All Beverage Solutions

-

Industrial Refrigeration System Pressure Level Monitoring

Industrial Refrigeration System Pressure Level Monitoring

Performance Series all-in-one wireless pressure sensors make it easy to monitor pressure levels in large and complex systems from any network-enabled location.

-

Detecting Bottles in Washdown: Glass & PET Plastic

Detecting Bottles in Washdown: Glass & PET Plastic

Detect clear glass and PET plastic bottles with various shapes and sizes. Washdown environment, IP69K ratings.

-

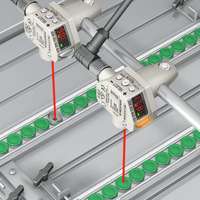

Reliable Detection of Transparent Bottles on Conveyor

Reliable Detection of Transparent Bottles on Conveyor

A machinery company needed a sensor able to consistently detect clear PET bottles at multiple points.

-

In-Line Accumulation on Single Filer

In-Line Accumulation on Single Filer

The Q5X laser sensor reliably detects when the staging area is clear of bottles and the system is ready for the next layer of containers, despite the transparency of the bottles and unstable signal.

-

Detecting PET Bottles to Regulate Product Flow

Detecting PET Bottles to Regulate Product Flow

Sensor solutions to detect translucent bottles in a range of shapes, sizes, colors and contours in a high-speed air conveyance system, identifying gaps.

-

Counting Multicolored Reflective Packages on a Conveyor

Counting Multicolored Reflective Packages on a Conveyor

Sensor solutions to verify packaging and count on conveyor. Foil and film packaging such as tea bags, multiple colors on packaging material.

-

Clear Glass Jar Detection for Food and Beverage Splash Zone

Clear Glass Jar Detection for Food and Beverage Splash Zone

Sensor solutions to detect clear glass jars to be filled with food in a strict sanitary environment where frequent, high-pressure washdowns and IP69K ratings.

-

Detecting Clear Bottles to Trigger Shrink Sleeve Labeler

Detecting Clear Bottles to Trigger Shrink Sleeve Labeler

Sensor solutions to detect bottle types with varying frequent in product changovers. High-speed labeler processing 800 bottles per minute, high temps.

-

Detecting Transparent Bottles in a Washdown Environment

Detecting Transparent Bottles in a Washdown Environment

Sensor solutions to detect accumulations to regulate line pressure where bottles vary in size, shape, color, and translucence and there is not a reflector.

-

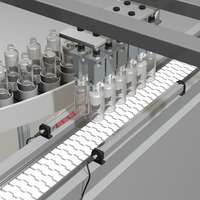

Accurate Counting of Transparent Pharmaceutical Bottles

Accurate Counting of Transparent Pharmaceutical Bottles

Sensor solutions to count translucent and reflective glass vials in high-speed processes requiring quick response times and challenging light conditions.

-

Monitoring Flow of Transparent Plastic Bottles on a Conveyor

Monitoring Flow of Transparent Plastic Bottles on a Conveyor

Sensor solutions to monitor a conveyor to ensure there are no stuck bottles when bottles are clear plastic in a large sensing area.

-

Detecting and Indicating the Presence of a Tipped Bottle

Detecting and Indicating the Presence of a Tipped Bottle

Sensor solutions to detect translucent bottles filled with clear liquid with a long bottling line with numerous areas to monitor.

-

Color Sensor Automates Sorting of Clear and Tinted Bottles

Color Sensor Automates Sorting of Clear and Tinted Bottles

Sensor solutions to detect plastic bottles varying in color and translucence where a high-speed system requires fast response times. Accurate sorting.

-

Detecting Tipped-Over Bottles on a High-Speed Bottling Line

Detecting Tipped-Over Bottles on a High-Speed Bottling Line

Detect translucent bottles varying by size, shape, color, and faceting. Large scale system of monitoring in multiple locations, quick clearance of tipped bottle.

-

Detecting Shiny, Unfinished Cans

Detecting Shiny, Unfinished Cans

Sensor solutions to detect small installation areas with multiple deployments on the line. Accurate detection of shiny cans supports smooth product flow.

-

Clear Container Detection in a Clean-in-Place Rotary Filler

Clear Container Detection in a Clean-in-Place Rotary Filler

Sensor solutions to detect bottle types vary in size, shape, color, translucence, and material. Equipment is regularly exposed to harsh washdown.

