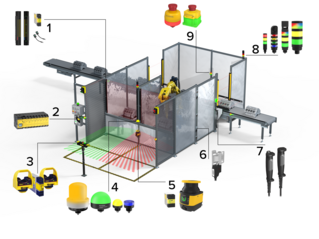

Machine Guarding at the Point of Operation

Guard Hazards Where Work is Performed

The point of operation on a machine is where the work is performed. Guarding the point of operation is critical to protecting personnel from accident or injury as well as preventing equipment damage.

In many point of operation applications, operators must work in very close proximity to the hazard. Hard guards can be impractical in these applications, as they can reduce ergonomics and productivity of operators. Optical sensing technologies, like safety light curtains, protect the point of operation while allowing operators to interact with the machine more seamlessly.

Safety light curtains typically consist of an emitter and receiver—where the emitter sends beams of light to the receiver—creating a sensing screen that guards machine hazards The light curtain can detect when an individual or object interrupts any beam in the screen and can trigger a halt to the hazardous motion.

Safety light curtains can be rated Type 2 or Type 4 depending on the level of risk they protect against, and they come in a variety of resolutions (distance between beams) to detect an arm, hand, or finger. The specific resolution required will depend on your application, how far away the light curtain is placed from the hazard, and how quickly the hazardous motion can be halted based on a minimum safety distance calculation.

Please note: The information on this page is meant for educational purposes only and is accurate as of the time of publication. Always consult a safety expert about your specific application before implementing any machine safety measures.

