Factory Communication and Process Optimization

Communicate Better, Improve Worker Productivity

Industrial Internet of Things (IIoT) technologies are not just useful for optimizing machines. In fact, wireless technologies enable seamless interaction among human workers as well, and can have a significant impact on the efficiency of manual or semi-automated production and assembly lines.

Keep reading to learn how IIoT technologies enable better communication throughout the factory and streamline processes for machines and people alike.

Combining wireless communication with bright indication enables more seamless interaction between machines, workers, mobile equipment, and their managers throughout the factory.

Workers can quickly and easily interpret signals from LED indicators with clear, bright local displays, especially when each status is represented by a unique color or animation.

Furthermore, LED indicators with wireless communication make it easy to quickly send and receive these signals from anywhere in the factory--and respond in a timely manner.

Keep Stations Stocked for Continuous Workflow

Assembly workers need the correct supplies in order to build products and maintain a smooth workflow. Restocking assembly stations on-time, before components run out without overstocking and creating congestion at a station can be a challenge. Real-time communication between assemblers and the forklift operators who stock their stations enables a more efficient delivery of components as well as the timely removal of completed products.

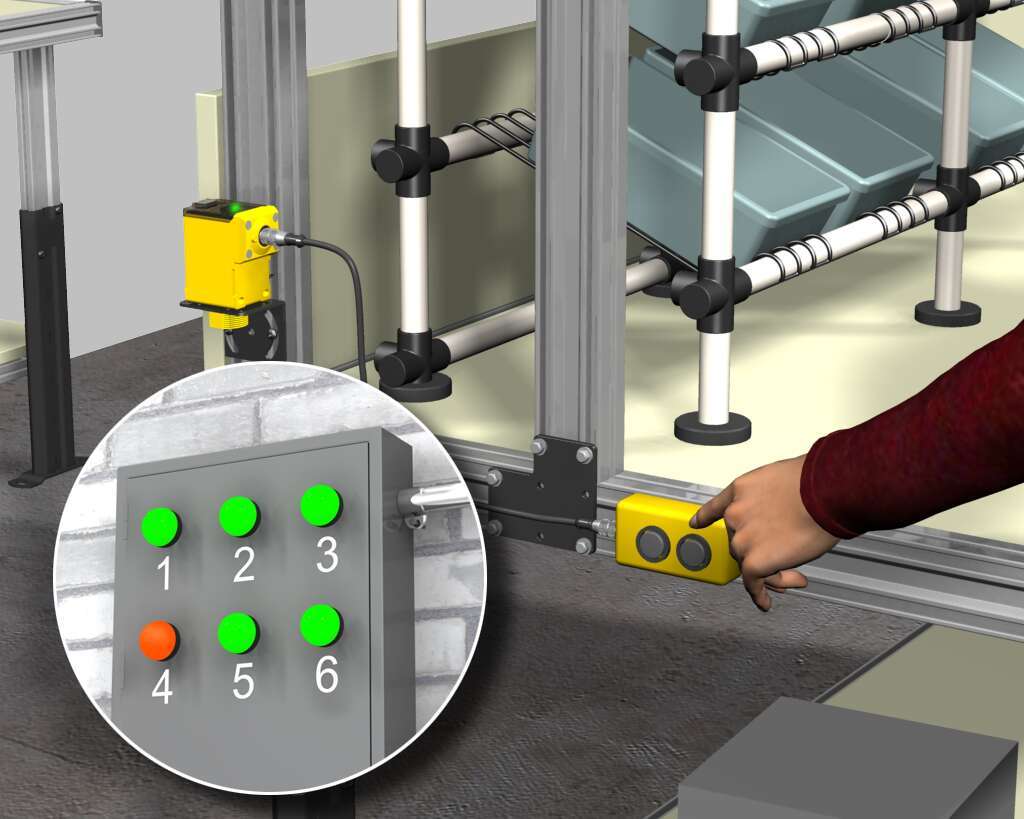

When an assembly station needs to be restocked, a worker can simply touch a button at their station. The button sends a signal to a pendant that the forklift operator carries. A red LED light on the pendant that corresponds with the assembly station will begin to flash, notifying the forklift operator where parts are needed. The driver can quickly acknowldege the request by pushing a button on the pendant, letting the operator know more material is on the way.