-

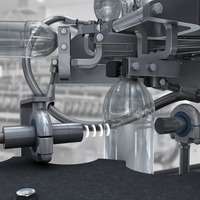

Hygienic Sensor Detects Variety of Bottle Types on a Rinser

Hygienic Sensor Detects Variety of Bottle Types on a Rinser

Sensor solutions to detect bottle types vary by size, shape, color, contours, and translucence on a rinser where equipment is regularly exposed to washdowns.

-

Detecting Registration Marks on Labels

Detecting Registration Marks on Labels

Banner’s R58 high-speed, low-contrast expert registration sensor detects subtle registration marks on the labels as they pass at high speed—ensuring the label is cut at precisely the right moment for correct label placement. To accommodate frequent changeovers, the sensor is designed with LED color options—which automatically change depending which color best optimizes contrast.

-

Registration Mark Detection on a Labeler

Registration Mark Detection on a Labeler

Banner Engineering’s R58B Expert registration mark sensor confirms the registration mark’s position on the web. This allows the machine to make minor infeed adjustments to ensure the cut is properly placed and all labels are consistent and complete. If the labels are incorrectly cut they need to be removed from the bottling line creating costly downtime and waste. A quick and easy-to-use sensor is needed to dramatically improve throughput.

-

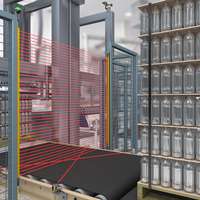

Safety at Palletizer Station with Sticky Liquids Present

Safety at Palletizer Station with Sticky Liquids Present

Safeguarding palletizer machines can be difficult because bottles are under a lot of pressure and can contain corrosive liquids such as soda or juice. Hygienic enclosures protect light curtains from corrosive liquids, meet sanitary requirements, and do not affect the performance of the sensor.

-

Safety Light Screens Guard Operators from Sweep Bar

Safety Light Screens Guard Operators from Sweep Bar

The EZ-Screen LPs Type 4 Safety Light screens guard the operators of a depalletizer from the motion of the sweep bar. To guard individuals from the sweep bar, a 14mm resolution between beams prevents access and injury. If an individual or item breaks the beams of the EZ-Screen, the sweeping motion will stop to prevent harm. The low-profile design of the light curtains allows for easy installation along a machine and does not require a PC or additional equipment for setup.

-

Depalletizer Guarding with Muting Pair

Depalletizer Guarding with Muting Pair

A company needed a way to safe-guard the area where pallets of empty bottles or cans enter into the depalletizer. Learn how Banner Engineering's XS26-2 Safety Controller with EZ-Screen safety light and LS-S safety light curtains helped maintain a continuous flow of pallets while protecting hazardous areas of a machine from workers.

-

Safeguarding the Palletizer and Stretch Wrapper

Safeguarding the Palletizer and Stretch Wrapper

Safeguarding areas around the palletizers and stretch wrappers can prove to be difficult because it involves multiple hazards. A scalable safety controller can help manage hazards related to the palletizer and stretch wrapper while ensuring efficient safeguarding processes.

-

Barcode Reading on Pallet

Barcode Reading on Pallet

Banner’s TCNM linear barcode scanner is recommended for scanning and validating the barcodes. It is able to decode over a dozen commonly used linear barcode symbols helping maintain an efficient flow of bottles along the production line. Utilizing the TCNM linear sensor allows for an automated way to confirm the correct product in real time.

-

Barcode Confirmation on Pallet

Barcode Confirmation on Pallet

Shipping containers are often labeled with barcodes in order to more easily identify which product is present and ready to be shipped. A sensing solution needs to be present to confirm that the final, shrink-wrapped product is labeled correctly and matches the content inside.

-

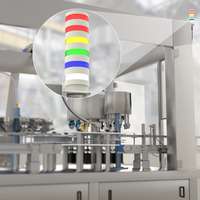

Dynamic Maintenance Indication on a Beverage Line

Dynamic Maintenance Indication on a Beverage Line

TL50 Pro tower lights clearly informs operators that maintenance procedures are in progress with advanced action mode animation.

-

Liquid in Container Detection

Liquid in Container Detection

Banner combined the technology of WORLD-BEAM QS30 opposed mode sensors, which provide high excess gain, with a 1450 nm infrared sensing beam—specially tuned to an absorption band of water, to create the QS30H2O Water Sensor. In this application, the powerful sensing beam of the QS30H2O will burn through the opaque plastic of the container. At 1450 nm, water absorbs 1,000 times the energy of alternative wavelengths, preventing the beam from burning through the liquid within the container.

