Secondary Beverage Packaging Solutions

-

Leading Edge Detection

Leading Edge Detection

Sensors detect the leading edge of pallets, polybags, blister packs, envelopes, tubes, and a wide range of difficult to detect targets.

-

Hot Glue Detection

Hot Glue Detection

T-GAGE M18T Series Temperature Sensors are passive, non-contacting, temperature-based devices designed to detect objects that are hotter or colder than the ambient condition, and then activate an output. In this application, the T-GAGE temperature sensor will detect the presence or absence of hot glue on the flaps of the package. If the hot glue is present, the process will continue and the package will be sealed. If it’s absent, the output will trigger a process to apply the hot glue.

-

Hot Glue Detection on a Package

Hot Glue Detection on a Package

Banner’s T-GAGE M18T temperature sensor is ideal for hot glue verification because it detects the infrared energy an object emits to determine its temperature, sensing from 0⁰C to 300⁰C. In this application, the T-GAGE M18T temperature sensor detects the presence or absence of hot glue on the flaps. If hot glue is present, the package will continue down the manufacturing line;if it is missing, the output will trigger a pusher arm to kick the carton off the conveyor into a bin.

-

Monitor Production I/O for Better Equipment Effectiveness

Monitor Production I/O for Better Equipment Effectiveness

Monitoring production inputs and outputs provides machine operators and managers with critical data about their processes and equipment and can help them identify and resolve problems on the production line more quickly.

-

Measure Throughput and OEE on a Case Sealer

Measure Throughput and OEE on a Case Sealer

Maximize throughput and reduce downtime by harnessing existing data from your equipment.

-

Detecting Clear Bottles to Trigger Shrink Sleeve Labeler

Detecting Clear Bottles to Trigger Shrink Sleeve Labeler

Sensor solutions to detect bottle types with varying frequent in product changovers. High-speed labeler processing 800 bottles per minute, high temps.

-

Detecting Shiny, Unfinished Cans

Detecting Shiny, Unfinished Cans

Sensor solutions to detect small installation areas with multiple deployments on the line. Accurate detection of shiny cans supports smooth product flow.

-

Registration Mark Detection on a Labeler

Registration Mark Detection on a Labeler

Banner Engineering’s R58B Expert registration mark sensor confirms the registration mark’s position on the web. This allows the machine to make minor infeed adjustments to ensure the cut is properly placed and all labels are consistent and complete. If the labels are incorrectly cut they need to be removed from the bottling line creating costly downtime and waste. A quick and easy-to-use sensor is needed to dramatically improve throughput.

-

Loop Control of Clear Plastic

Loop Control of Clear Plastic

The detection of clear plastic is always a challenge. The optical beam of traditional photoelectric sensors will burn through clear material, making sensing results unreliable.

-

Roll Diameter on Labels

Roll Diameter on Labels

In the beverage industry, labels need to be applied to the bottles quickly and without error to keep production levels high. Accurately monitoring the thickness on a spool of labels and controlling the unwinding speed is very important for the process to run smoothly. A solution is needed that can accurately supervise and report the material levels on a spool in order to prevent it from running out during the manufacturing process and delaying production.

-

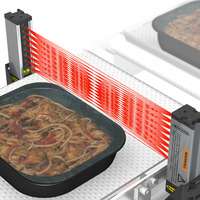

Leading Edge Detection of Packages with a Thin, Flexible Edge

Leading Edge Detection of Packages with a Thin, Flexible Edge

Banner’s LX Series is an economical solution for detecting the leading edge of flat objects, such as the frozen dinner containers. With a web of modulated light, the LX Series part-sensing light screen can detect any item—in any position—passing through the light screen.

-

Refrigerated Breakfast Roll Detection on Multi-Lane Conveyor

Refrigerated Breakfast Roll Detection on Multi-Lane Conveyor

Dark packaging with multiple colors transitions can be difficult to detect with traditional red LED sensors. Banner Engineering’s miniature VS8 photoelectric sensor with blue LED works well with low reflectivity labels to detect refrigerated food packaged in pressurized cans. The small sensors fit into tight spaces and work well for short range applications. The blue LED works with the small spot size to minimize the effects of color transitions on the labels.

-

Date/Lot Code Verification on Food Cartons

Date/Lot Code Verification on Food Cartons

Banner’s rugged PresencePLUS P4 Sealed OMNI vision sensor works well for date/lot codes because it uses Optical Character Verification/OCV inspection to ensure the correct day and lot code are printed legibly. With an IP68-rated housing, the sensor is ideal in food and beverage applications because it can withstand harsh wash-down environments. The P4 OMNI sensor easily locates the region of the carton magazine that needs to be inspected for date/lot codes by verifying the edge of the box. Wi

-

Shrink Sleeve Label Presence and Correct Label Verification

Shrink Sleeve Label Presence and Correct Label Verification

The P4 OMNI vision camera is located immediately after the bottles leave the labeler which assures that the presentation of the label will be in a repeatable manner and therefore can be compared to a stored image for a match. The P4 OMNI is sealed to IP68 and made with nickel plated zinc housing.

-

Date/Lot Code Presence or Absence Detection

Date/Lot Code Presence or Absence Detection

An SLM series slot sensor and an iVu Series vision sensor are used to detect bottles passing on the line and to verify that date/lot codes have been correctly printed onto the bottles.

-

Counting Food Cartons for Correct Packaging

Counting Food Cartons for Correct Packaging

Banner’s WORLD-BEAM QS18LP laser sensor accurately inspects every carton that passes on the conveyor, ensuring the robot is triggered to load cartons into the package. With a visible laser sensing beam, the QS18LP provides precise position control, which is ideal to ensure accurate counting of cartons at a close range. The rugged QS18LP is also ideal for confined spaces and is easily set up along a conveyor for accurate sensing. With highly bright LEDs, operating status is visible from 360⁰.

-

Trigger Sensing on Printer

Trigger Sensing on Printer

In the beverage industry, date/lot codes are mandatory on all products in order to identify when and where a product was manufactured. Finding a solution that can accurately identify the bottle caps and then trigger a machine to print the date/lot codes onto the bottle is required.

.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)