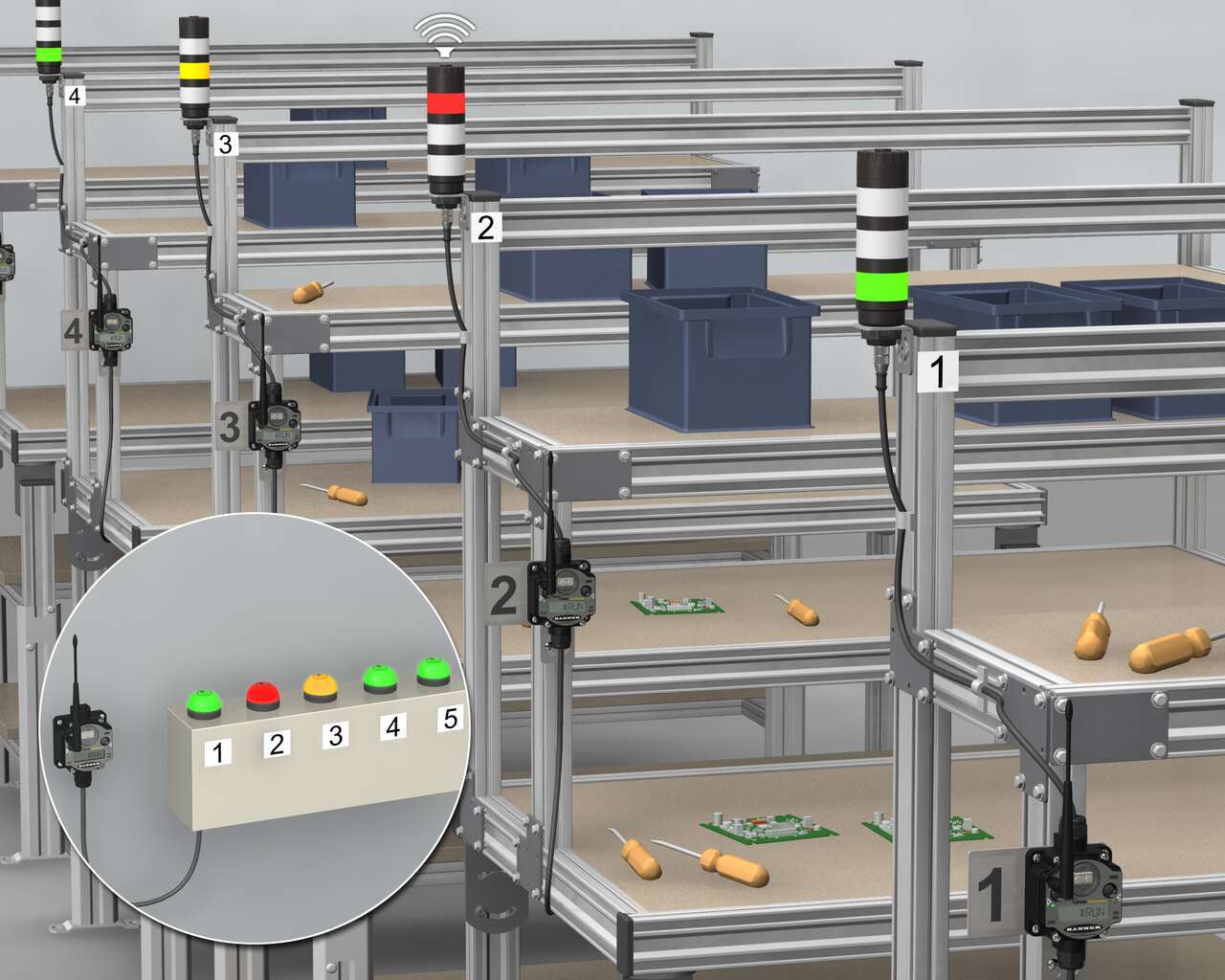

Wireless Call for Parts

Incomplete Checkout

Share Your Checkout Experience

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

Downloads

English Documents

Videos

-

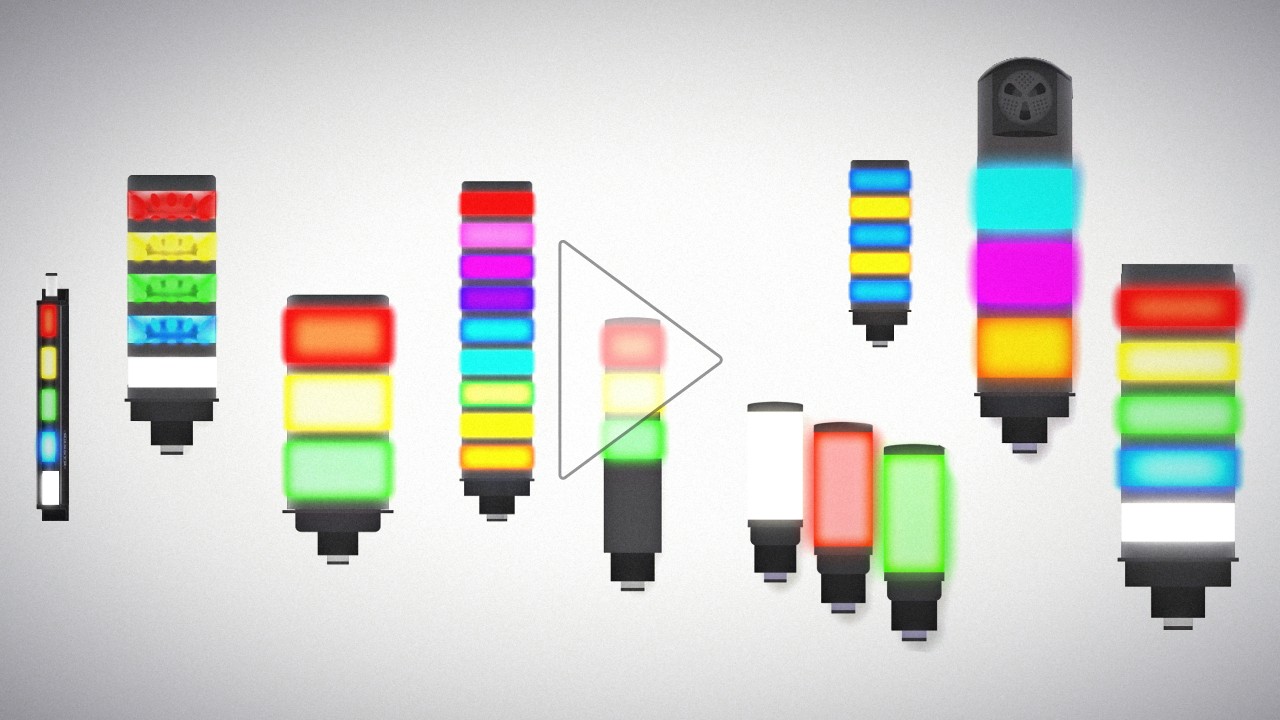

TL50 Tower Light Family

The EZ-LIGHT® TL50 Tower Light Family indicators, including the Standard Tower Light and Beacon Tower Light, are easy to install and provide highly visible operator guidance and equipment status indication.

-

A Complete Family of Tower Lights from Banner Engineering

Banner Engineering offers a complete portfolio of tower lights--for your simplest to your most advanced indication requirements. Watch the video to learn more about our capabilities for machine status indication.

Have a Technical Question?

Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.