Workstation and Area Lighting

Bright, Even Lighting Where You Need It Most

Operators need bright illumination in workstations to accurately and efficiently complete tasks. Workstation and area lighting solutions from Banner Engineering provide bright LED illumination and feature intensity control options that allow operators to adjust light level and switch the light off when they are done.

The bright, even light output with no hot spots increases worker productivity and ergonomics and provides illumination exactly where needed. In addition, our high performance LED lights provide years of maintenance-free operation, with no bulb or ballast changes required throughout the lifespan of the device

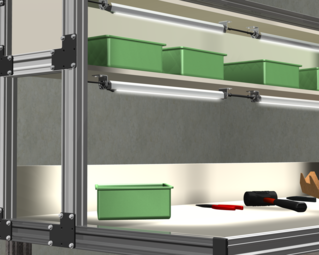

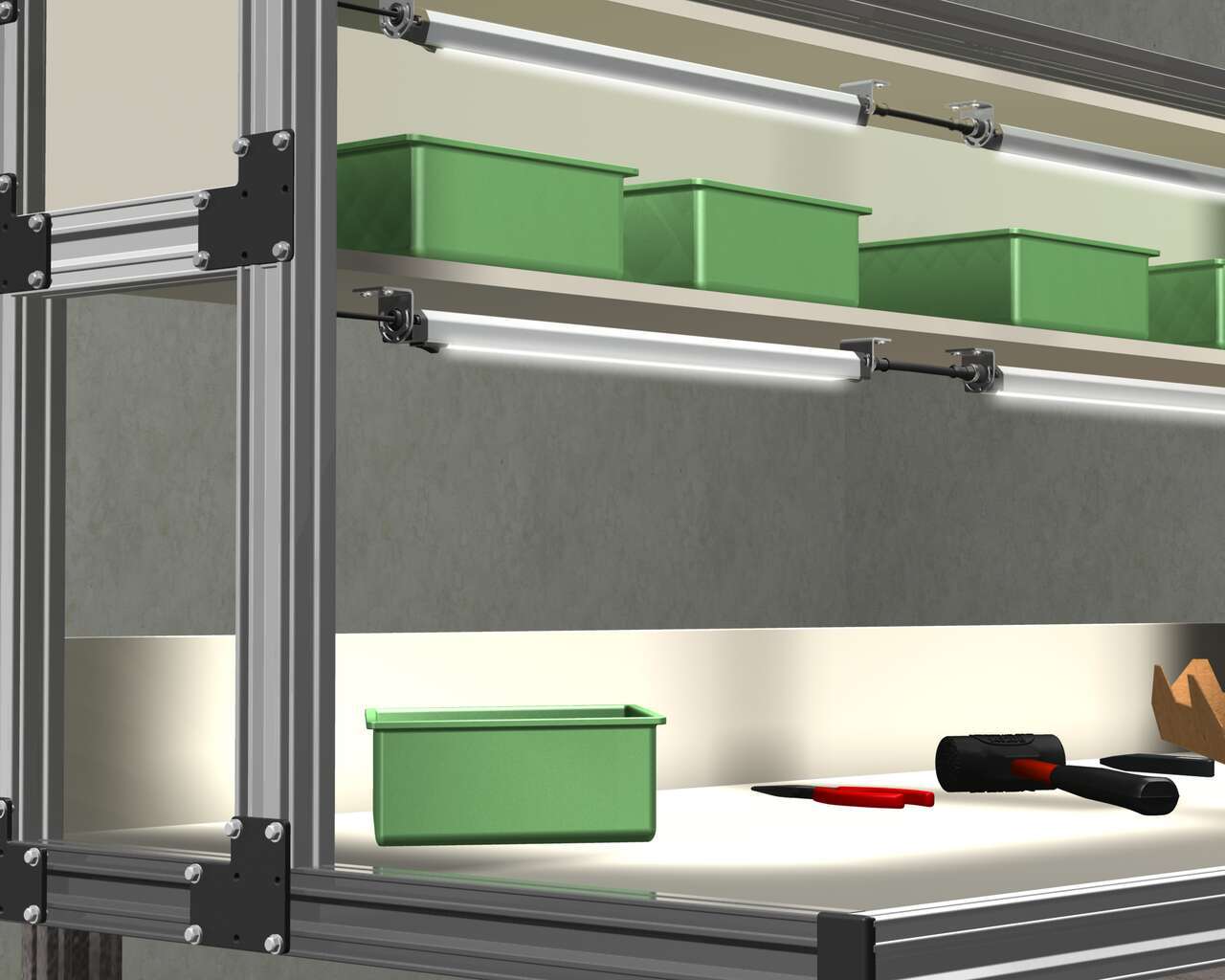

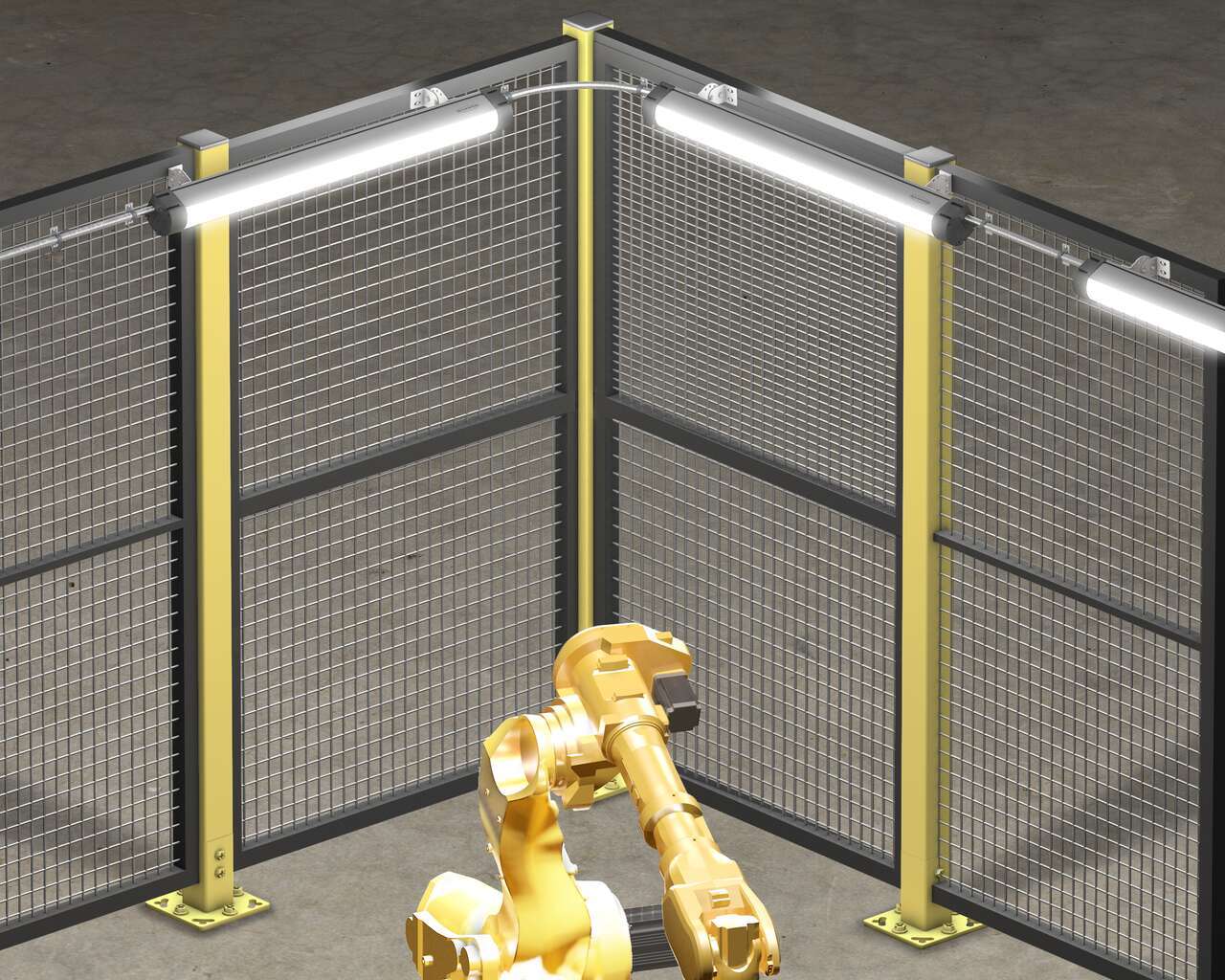

Workstations and other work areas often have structures around them--such as shelving or hard guarding--that obstruct overhead lights and result in a dim workspace.

Even without obstructions, overhead lighting is often insufficient to illuminate detailed tasks and processes. Lack of proper lighting can increase the risk of operator error, as well as lead to eye strain and operator fatigue, which reduce quality and productivity.

Installing bright LED lights at a workspace can help achieve the right amount of concentrated light to complete tasks quickly and accurately while improving worker ergonomics and comfort.

Keep reading to learn more about how LED lights can solve a variety of illumination challenges throughout your facility, or contact us to discuss your specific illumination needs.