-

Level Monitoring for Washdown Environments

Level Monitoring for Washdown Environments

Banner’s U-Gage QT50U ultrasonic sensor excels at the most challenging level applications, bouncing sound off any solid surface—even those that may vary in consistency or contrast. The sensor is available with a Teflon-coated transducer cover, making it resistant to harsh chemicals and suitable for the food and beverage industry. Ultrasonic sensors are able to provide accurate monitoring of pump-controlled tanks by sending a continuous signal to measure the current tank depth.

-

Level Monitoring On Rotary Filler System

Level Monitoring On Rotary Filler System

Banner’s Sure Cross wireless system can easily transmit temperature, pressure and fill levels to a local PLCs. The wireless system will seamlessly alert operators if bottling is occurring below the desired fill level. This helps prevent errors and leads to greater consistency in bottled beverages. Consistent fill levels mean no recalls—and no wasted products. Using a wireless system also eliminates the need for slip rings on the rotary filler, which in turn reduces maintenance costs.

-

Remote Fill Level Indicator

Remote Fill Level Indicator

A brew pub uses EZ-LIGHT indicator lights as a remote display of the status of the levels in the brew tanks. The indicators are connected to ultrasonic sensors within the tanks that cannot be monitored easily.

-

Tank Level, Pressure, and Temperature Monitoring

Tank Level, Pressure, and Temperature Monitoring

To wirelessly monitor and report level, pressure, and temperatures in the rotary fillers, each rotary filler was equipped with a FlexPower Node and DX81P6 6-pack battery supply. The FlexPower Node had two 0–20 mA analog inputs and one thermistor input while the battery pack supplied power to the Node and sensors for more than a year. A level probe, pressure transmitter, and thermistor (not supplied by Banner) were connected to the FlexPower Nodes and installed in the rotary tanks.

-

Non-Contact Fill Level Verification

Non-Contact Fill Level Verification

Banner’s QS30H2O sensor is a specialized sensor developed to address challenges with sensing the presence of water and water-based liquids. The QS30H2O operates in a through beam sensing mode and the emitter uses a wavelength that is tuned to not pass through water. The high excess gain of the sensor makes it powerful enough to see through an assortment of plastic and glass containers. Two pairs of sensors can be utilized to determine that the fill level has met minimum but is not overfilled and wasting product. Apertures can be placed on the receiver end to minimize the beam pattern and increase accuracy of the application. This ensures products that do not meet fill level criteria are not processed or shipped.

-

Tank Level Monitoring

Tank Level Monitoring

Using K50U ultrasonic sensors and Q45U wireless nodes paired to a DXM100 wireless controller, we can develop a wireless monitoring system for multiple tank level measurements that is easy to set up, interpret the results, and monitor locally through a cloud-based system.

-

Clear Material Loop Control

Clear Material Loop Control

Banner’s T30UX ultrasonic sensor is the perfect sensor for detecting clear material for loop control because it uses sound rather than light, which makes it more accurate and cost-effective for this specific application. Although the material is clear, it presents a solid surface for an ultrasonic sensor to bounce a sound wave. The T30UX has a more accurate transducer, a smaller dead zone and minimum distance compared to other sensors that can be used for clear material detection.

-

Roll Diameter on Labels

Roll Diameter on Labels

In the beverage industry, labels need to be applied to the bottles quickly and without error to keep production levels high. Accurately monitoring the thickness on a spool of labels and controlling the unwinding speed is very important for the process to run smoothly. A solution is needed that can accurately supervise and report the material levels on a spool in order to prevent it from running out during the manufacturing process and delaying production.

-

Cap Orientation Verification

Cap Orientation Verification

Banner’s Q4X laser sensor, made of 316L grade stainless steel, is very suitable for pharmaceutical environments and other aseptic filling areas. The Q4X has a sensing range of 25 to 300 mm, precise beam spot size and can effectively detect the orientation of caps as they exit a feeder bowl. If any caps are upside down, the Q4X will detect a height difference and reject the cap.

-

Cap Sorter Detection

Cap Sorter Detection

Banner’s R55F fiber optic sensors have the capability to detect the presence of caps regardless of their color or size – a clear advantage in an industry that has a wide variety of bottle caps and frequent line changes. In this type of application, the fiber optic sensors are used to recognize long pauses between the caps which would then signal a jam to the operators of the machine. The fibers are compact and can be easily mounted in confined and typically inaccessible spaces.

