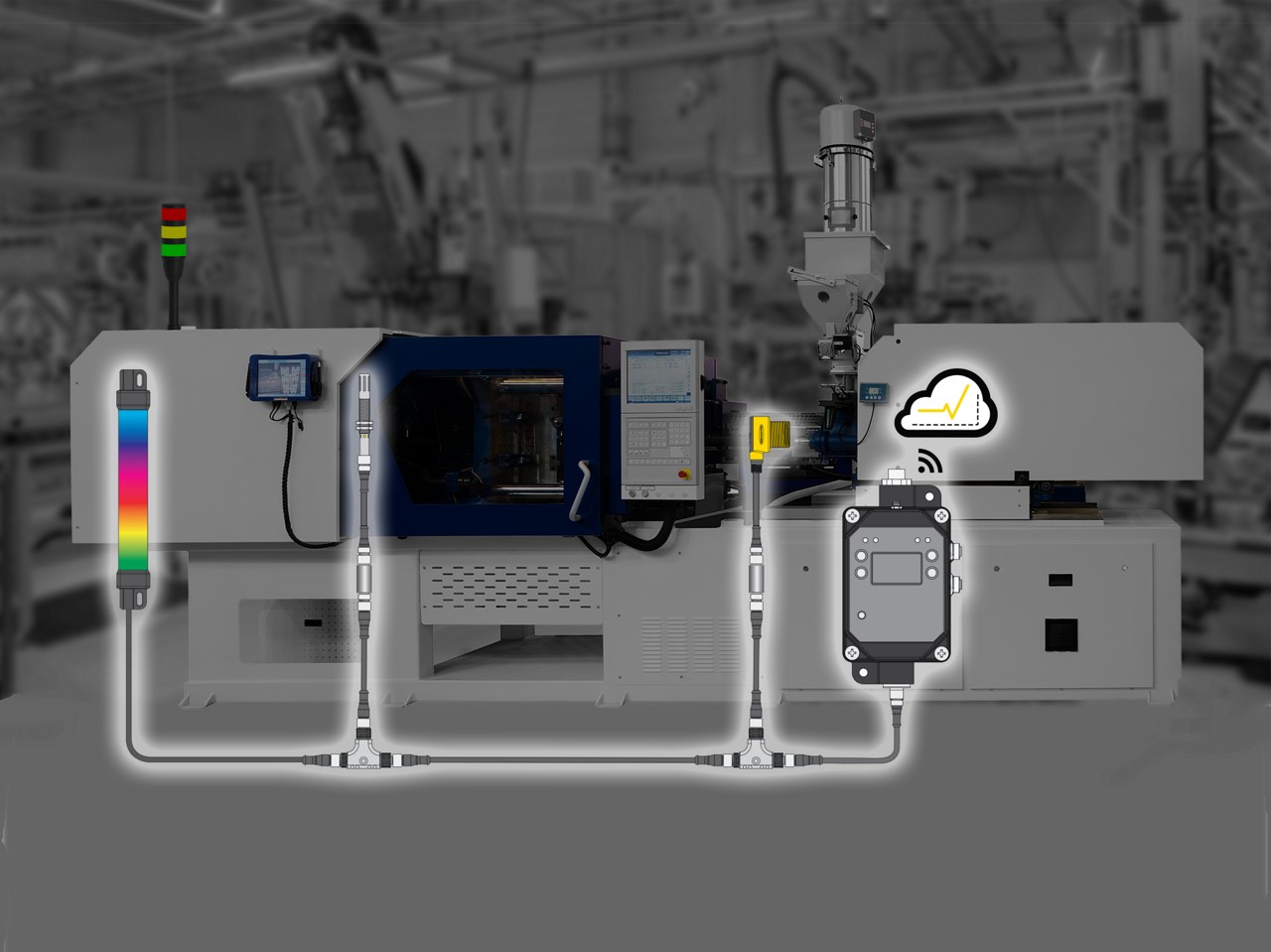

Aumenta la produttività di una macchina per lo stampaggio a iniezione

Snap Signal aggiunge funzioni intelligenti alle vecchie macchine per lo stampaggio a iniezione, aggiornandole allo standard Industry 4.0.

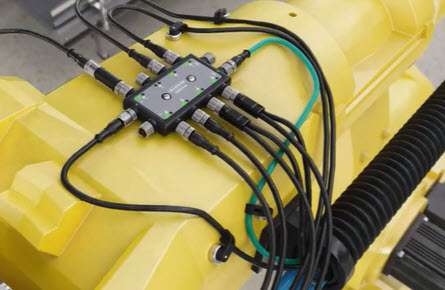

DXM Series industrial wireless controllers are designed to facilitate Ethernet connectivity and Industrial Internet of Things (IIoT) applications. Available with an internal DX80 Gateway or a MultiHop Data Radio, these powerful Modbus communications devices connect local wireless networks with the internet and/or host systems.

