AGV Status Indication

Challenge

Design engineers at an AGV (Automated Guided Vehicle) manufacturer were looking for ways to add lights to their vehicles that would help communicate the status of the AGV with people who would be working around them. For example, adding turn signals on an AGV to show those in the area its direction of travel. The lights would need to be installed around the curved corners found on the machine, ruling out typical industrial lighting products.

Solution

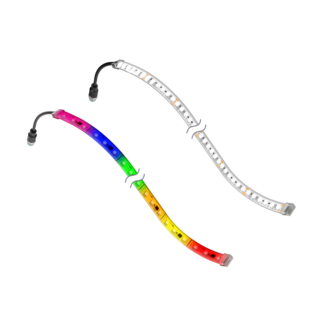

The WLF12 Pro was chosen because of its flexible and durable housing, peel-and-stick installation, multiple color options, and animation capabilities. Because the WLF12 comes in five lengths and can be further customized by cutting to lengths that better fit the application, the manufacturer was able to find a model that was an exact fit for their needs. The high strength adhesive backing allowed the lights to be mounted quickly. The electrical installation was also simplified by using industry standard M12 connectors and avoiding the need for any special soldering or connectors to be added to the lights. Lastly, engineers configured the WLF12 Pro to display the colors and animations needed to communicate various AGV states to people nearby.