Track and Trace for Product Recall

Mitigate Damages with Accurate, Timely Recalls

An important goal for any manufacturer is to avoid product recall. Recalls are costly, in terms of both actual costs of repair, replacement, or buy-backs as well as the cost of a tarnished brand reputation.

Implementing quality control solutions can help reduce the risk of product defects and safety hazards; however, even the most effective quality control does not eliminate all risk.

Recalls happen, and when they do, it is critical that manufacturers are prepared to respond quickly by identifying affected products and issuing a timely recall to mitigate damages.

When recalls occur, a manufacturer's response can make or break its reputation, and by extension, impact customer loyalty and future profits.

Manufacturers must act quickly and recall all affected products that have already been purchased. In some cases, manufacturers must be able to quickly pull affected inventory from their own shelves, distribution centers, and retail establishments. In other instances, like in many automotive recalls, consumers may need their purchases repaired in a timely manner. Furthermore, to prevent unnecessary costs, manufacturers must avoid inadvertently recalling unaffected products.

Track and trace solutions help manufacturers execute recalls quickly and accurately, so that affected products can be repaired or removed from the market, and the issue can be resolved quickly.

These solutions depend on reliable identification of individual products throughout the supply chain—most commonly by scanning barcodes at every stage from production to purchase. Track and trace solutions are only as reliable as the devices that scan the codes, so selecting the appropriate identification technology is critical.

Track and Trace for Food Safety

- In food packaging, barcodes are embedded with information specific to each product and production run in order to identify products throughout the supply chain.

- As part of a track and trace program, a packing house verifies product barcodes at multiple points during packaging, creating a record that will allow the company to quickly identify and isolate any product with quality issues in the event of a recall.

- Imager-based barcode readers, like the ABR 3000 from Banner, are capable of decoding the widest range of 1D and 2D barcodes. Deployed along the packaging line, the ABR 3000 verifies that the barcode printed on each package is present, readable, and correct for each production run.

- The information contained in the barcodes is sent via an Ethernet connection to the company’s production management system which records the data for future referrence.

Track and Trace for Automotive Components

- Many automotive suppliers are incorporating Ultra Violet (UV) barcodes for component traceability and quality control.

- The technology uses UV-based ink that is only visible to the human eye when illuminated with a UV light source. Suppliers can store key informationin a small code printed directly on the component, without affecting design or aesthetics.

- In the event of a recall, codes can be scanned to verify that components were installed and tested in compliance with standards.