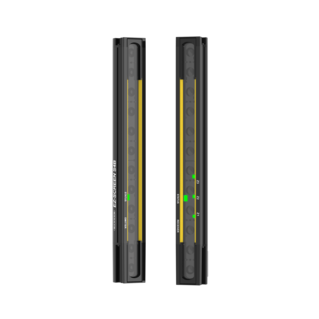

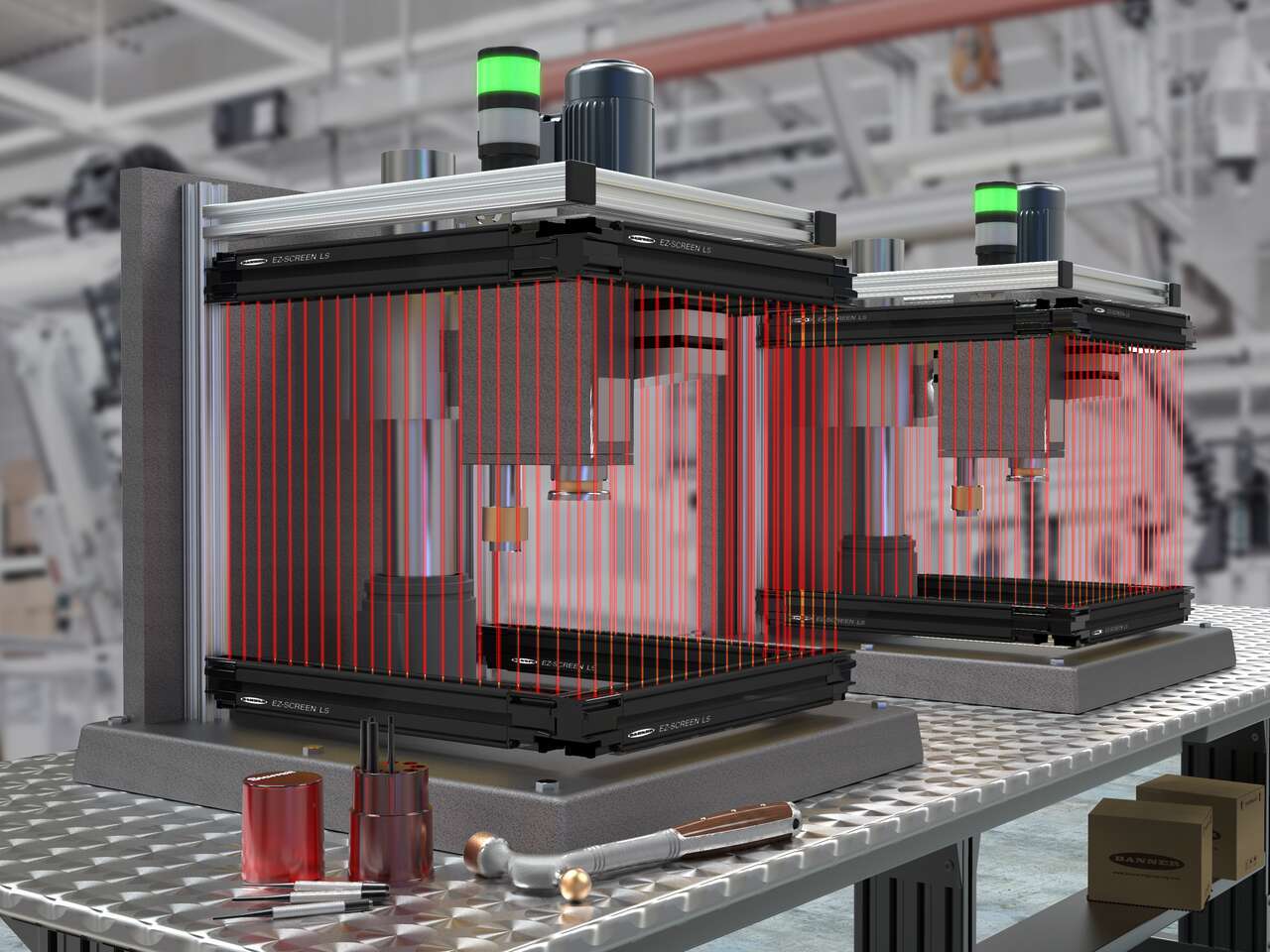

End-To-End Sensing Ensures No Gaps in Protection

When using a safety light curtain for point of operation applications, it is critical to ensure that there are no gaps where a finger or hand could go around the protective beam of light undetected.

Many safety light curtains now feature end-to-end sensing, which means that the protective beams of light extend across the entire length of the light curtain. In the image to the left, you can see that the beams go all the way to the end of the light curtain, which means there are no gaps even when light curtains are cascaded together in various configurations.

If there are blind zones or other gaps, these must be taken into consideration when designing the safety system. A risk assessment is an important first step in any safety project to ensure that considerations like these are accounted for and addressed before implementation.