Use Data to Identify Process Improvements

A wireless call-for-parts, service, or pallet pickup system increases efficiency by allowing up to 18 work stations to call out to six forklifts or Hi-Los. A wireless solution enables quicker responses from forklift drivers and/or supervisors to indicate a request has been accepted. When creating a call system using wireless indicators, work stations can maintain a steady workflow and resolve critical issues quickly.

A wireless solution can also track total time to fulfill requests, number of requests, and time to acknowledge requests. This allows managers to analyze average delivery and acknowledgement times for each station and make process improvements as needed.

Reduce Time Spent Checking In Unnecessarily

Instead of requiring machine operators to walk over to the manager area for assistance with a technical issue, a wireless system utilizing connected pushbuttons or switches and tower lights can be used to alert managers when assistance is needed on the line.

For example, a notification system might be set up so that an operator pushes a button or flips a switch to alert the manager or technician that he or she is needed on the production line. Wireless pushbuttons equipped with LED status lights can also facilitate 2-way communication by configuring the LED to change color when the manager or technician indicates that he or she is on their way.

Using a wireless notification system reduces the need for technicians and managers to constantly check each production line and for workers to leave their workstations when they need assistance. By streamlining communications, managers, technicians, and line workers are able to use their time more productively.

Wireless Pushbuttons and Switches

Gli interruttori e i pulsanti Q45 sono progettati per l'uso con contatti puliti, NAMUR, e ingressi di interruttori senza contatto digitali e sono adatti a molte applicazioni di automazione industriale, monitoraggio remoto e IIoT.

- I modelli di dispositivi remoti sono progettati per interfacciarsi con ingressi a contatti puliti isolati o con sensori di prossimità induttivi NAMUR

- I modelli di pulsanti e indicatori dispongono di ingressi a pulsante controllati in modo indipendente e di un indicatore a LED multicolore

- I modelli di interruttori senza contatto digitali utilizzano un interruttore reed e un magnete per rilevare la posizione di dispositivi meccanici quali porte, leve, valvole e altri attuatori

Wireless Button and Light Pendant

Il telecomando wireless Sure Cross® Q120 a pulsanti e con indicatori luminosi è un nodo wireless autonomo che consente la comunicazione bidirezionale tra l'operatore e un massimo di sei dispositivi remoti e/o mobili.

- Con sei ingressi a pulsanti controllati in modo indipendente, gli operatori possono inviare conferme e aggiornamenti sullo stato e anche di avviare dei processi e azionare dei dispositivi in modalità wireless.

- Sei indicatori LED rossi e verdi forniscono un'indicazione locale dello stato di apparecchi e dispositivi remoti o mobili.

- Configurabile tramite DIP switch:

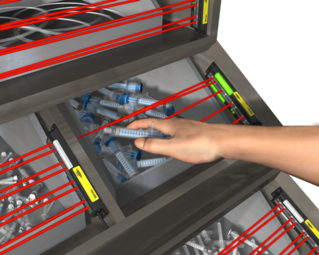

Wireless LED Touch Button

Il pulsante a sfioramento K70 wireless da 70 mm è un dispositivo a stato solido grande e facile da attivare che integra un indicatore ad alta visibilità. I pulsanti a sfioramento di questa serie sono l'ideale per processi di prelievo guidato "pick-to-light" e di richiesta di componenti,oltre cheper applicazioni industriali in generale.

- Eccellente immunità alle attivazioni indesiderate causate da spruzzi d'acqua, detergenti, oli o altre sostanze estranee

- Ergonomico, progettato per eliminare ogni sforzo fisico della mano, del polso e del braccio normalmente provocato da operazioni ripetute. Il funzionamento l'applicazione di forza fisica

- Azionamento a mani nude o con i guanti da lavoro

- Disponibile in nove colori e in modelli a uno, due e tre colori

- Tensione di alimentazione 12-30 Vcc