All Electronics Solutions

-

Environmental Monitoring inside a Machine Control Panel

Environmental Monitoring inside a Machine Control Panel

Identify small problems before they become major issues that impact machine performance and uptime.

-

Easy-to-See Status Indication in Close Proximity to Staff

Easy-to-See Status Indication in Close Proximity to Staff

To optimize efficiency and output, the progress of multiple FOUPs in single wafer deposition machine must be closely monitored. Staff work in close proximity to these machines and prolonged exposure to bright light from tower lights can cause eye strain, leading to physical and mental fatigue. Keep reading to learn how TL30 Basic tower lights solve this application.

-

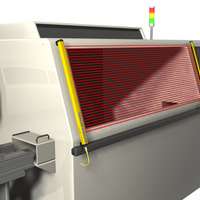

Lower-Risk Machine Guarding: Carousel

Lower-Risk Machine Guarding: Carousel

The Type 2 EZ-SCREEN safety light screen protects hands and fingers from being bumped, bruised, or pinched by the moving parts of a carousel.

-

Lower-Risk Machine Guarding: Chip Shooter

Lower-Risk Machine Guarding: Chip Shooter

The Type 2 EZ-SCREEN safety light screen guards the opening to a chip shooter, which has moving parts that can cause painful but usually temporary injuries.

-

Safety Control on Small Machines

Safety Control on Small Machines

An SC10 Series safety controller replaces the functionality of three safety relays with one compact, cost-effective device offering intuitive operation and advanced capabilities.

-

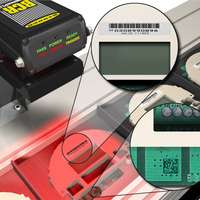

Industrial Barcode Verification on a Cell Phone Component

Industrial Barcode Verification on a Cell Phone Component

The PresencePLUS P4 BCR industrial barcode scanner reads and verifies the small 2D bar code affixed to a component of a cell phone.

-

Verification of Two Barcodes on a Part

Verification of Two Barcodes on a Part

A part is tracked using both a linear and a 2-dimensional barcode. The high-resolution PresencePLUS P4 BCR 1.3 reads both types simultaneously to verify that they are correct.

-

High-Performance ABR Reader for DPM Codes on Electronics

High-Performance ABR Reader for DPM Codes on Electronics

On electronic assembly lines, reliably identifying and reading small 2D Direct Part Marking (DPM) codes is essential. These information-dense codes track data at the component level, such as serial number and date of production.

-

Multiproduct Light-Guided Assembly Station

Multiproduct Light-Guided Assembly Station

PTL110 pick-to-light devices on a multiproduct assembly station are a highly effective way to prevent errors and speed up build time. The optical sensors on PTL devices detect hands as they pass by, confirming that a pick was made.

-

Illumination and Indication for PCB Assembly

Illumination and Indication for PCB Assembly

Placing WLS27 Multicolor LED Strip Lights with EZ-STATUS above PCB assembly machines provides area lighting and status indication with one rugged and versatile light. Any changes in machine status cause the WLS27 to switch from illumination to indication and cover the entire machine with the corresponding color. This type of indication allows operators to focus on the task at hand without missing changes in machine status.

-

Monitor Fill Level of Liquid in Mobile Drum

Monitor Fill Level of Liquid in Mobile Drum

The K50U wireless ultrasonic sensor was designed specifically as a non-contact level monitoring solution. Monitoring the levels of epoxy in drums during refill alerts staff of potential overflows before they become a problem.

-

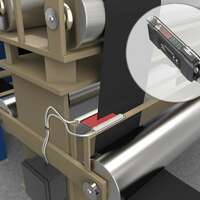

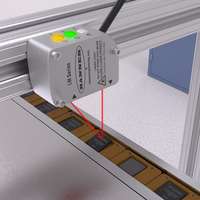

Edge Guiding for Battery Manufacturing

Edge Guiding for Battery Manufacturing

The DF-G3 fiber optic amplifier, used with plastic fibers, is a precise solution for edge guiding during lithium-ion battery assembly. Proper edge guiding reduces the amount of wasted product.

-

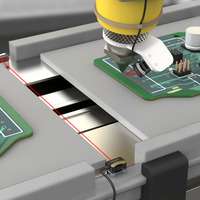

Real-Time Adhesive Detection in PCB Assembly

Real-Time Adhesive Detection in PCB Assembly

Banner Engineering’s miniature VS8 sensor fits atop a glue gun to accurately detect the presence of adhesive as it is being applied. The VS8 is taught the distance between glue gun and PCB and can detect the very small height distance after the adhesive gets applied and recognize if there are any gaps or bubbles. The miniature sensors fit into tight spaces common in electronics assembly.