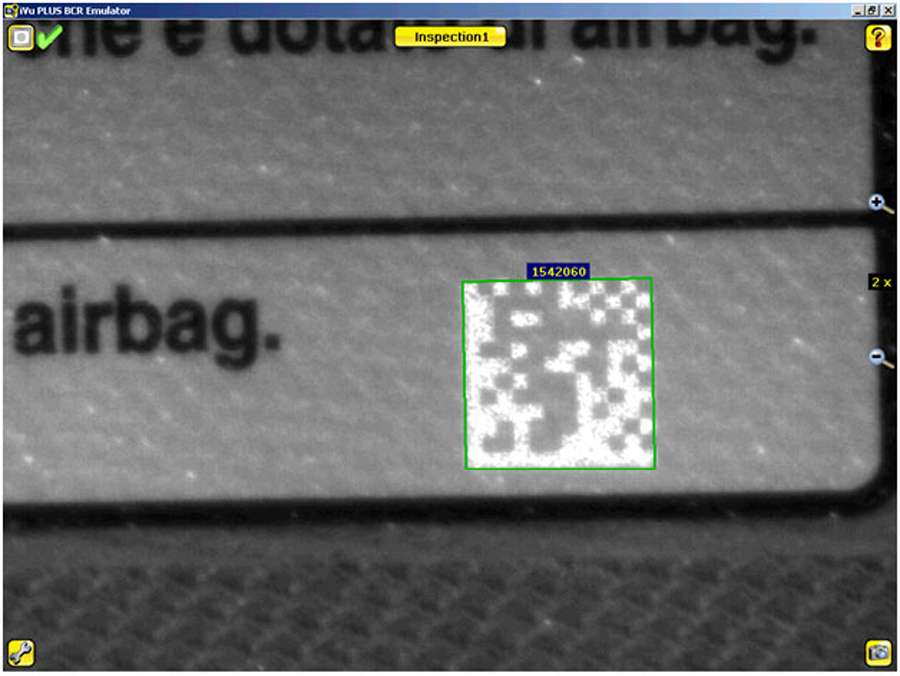

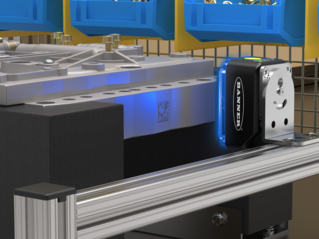

- In this application, an iVu BCR barcode reader with a C-mount lens, UV spotlight, and Ethernet capabilities can be used to read invisible 2D Data Matrix codes and send data via EtherNet/IP to a PLC for error proofing and traceability.

Track and Trace for Pharmaceutical Packaging

- Traceability is only effective for facilitating recalls if the correct codes are attached to the correct products. Therefore, validating codes prior to shipment is critical.

- In the pharmaceutical industry, medical supplies are often individually packaged in sealed pouches.

- Before product can be shipped, the barcodes must be validated to ensure that the correct barcode is affixed to the correct product for accurate traceability.

- An imager-based barcode reader validates each barcode and sends data via Ethernet IP to a PLC for future reference in case of recalls.

Imager-Based 1D and 2D Barcode Reader

ABRシリーズのバーコードリーダーは、最も困難な追跡用途を解決するための優れた解読機能を提供しています。2つのコンパクトなフォームファクタ、複数の照明構成、さまざまな解像度、多数のレンズオプションが用意されています。

- 1次元と2次元バーコードのフルライブラリの読み取り

- 産業環境で使用できるように最大IP67等級を備えた2種類のコンパクトなフォームファクタ

- あらゆる用途に対応する、最大2MPでの解像度と、複数の照明構成、およびオートフォーカスを含む複数のレンズ焦点距離

- DPMコードの読み取りや偏光ウィンドウなどの困難な用途に対応したモデル

- オンボードのプッシュボタンまたはPCの全機能搭載バーコードマネージャーを使用して、数分で構成

- ソフトウェアで調整可能なオートフォーカスを含む汎用性の高いレンズオプションにより、セットアップと構成を簡略化

- 産業用イーサネット、シリアル、USBを介して構成できるため、装置の統合を簡略化でき、IIoTデータの収集を実現

- あらゆるネットワークからリモートで統計情報を監視、構成、レビューできるWebインターフェイス

Imager-Based 1D and 2D Barcode Reader

iVu BCRシリーズ バーコードリーダーは、強力な解読機能と使いやすさを兼ね備え、困難なトレーサビリティ用途を解決します。汎用性の高いこれらのバーコードリーダーは、広範なレンズ、照明、およびユーザーインターフェイスで利用可能です。

- 破損コード、歪みのあるコード、その他の読み取りにくいコードなどを含む、広範な1Dおよび2Dバーコードの読み取り

- 複数のバーコードを向きに関係なく1回の検査で読み取り可能

- 統合されたタッチスクリーン、リモートタッチスクリーン、またはPCインターフェイスを使用して、検査の設定、管理、監視を実行

- 装置の統合を簡素化し、IIoTデータの収集を可能にするイーサネットおよびシリアル通信プロトコル

- 狭いスペースや産業環境に最適なIP67等級の堅牢なハウジング

- 豊富に用意された統合照明オプションにより、設置とコントラストの最適化にかかる面倒を軽減

- あらゆる用途のニーズを満たす、多様な標準およびCマウントオプションを含む交換可能なレンズ

TCNM Series

Laser-Based 1D Barcode Scanner

TCNMセンサーは、一般的に使用されている10種類を超える線形バーコード記号を解読でき、高速読み取り速度、広い被写界深度、高解像度を備えています。

- 10種類を超える一般的な線形バーコード記号を解読

- 500~1,000スキャン/秒で実行

- スマートティーチ押しボタンとLEDインジケータを使用した基本セットアップと診断操作

- 複数のスキャンを組み合わせて破損したコード情報を再構築する、コード再構築アルゴリズム

- マルチセンサーセットアップで外付けマルチプレクサーの必要性を排除する、GeniusPlusソフトウェアと専用イントラセンサー通信プロトコル

- 頑丈なIP65ハウジング