Adjust Illumination to the Task and Worker

Operators need bright, even illumination to accurately and efficiently complete tasks, such as inspections and assembly. Each task and operator require different levels of light.

The table shows recommended lux levels for different applications and ages of workers. Use a lux meter to determine lux levels to help ensure your illumination levels are sufficient for the space, task, and people.

| Application | Lux Ages 25-65 | Lux Ages 65+ |

|---|---|---|

| Warehouse | 100 | 200 |

| Work area | 150 | 300 |

| General assembly | 1,000 | 2,000 |

| Detailed assembly | 2,000 | 4,000 |

| Fine inspection | 5,000 | 10,000 |

Illuminate Large Areas with Fewer Devices

- Getting consistent lighting across a large area can be challenging with traditional fluorescent lighting.

- To light up a large warehouse or similar area, a bright LED lighting can provide an efficient, low-maintenance solution.

- The heavy-duty, energy-saving WLB92 from Banner Engineering provides an exceptionally bright lighting solution that provides consistent lighting across a warehouse.

- Since the WLB92 is so bright and gives a uniform output, fewer lights are needed in total, helping reduce the overall cost of lights and installation time.

Safely Illuminate Photosensitive Processes

- Some applications are photosensitive, which means that white light can damage materials in the process. Colored light can be used to illuminate these applications without damage.

- For example, photolithography involves transferring a pattern from a mask to a substrate using a photosensitive polymer known as a photoresist. An undeveloped photoresist is sensitive to white light, especially blue wavelengths (400 nm) emitted from fluorescent bulbs and specific LEDs.

- When the color is achieved with phosphor-converted LEDs, the yellow light can also be problematic. Phosphor-converted LEDs produce the color by coating blue LEDs with phosphor coating and therefore still emit a percentage of blue wavelengths.

- However, the WLS15 amber models are safe for photosensitive applications because they are composed of non-phosphor converted LEDs (AlInGaP). These LEDs have a spectral output >560 nm and a blue wavelength content of <0.35%.

Adjustable LED Workstation Light

バナー社製WLB32は明るいLED照明で、均一な照度分布によりグレアを排除します。

- エネルギー効率が高く、全体的にコストを節約できます。

- 高/低/オフスイッチにより照度のカスタマイズが可能

- 配線を最少に抑えながら照明を持続できるカスケード式モデルも選択可

- 金属ハウジング、飛散防止ガラス。

- スナップクリップ、マグネットブラケットまたはL字ブラケットを用いて簡単に取り付け

- ACモデルとDCモデルをご用意

- 長さは285 mm、570 mm、850 mm、または1130 mm

- モーション検出モデルは、物理的なスイッチが使用できない場所やスイッチの配置が実用的でない場合に最適です。

- 保護シールド窓付きのモデルはドーム型窓への直接的な見通し線を遮る、目にやさしい仕様

Low Profile, Low Power LED Strip Light

ワークスペースおよび機械の広範な用途で視界の改善に役立つ、スマートなデザインの薄型ストリップライト。

- 狭いスペースにも簡単に設置できる薄型設計

- 1つのモデルでDC12Vおよび24Vに対応

- 濡れた環境や汚れた環境での使用に適した、IP67等級に対応した完全密閉構造

- 軽量でありながら衝撃や振動に耐える頑丈な構造とポリカーボネート製シェル

- 省エネで交換コストが最小限に抑えられるLED照明テクノロジー

- 用意に設置するためのブラケットおよびコネクタ

- 他のライトの半分の電力を消費する省エネ装置でエネルギーを大幅に節約

- 線間電圧の変動を安定化

- 照明と表示がひとつの堅牢な照明器具にまとめられた、EZ-STATUS® 付きの2色モデル

WLB92 Series

Ultra-Bright LED Strip Light

WLB92は非常に明るいLED照明で、均一な照度分布による明るいタスク照明で生産性を向上します。

- 明るく、高品質、均一な照度分布で作業員の生産性とエルゴノミクスを改善します。

- 頑丈な金属ハウジング、飛散防止照明カバーを備えた耐久性が高い照明

- 寿命が長くエネルギー効率に優れたLEDを使用しているため、メンテナンスにかかる時間やコストが不要

- ACモデルとDCモデルから選択できるため、必要なところに自在に配置

- 各種取り付けオプション (表面、スイベル、スナップ、吊りブラケット) を使用し、簡単に設置

- 白、温白色、青、赤、黄、緑を選択可

![LEDライトバー、蛍光照明より高い輝度で、機械の構築時間と費用を節約 [成功事例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/WLB32%20Muti-Station%20Test%20Workstation%20Illumination%20(High_Res_PSD).psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)