Miglioramento dell'efficacia complessiva dei macchinari mediante monitoraggio dei materiali in entrata e in uscita nelle/dalle linee di produzione

Applicazione: i sensori wireless ottimizzati per il conteggio dei pezzi sono utilizzati per monitorare l'efficienza e le prestazioni di produzione

Sfide: aggiunta di funzionalità di monitoraggio ad apparecchiature esistenti.

Raccolta di dati da più punti su una linea di produzione di grandi dimensioni.

Ricablaggio dei sensori per adeguarsi ai frequenti cambi di prodotto.

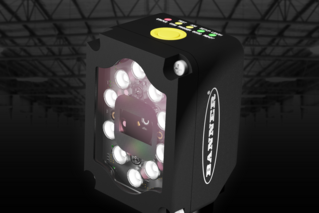

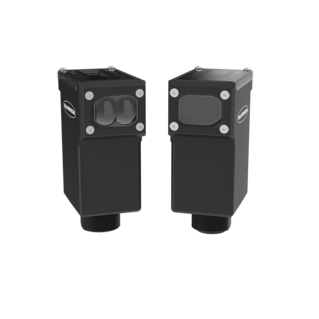

La soluzione: sensori wireless Sure Cross® Q45 e un modulo di controllo wireless Serie DXM

Vantaggi per il cliente

Incremento dei tempi produttivi: il sistema è configurato per avvisare il personale tramite messaggi di testo o e-mail se i parametri delle prestazioni non rientrano nei livelli definiti dall'utente; in questo modo è possibile adottare opportune contromisure e risolvere rapidamente qualsiasi problema

Monitoraggio remoto: non è richiesta la presenza del personale per raccogliere i dati. Possibilità di monitorare contemporaneamente più punti tramite la rete, a partire da una pratica posizione centralizzata.

Implementazioni versatili: la soluzione wireless plug-and-play è facile da installare su apparecchiature esistenti, semplifica la riconfigurazione della linea e può essere utilizzata in punti remoti difficilmente accessibili, dove una soluzione cablata sarebbe complicata se non impossibile da installare.

Antefatto

Monitorando i materiali in entrata e i prodotti in uscita, gli operatori e i responsabili possono disporre di dati critici su processi e macchinari che consentano di identificare e risolvere i problemi sulle linee di produzione in modo più rapido.

Sfide

L'acquisizione e l'accesso ai dati di produzione, in particolare con apparecchiature esistenti, possono risultare difficili. L'uso di sensori e di cavi di comunicazione può richiedere molto tempo e denaro, oltre a modifiche significative all'infrastruttura locale.

Soluzione

Montati in più punti strategici lungo la linea di produzione, i sensori wireless Sure Cross® Q45 contano e totalizzano i pezzi in entrata e in uscita nei/dai macchinari di produzione. Ogni Q45 comprende un sensore, un dispositivo radio wireless e batterie al litio a lunga durata, per rendere l'installazione facile e plug-and-play. I modelli Q45 a tasteggio diffuso e a riflessione sono preconfigurati per il conteggio e la totalizzazione dei pezzi, così da semplificare la configurazione e consentire una rapida implementazione. Il sensore è facilmente configurabile per contare e totalizzare fino a 960 pezzi al minuto, utilizzando i DIP switch integrati.

Le informazioni raccolte dal sensore wireless Q45 vengono trasmesse a un modulo di controllo wireless Serie DXM a intervalli regolari, tramite una rete wireless Sure Cross protetta; il modulo di controllo utilizza i valori conteggiati per determinare se il macchinario funziona normalmente o lentamente, se è fermo, inceppato o privo di pezzi. Quando i parametri prestazionali delle macchine non rientrano nei livelli definiti dall'utente, il DXM invia un avviso al personale tramite e-mail o SMS, assicurando così una reazione rapida e la tempestiva risoluzione di problemi sulla linea. Gli utenti possono tenere traccia dei pezzi al minuto, monitorare lo stato delle macchine e raccogliere dati per i calcoli sull'efficienza complessiva dei macchinari (OEE).

Caratteristiche e vantaggi

| Feature | Benefit |

|---|---|

| Feature Overall Equipment Effectiveness (OEE) Calculations | Benefit Calculates OEE actual vs. user defined ideal state answering: “How close is system to ideal state”. Instantaneous and averaged OEE parameters calculated including Availability (A), Performance (P), and Quality (Q). OEE = A × P × Q |

| Feature Part Counting | Benefit Use up to 8 pairs of battery-powered Wireless Q45 Nodes for part counting up to 960 parts/min |

| Feature Track Parts per Minute | Benefit Calculates parts/min rates for each counting pair of sensor nodes |

| Feature Monitor Machine State | Benefit By counting in/out - Determines machine states: Running, Slowed, Stopped, Jammed, or Starved based on part rates and user configurable settings. Track times and counts of error states. |

| Feature Extended Error Alerts | Benefit User configurable parameters to trigger alerts when error states are active for extended periods |

| Feature Alerts and Notifications | Benefit Generate SMS text and/or email alerts based on specific events |

| Feature Wireless Sensors | Benefit No additional control or power wires to install |

| Feature Scalability | Benefit Ability to easily add additional wireless nodes to monitor other operations |

| Feature IIoT / Cloud Monitoring | Benefit Push data to Cloud webserver or PLC (via LAN or cellular connection) for remote viewing, alerting, and logging |