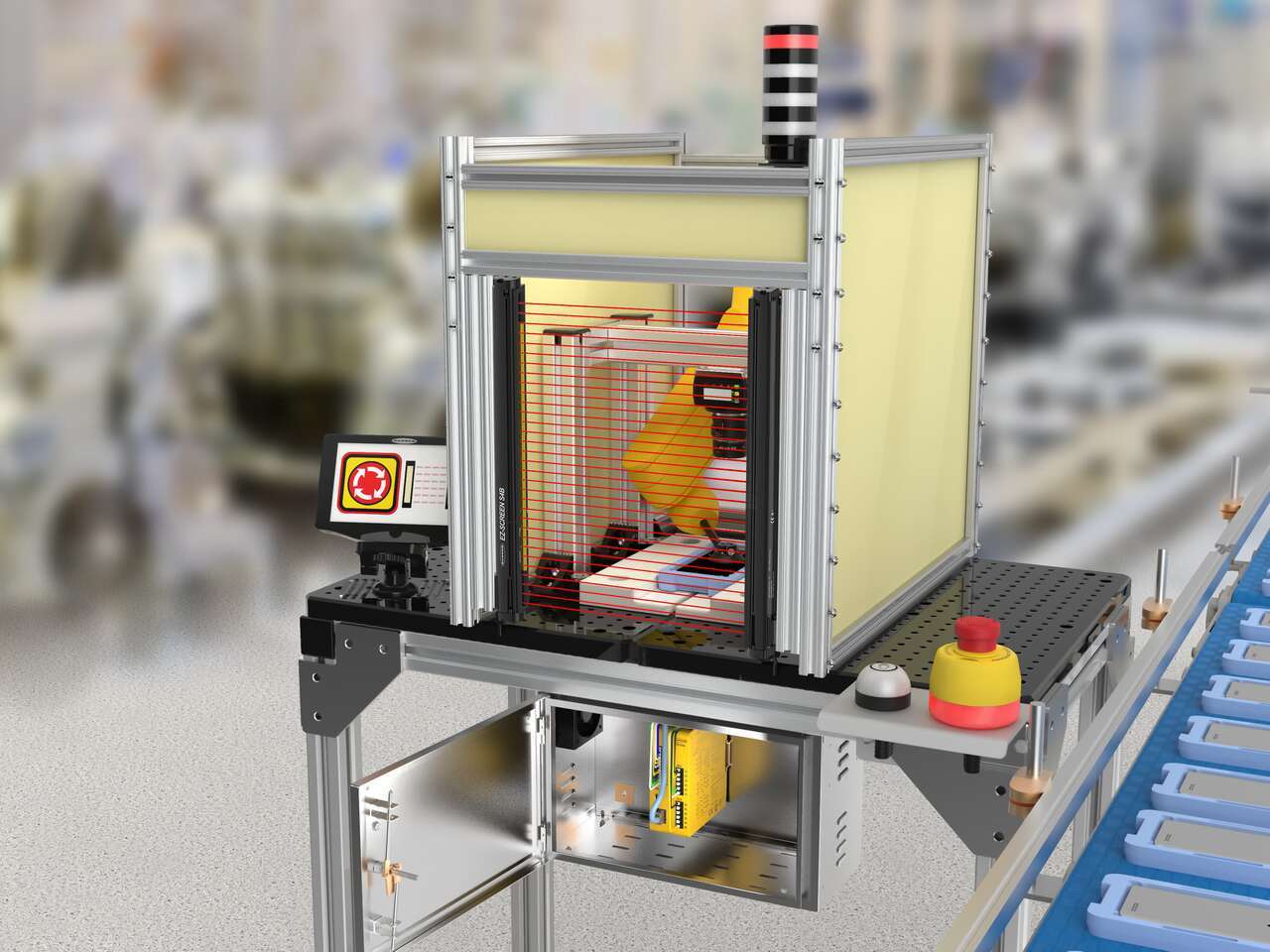

Ergonomic Safety for Even the Tightest Spaces

Optical safety devices often save space and improve operator ergonomics compared to doors and other hard guards. Safety light curtains facilitate a more seamless operator interaction with the machine, which can help improve productivity.

Near the point of operation, space is often limited. While safety light curtains are available in a wide range of protective heights, they can also be extremely compact and low profile for even the tightest spaces.

Rugged Design Ensures Safety in All Environments

Industrial environments can be punishing for safety devices. When choosing an industrial safety device, consider the surrounding environment to ensure that the ruggedness of the device meets your application requirements. For example, features like heavy-duty aluminum housing and a recessed lens protect safety light curtains from damage due to impact.

In addition, in food processing applications, light curtains mounted close to the process must endure frequent high pressure, high temperature washdown to adhere to food safety standards. Many light curtains can be equipped with IP69K-rated protective enclosures to ensure reliable operation in these harsh conditions.

Easy-to-Use, Full-Featured Safety Light Curtain

Le barriere ottiche LS sono dispositivi di sicurezza intuitivi e facili da usare utilizzati per la protezione di macchinari. Realizzate per resistere alle condizioni tipiche degli ambienti di produzione e di confezionamento.

- Modelli completi di tutte le funzioni, con opzioni adatte a una vasta gamma di applicazioni

- Custodia heavy-duty in alluminio e finestra a incasso per evitar danni in condizioni ambientali difficili

- Rilevamento end-to-end

- Allineamento e indicatori di diagnostica a elevata visibilità

- Risoluzione 14, 23 e 40 mm (funzionalità di rilevamento)

- Disponibile con 23 zone di rilevamento configurabili da 280 a 1820 mm, in incrementi di 70 mm

- Grado di protezione IP65/IP67, disponibile anche in versione IP69K

Full-Featured, Low Profile Safety Light Curtain

Il profilo compatto e a ingombro ridotto dell'LP ne fanno la soluzione ideale per piccole macchine, anche se la sua robustezza ne consente l'uso in applicazioni per il controllo di presse meccaniche di grandi dimensioni.

- Rilevamento continuo senza zone cieche

- Zona di rilevamento con risoluzione di 14 mm o 25 mm e altezza da 270 mm a 1810 mm (da 10,6" a 71,2")

- Profilo compatto e svariate opzioni di montaggio per una vasta gamma di applicazioni di protezione dei macchinari

- Soddisfa ampiamente i requisiti OSHA/ANSI per l'Affidabilità del controllo, dispone della certificazione cULus NIPF e CE, Tipo 4, Categoria 4PLe e SIL

Compact Light Curtain for Simple Applications

Le barriere ottiche di sicurezza SLC4 sono il nostro modello più compatto e più corto. Sono progettate per la protezione di punti di accesso e operativi di piccole macchine di produzione e macchinari simili.

- Altezza zona di rilevamento da 160 mm a 320 mm

- Portata di rilevamento da 0,1 m a 2 m (da 4 " a 6,5 piedi)

- Disponibili con risoluzioni di 14 mm (rilevamento dita) o 24 mm (rilevamento mani)

- Robusto corpo interno in alluminio con custodia in policarbonato con grado di protezione IP65

- Funzionalità di base con avvio/riavvio automatico (uscita "trip")

- Tecnologia di rilevamento end-to-end (senza zona cieca)

![Washdown Cover for Emergency Stop Buttons [Video]](/content/dam/banner-engineering/projects/video-thumbnails/E-Stop_Cover_Video_Thumbnail-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)