Modulo di controllo industriale: Serie DXM

Snap Signal aggiunge funzioni intelligenti alle vecchie macchine per lo stampaggio a iniezione, aggiornandole allo standard Industry 4.0.

![Manutenzione predittiva per componenti rotanti su nastro [Testimonianza di successo]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_111970609.jpeg/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Il monitoraggio wireless delle parti rotanti di nastri adibiti al trasporto di carbone attraverso una grande porta consente agli operatori di utilizzare la manutenzione predittiva per prevenire guasti e risparmiare denaro, riducendo così i fermi impianto.

![Manutenzione preventiva di motori e riduttori di gru di grandi dimensioni [Testimonianza di successo]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/bigstock-In-A-Port-49071524.jpg/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

I prodotti wireless consentono l'uso della manutenzione predittiva nel settore marittimo-portuale. I motori e i riduttori delle gru sono soggetti ad alti livelli di vibrazioni e temperature estreme che possono causarne il degrado. La manutenzione predittiva consente ai dipendenti di intervenire e risolvere i problemi prima che si verifichi un guasto, con conseguenti fermi imprevisti e perdita di lucro.

![Vibration Monitoring a Main Air Handler [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/predictive-maint/qm30vt-motor-vibration-detection.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Learn how the installation of Banner wireless vibration sensors and data from the DXM wireless gateway prevented unplanned downtime in this application.

Identificazione dei problemi della macchina prima che provochino gravi danni o fermi impianto non pianificati, notifica al personale di cambiamenti nelle condizioni con messaggi di testo o e-mail e segnalazione locale immediata dello stato della macchina.

• Indicazione sullo stato della macchina a colpo d'occhio </br> • Invio delle informazioni acquisite a un'ampia gamma di dispositivi </br> • Notifiche SMS oppure e-mail per segnalare al personale ed ai supervisori eventuali condizioni critiche </br>

• Expand available data beyond local indication</br> • Gather information necessary to react quickly</br> • Drive efficiency improvements based on data previously unavailable</br>

The K50U wireless ultrasonic sensor was designed specifically as a non-contact level monitoring solution. Monitoring the levels of epoxy in drums during refill alerts staff of potential overflows before they become a problem.

Increase production efficiency by developing a wireless call-for-parts, service, and Andon system that allows for up to 35 work stations to call out to 12 forklifts/Hi-Los using the EZ-Light K70 Touch to wireless Direct Select operator interface.

Monitorando i materiali in entrata e i prodotti in uscita, gli operatori e i responsabili possono disporre di dati critici su processi e macchinari che consentano di identificare e risolvere i problemi sulle linee di produzione in modo più rapido.

Predictive maintenance enables users to more accurately anticipate when machine maintenance will be needed based on real-time data from the machines themselves.

Remote monitoring enables increased visibility into the performance and efficiency of machines, processes, and people.