-

Error-Proofing Loading of IC Chips into Pocket Tape

Error-Proofing Loading of IC Chips into Pocket Tape

• Confirm presence and orientation of IC chips • Sensor performs multiple functions at once • Cost savings and versatility

-

Electronic Marking Verification

Electronic Marking Verification

The solution uses an iVu Series sensor configured for a Match inspection. A reference "good" identifier is taught into the sensor. In service on the production line, the sensor detects when a component does not have the correct identifier, and sends a fail output to the line, and the part is rejected.

-

Adhesive Bead Detection

Adhesive Bead Detection

The DF-GI amplifier, with the fiber optic sensing tip positioned near where the robot applies the adhesive, verifies that adhesive is applied to the IC chips. Opposed pairs of VS2 sensors detect when the level of filled wafer trays exceeds a preset height.

-

Detecting Integrated Circuit Chip Presence and Orientation

Detecting Integrated Circuit Chip Presence and Orientation

A precise measurement solution is required to ensure that integrated circuit (IC) chips are present and oriented correctly in nests. Learn how the LM laser measurement sensor solves this application.

-

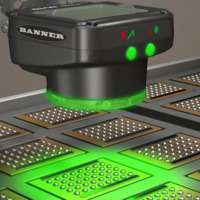

Solder Ball Inspection

Solder Ball Inspection

To verify each integrated circuit, this application uses an iVu Series sensor configured for an Area with Motion application. If the sensor detects a part with missing or damaged solder balls, or if it detects any foreign material, the sensor sends a fail output to the line, and the part is rejected.

-

Hard Disk Detection

Hard Disk Detection

Because disk surfaces are shiny, many sensors have difficulty detecting whether a hard disk is properly seated in a hard drive. Banner Engineering’s Q3X and Q4X sensors are designed to detect shiny surfaces with a wide variety of colors, textures, and materials.

-

Part Flaw Detection

Part Flaw Detection

To verify an electronic component like that shown, an image of a good part was captured using an iVu Series sensor configured for a Match inspection. If the sensor detects a part with a bent or missing connector, or if the part is wrong side up, the sensor sends a fail output to the line, and the part is rejected.

-

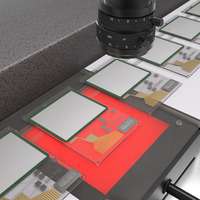

Fine Detail Inspection of Mobile Electronic Devices

Fine Detail Inspection of Mobile Electronic Devices

Cell phones and other mobile electronics have densely populated components on their printed circuit boards. A VE Smart Camera is used to capture all the fine details and ensure that all components are present and placed correctly. Using a camera eliminates the risk of human error and prevents malfunctions and recalls.

-

Warehouse Vehicle Detection with Indication

Warehouse Vehicle Detection with Indication

Vehicle detection at loading docks is complicated because sensing solutions are exposed to the elements and need to recognize a wide variety of surfaces. Rugged ultrasonic sensors work well to accurately detect the surfaces of delivery vehicles regardless of the material. Pairing with bright LED indication creates unmistakable operator guidance.

-

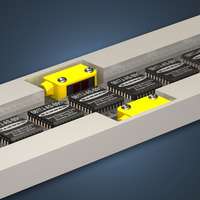

Counting Integrated Circuits

Counting Integrated Circuits

In order to detect these chips as they move down the conveyor, powerful sensors need to rapidly and accurately count them, but there are not many sensors that are tiny enough to fit into tight, confined spaces and still have reliable, speedy detection that keeps up with the integrated circuits as they pass by. With Banner’s ultra-miniature compact Q12 sensor, counting integrated circuits on the manufacturing line is simple.

-

Counting Memory Sticks

Counting Memory Sticks

As memory sticks used in digital devices pass on a conveyor, the WORLD-BEAM Q12 counts the sticks by detecting the slight difference in height between the stick and the conveyor belt.

-

Bond Wire Break Detection with a Fiber Optic Pair

Bond Wire Break Detection with a Fiber Optic Pair

A semiconductor company requested a sensor to detect breakage of very fine wire during assembly to eliminate unscheduled downtime.

-

Error Proofing Integrated Circuit Chips Loaded into Pocket Tape

Error Proofing Integrated Circuit Chips Loaded into Pocket Tape

• Confirm presence and orientation of IC chips • Sensor performs multiple functions at once • Cost savings and versatility