-

Date/Lot Code Verification on Food Cartons

Date/Lot Code Verification on Food Cartons

Banner’s rugged PresencePLUS P4 Sealed OMNI vision sensor works well for date/lot codes because it uses Optical Character Verification/OCV inspection to ensure the correct day and lot code are printed legibly. With an IP68-rated housing, the sensor is ideal in food and beverage applications because it can withstand harsh wash-down environments. The P4 OMNI sensor easily locates the region of the carton magazine that needs to be inspected for date/lot codes by verifying the edge of the box. Wi

-

Identifying Presence and Height of a Bottle Cap

Identifying Presence and Height of a Bottle Cap

The iVu Plus Gen 2 vision system, paired with a Q4X and LEDRB backlight, offer a solution that will provide dependable results.

-

Detection of Cap Orientation

Detection of Cap Orientation

The Banner Q3X laser diffuse sensor is ideal for applications that require orientation detection with small contrast differences.

-

Date/Lot Code Inspection

Date/Lot Code Inspection

To verify each package has a date/lot code printed on it, an iVu Series sensor is configured for a Match inspection. An image of the date/lot code is captured. When the inspection is running, if the sensor detects a package without the date/lot code the sensor sends a fail output to the line, and the product is rejected.

-

Label Inspection in a Wet Environment

Label Inspection in a Wet Environment

A sealed PresencePLUS Pro COLOR vision sensor is encased in an enclosure that protects it from damage in a wet environment. The Pro checks for label presence and placement.

-

Small Part Inspection in Tough Location

Small Part Inspection in Tough Location

Banner Engineering’s iVu vision sensor inspects presence vent tubes and spreader washers on a busy bottling line. It uses a 50 mm C-Mount lens to extend the working range of the sensor to avoid contact with spray and liquids.

-

Detecting Tamper-Evident Band Position and Presence

Detecting Tamper-Evident Band Position and Presence

Banner iVu TG vision sensor with multi-point inspections is ideal for detecting and evaluating the position of tamper-evident bands. In this application, the band should be positioned around both the cap and the neck of a bottle. A seal positioned too high, too low, or completely missing would be considered unacceptable. With multi-point inspection, the iVu TG vision sensor can simultaneously detect missing and poorly positioned bands.

-

Correct Label Verification

Correct Label Verification

An iVu TG Image Sensor works well for label verification because it comes with four sensor types, including a match sensor. The match sensor determines whether a pattern on a label matches a reference pattern and if it is correctly oriented. With just the touch of a button—or remotely through a PLC—users can easily teach the iVu image sensor to recognize and match the correct label pattern, requiring no image processing expertise.

-

Shrink Sleeve Label Presence and Correct Label Verification

Shrink Sleeve Label Presence and Correct Label Verification

The P4 OMNI vision camera is located immediately after the bottles leave the labeler which assures that the presentation of the label will be in a repeatable manner and therefore can be compared to a stored image for a match. The P4 OMNI is sealed to IP68 and made with nickel plated zinc housing.

-

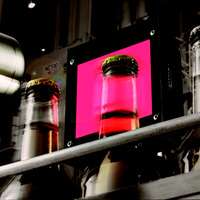

High-Speed Bottle Inspection with PresencePlus

High-Speed Bottle Inspection with PresencePlus

To rapidly verify that beer bottles are filled to the correct level and that caps are correctly aligned, a high-speed PresencePLUS P4 vision sensor locates the bottle and verifies the fill level and cap placement. This helps eliminate the need for multiple sensors, while accurately detecting the presence of caps and monitoring fill level. The red backlight provides a strong contrast to the bottles, amplifying the bottle features for easy detection.

-

Cap Inspection in Confined Areas

Cap Inspection in Confined Areas

The rugged PW12-rated World-Beam Q12 sensor inspects bottle closures using fixed-field technology to ignore cap color changes. With many types of bottles and product coming down the line, it is important for the sensor to ignore the size of the cap whether it is 25 or 50 mm. Using the same fixed-field technology, the Q12 easily ignores color and size changes in caps, while detecting whether or not a cap is present.

-

Bottle Cap Inspection

Bottle Cap Inspection

After bottles are filled and capped, they are conveyed under the WORLD-BEAM Q12 sensor at close range, before they are packed in cartons. The Q12 sensor, operating in fixed-field mode, detects missing or misaligned caps—regardless of color—and triggers the line to reject uncapped bottles. Because the sensor uses fixed-field mode, it responds when a cap is not at the exact distance from the sensor that it should be.

-

Code Inspection on Clear Bottles

Code Inspection on Clear Bottles

A PresencePLUS OMNI inspects the neck of a clear plastic bottle to verify that the date/lot code has been imprinted on the bottle. It also confirms that the cap is properly applied and that the bottle's fill level is within the acceptable range.