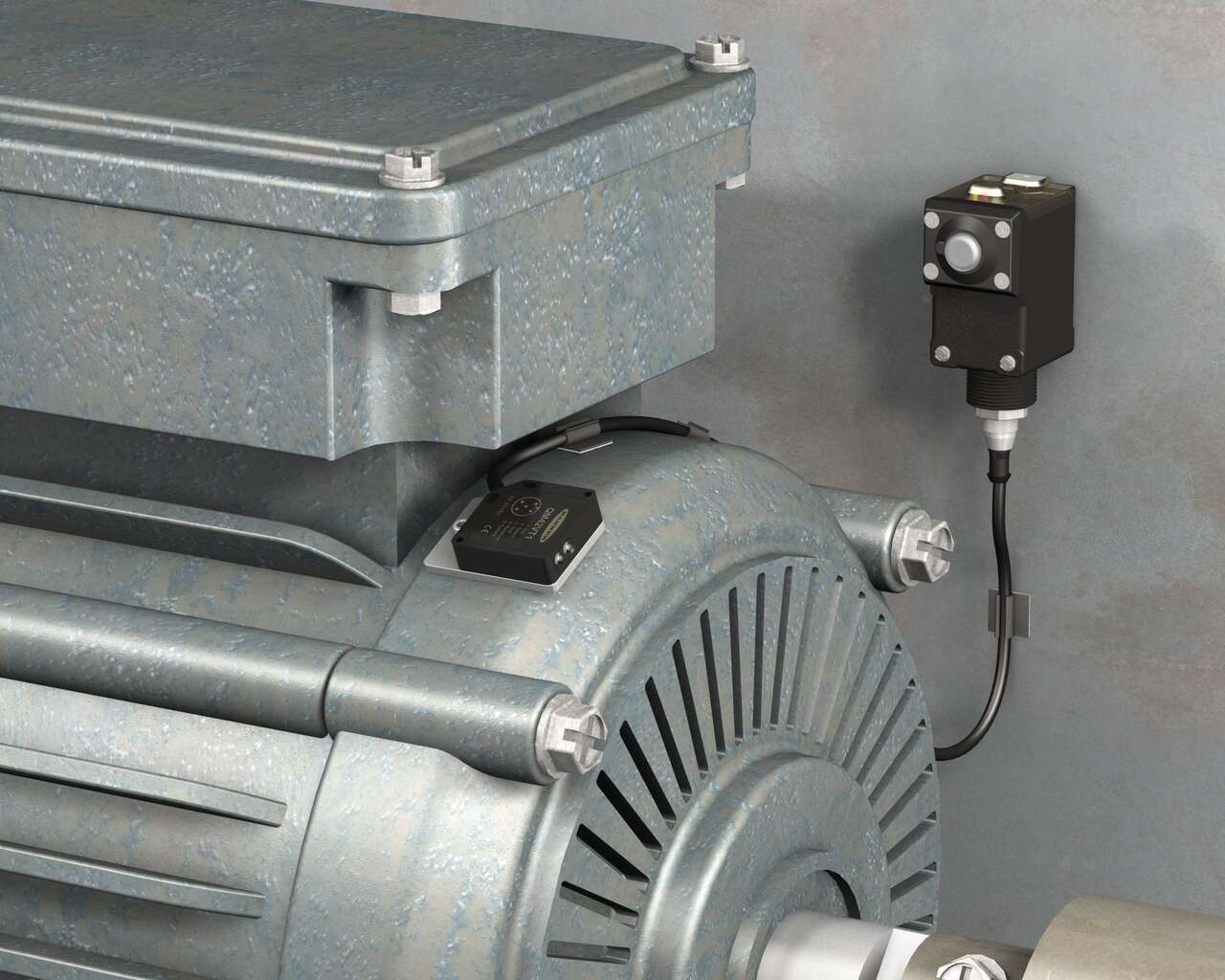

Banner’s wireless vibration and temperature sensor measures RMS velocity, in inches per second or millimeters per second, and temperature. Mounting it as close as possible to the bearings enables you to monitor the machine’s health by detecting increases in vibration and temperature. It is easy to mount using the standard bracket, the magnetic bracket or two sided thermal transfer mounting tape.

• Rimozione rapida dei pallet completati dalle stazioni di assemblaggio </br> • Comunicazione diretta tra stazioni di assemblaggio e carrelli autoguidati </br> • Maggiore efficienza di processo grazie ai dati sulle tempistiche </br>

In a recent material handling application, facility managers needed to find a solution that would alert them to the status of trailer capacity at loading dock doors in real-time.

Learn how In the Ditch™, an Idaho-based manufacturer of award-winning products for the towing industry, was able to make substantial improvements to the efficiency and accuracy of their picking processes by implementing a complete pick-to-light system from Banner Engineering.

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

Additional Technical Notes available in the Wireless Reference Library.

Learn how to connect the Banner DXM Gateway series with the Ignition SCADA software.

Monitor machine health utilizing predictive maintenance by continuously monitoring for vibration and temperature changes.

![Wireless Call for Parts, Services, and Pick-Up Solution [Video]](/content/dam/banner-engineering/3d-renders/product-group/multi_division/call-for-parts/Wireless-Call-for-Parts-Group-off.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Learn how to improve communication and maintain a steady workflow with Banner Engineering's wireless call for parts solution.

![Calculate OEE with a Wireless Solution [Video]](/content/dam/banner-engineering/projects/video-thumbnails/OEE_to_improve_productivity-new.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Calculating Overall Equipment Effectiveness (OEE) can help you improve efficiency and productivity. With a wireless system, you can track uptime, validate throughput, monitor quality, and optimize your operation.

IIoT solutions from Banner Engineering provide companies with greater visibility into their operations by enabling access to critical performance and production data, making it easy to solve problems, identify trends, and make better, data driven decisions.

Have a question about this product series? Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.