Beverage: End of Line Packaging

The end of the line is the final phase of product packaging. Conveyors, palletizers, forklifts and personnel converge in this area and activity is near constant. The flow of cases into this area and the flow of assembled pallets leaving the area must be closely regulated to prevent line slowdowns and stoppages. Safety measures must also be in place to protect personnel from accident or injury.

Our industry knowledge and expertise in sensors, safety control, LED lighting and indicators allow us to offer solutions that solve many of the most difficult applications in the final packaging area. From sensors capable of detecting targets with vibrant graphics, clear, shiny packaging to offering the most comprehensive collection of safety products in the industry, including heavy-duty safety light curtains and expandable safety controllers, you can rely on products from Banner to improve your packaging processes and address all your machine safeguarding requirements.

End-of-Line Beverage Applications

View Applications by Machine Type

Featured Applications

Reading Multiple 1D and 2D Barcodes

Barcode position can change with the location of each box on a conveyor and the height of the boxes can vary. An ABR 7000 barcode reader decodes multiple 1D and 2D barcodes over a large area in a single inspection, regardless of position or orientation.

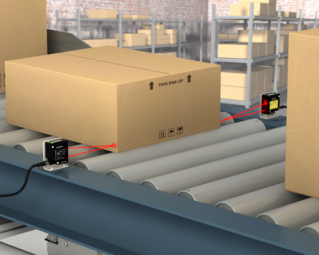

Carton Profiling

Cartons moving on a conveyor pass between two LE550 laser sensors, measuring the width in order to sort cartons properly. The LE550 sensors are an economic solution for carton profiling. The analog output sends a signal to the PLC to deliver the carton to the correct storage location. Banner’s LE550 provides repeatability and accuracy while measuring the height, length and width of cartons. The laser sensors have an intuitive user interface, making it easy to adjust settings.

Barcode Confirmation on Pallet

Shipping containers are often labeled with barcodes in order to more easily identify which product is present and ready to be shipped. A sensing solution needs to be present to confirm that the final, shrink-wrapped product is labeled correctly and matches the content inside.

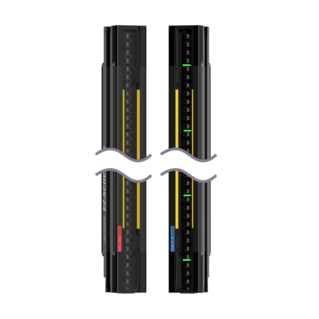

Enunciation of Safety Conditions with Visual Indication

In order to maintain an efficient manufacturing line in the beverage industry, immediate notification of any safety issues is fundamental. Using visual and audible indication to identify safety concerns helps workers quickly find and fix the errors – returning the system to its normal operating state in a timely fashion.

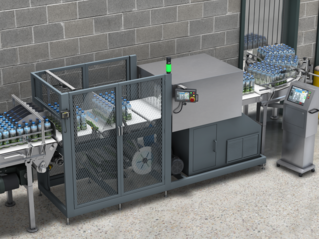

Safeguarding the Palletizer and Stretch Wrapper

Safeguarding areas around the palletizers and stretch wrappers can prove to be difficult because it involves multiple hazards. A scalable safety controller can help manage hazards related to the palletizer and stretch wrapper while ensuring efficient safeguarding processes.

Barcode Reading

ABR Series barcode readers can be used to solve track and trace applications, offering increased resolution to read smaller codes, over a larger target area, and at greater distances. Polarization is now available in both 1.3 MP and 2 MP ABR 7000 models for improved performance on targets with reflective surfaces or where glare is present. Our highest resolution camera, the VE is also available in only-barcode reading models, as well as the original vision camera-only model. This makes our VE series is the highest-resolution barcode reader in our portfolio, designed to better solve complex applications.

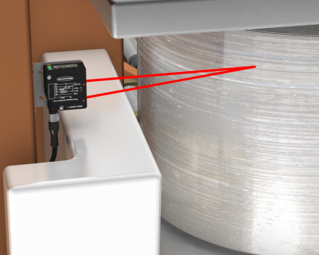

Plastic Roll Diameter Measurement

Banner’s LE550 is factory configured with a range of 100 to 1000 mm and can start measuring immediately. If the range needs to be adjusted, the laser sensor has an intuitive user interface with a two-line, eight-character display, making it easy to automatically or manually adjust settings. The LE550 provides repeatability and accuracy across challenging targets, from metal to black rubber, allows for reliable measurement of the shrink wrap.

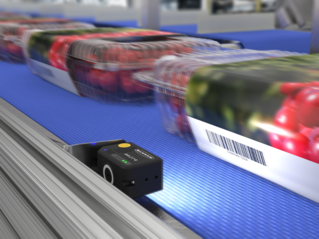

Tracking Products through Packaging

Barcodes used to track packaged produce through the supply chain contain important product information that must be verified at multiple points during packaging. An ABR 3000 barcode reader ensures that the barcode on each package is present and correct.

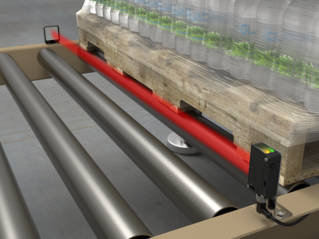

Leading Edge Detection

Sensors detect the leading edge of pallets, polybags, blister packs, envelopes, tubes, and a wide range of difficult to detect targets.

Robotic Palletizer Safeguarding

Banner’s XS26-2 is a flexible, easy-to-use safety controller with an intuitive programming environment, with the capacity to handle current machine processes and the flexibility to add up to eight I/O expansion modules as machine automation grows or changes. A broad spectrum of safety devices are supported, allowing for complex applications to be configured and downloaded to the controller in a minimal amount of time for efficient machine commissioning.