-

Labeling Detection

Labeling Detection

In an application with limited space, the WORLD-BEAM Q20 sensor is easily positioned to verify the presence of a label before it is applied to the product.

-

Date/Lot Code Presence or Absence Detection

Date/Lot Code Presence or Absence Detection

An SLM series slot sensor and an iVu Series vision sensor are used to detect bottles passing on the line and to verify that date/lot codes have been correctly printed onto the bottles.

-

Inspecting Bottles for Cap Presence and Correct Color

Inspecting Bottles for Cap Presence and Correct Color

To ensure that product quality standards are met and that product appearance is consistent with the brand, the company must inspect each bottle to ensure that the right bottle cap is present and properly seated.

-

Vent Tube Presence on Filler

Vent Tube Presence on Filler

A high-volume brewery needed a solution capable of detecting spreader washers on the vent tubes as well as loose or missing tubes. However, the movement of the rotary filler and the wet washdown environment made close proximity deployments difficult and the range required for a remote solution could compromise inspection reliability.

-

Shrink Sleeve Labeling at High Speeds

Shrink Sleeve Labeling at High Speeds

A leading manufacturer of labeling equipment offers high-speed shrink sleeve label applicators designed to process 800 bottles per minute. To maximize the machine’s performance potential, the company wanted to install sensors capable of consistent detection and output for high-speed bottling.

-

Juice Carton Detection

Juice Carton Detection

As cartons of juice pass on a conveyor, the WORLD-BEAM QS30 sensor in fixed-field mode detects the presence or absence of a carton, regardless of color and pattern.

-

Fill Level Verification of Water Bottles

Fill Level Verification of Water Bottles

Banner’s QS30H2O sensor is a specialized sensor developed to address challenges with optically sensing the presence of water and water-based liquids. The QS30H2O operates in a through beam sensing mode and the emitter has a unique LED with a 1450 wavelength. The 1450 wavelength is easily attenuated by water.

-

Parts Detection in a Feeder Bowl

Parts Detection in a Feeder Bowl

In this illustration, caps have been loaded into a feeder bowl which consistently orientates the parts to be positioned for bottle application later in the process. The Banner QS30AF an ideal sensing solution for this application, positioned to monitor the supply level of the caps as they move out of the bowl.

-

Slip Ring Replacement with Wireless Solutions

Slip Ring Replacement with Wireless Solutions

Slip rings are subject to constant movement which in turn leads to continuous maintenance in order to avoid degradation of the rotating electrical connection caused by normal wear and debris. Slip ring failure bring production to a halt, resulting in unexpected and costly downtime. The DX80 wireless radios provide a non-contact solution for transmitting the sensor signals from inside the filler bowl to the control panel. The wireless node located on the rotary filler can be battery powered thus providing power to the sensors for a wire-free installation. The DX80 wireless solution eliminates the need for slip rings, helping to decrease downtime and maintenance.

-

Soda Can Flow Control

Soda Can Flow Control

The Q60 background-suppression sensor detects when the flow of cans has stopped and signals the machine control that manages processes further down the line. The timing delay feature prevents the Q60 from sending the signal when it senses a small gap between cans.

-

Rope Pull on Conveyors

Rope Pull on Conveyors

Banner’s RP-LS42F rope pull switches run along the length of a conveyor so the operator can grab and pull it from anywhere to immediately stop the conveyor. Spans of rope range from 6 m to 100 m, providing the flexibility to safeguard long or short conveyors. The RP-LS42 switches are compact and have a variety of accessories available for easy installation and rope tension. They are also made with heavy-impact thermoplastic housing for use in demanding industrial settings.

-

Bottle Label Verification

Bottle Label Verification

Banner’s Q3X versatile, rugged laser contrast sensor including background suppression is ideal for contrast applications where there is also a fixed background that needs to be ignored. In this application, the Q3X background suppression sensor detects the contrast difference between a bottle with and without a label for reliable label detection. With a range up to 50 mm, the Q3X has a tight laser spot able to detect a small change in contrast reliably.

-

Trigger Sensing on Printer

Trigger Sensing on Printer

In the beverage industry, date/lot codes are mandatory on all products in order to identify when and where a product was manufactured. Finding a solution that can accurately identify the bottle caps and then trigger a machine to print the date/lot codes onto the bottle is required.

-

Enunciation of Safety Conditions with Visual Indication

Enunciation of Safety Conditions with Visual Indication

In order to maintain an efficient manufacturing line in the beverage industry, immediate notification of any safety issues is fundamental. Using visual and audible indication to identify safety concerns helps workers quickly find and fix the errors – returning the system to its normal operating state in a timely fashion.