High Speed Sensing Applications

Maintain High Throughput and Quality

Manufacturers must keep lines moving quickly in order to meet production goals and maximize efficiency. However, very high speed applications can be challenging for the sensors that verify part presence, inspect part quality, count parts, and more.

In material handling and logistics, maintaining efficiency without sacrificing quality and accuracy is also critical.

To ensure quality in high speed processes, facilities depend on reliable detection and measurement solutions that can keep pace.

High Speeds Plus Challenging Targets

- Many high speed applications also include extremely challenging targets, including clear, reflective, multicolored, and extremely objects.

- In some cases, the application may require extremely precise measurement of challenging targets at very high speeds.

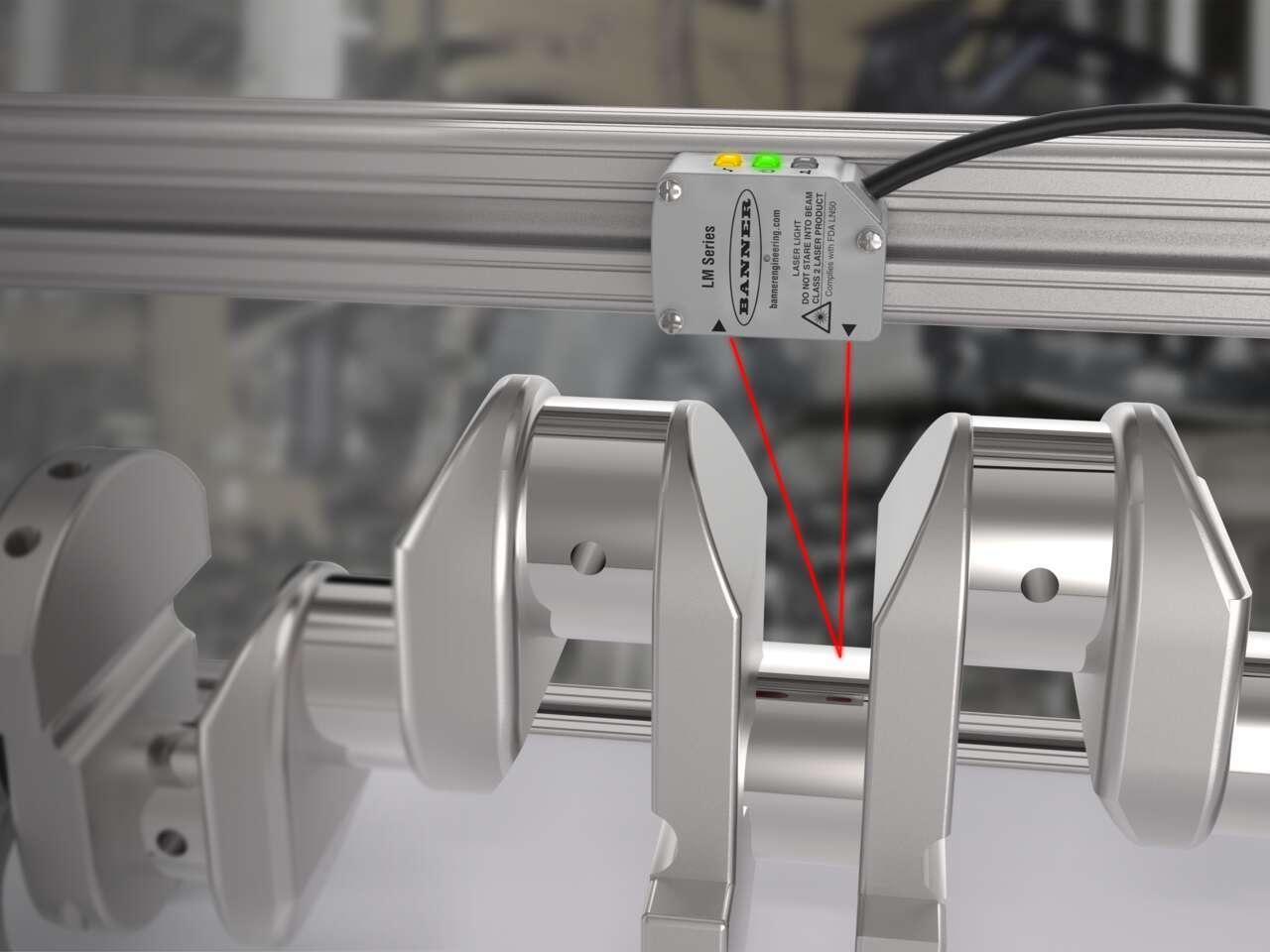

- For example, in automotive manufacturing, crankshaft runout measurements must be monitored continuously to ensure that they meet tolerance requirements. The reflective surface of the crankshaft and the high speed and precision of the application can be challenging for sensors to measure reliably. Learn how the LM Sensor solves this challenge.

- Banner offers a variety of sensing solutions for the most difficult high speed applications. See example solutions below or contact us to discuss your application.

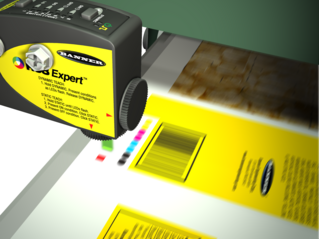

Registration Mark Detection

Packaging Industry

- Primary packaging has many high-speed processes, and it is important to verify correct packaging, which can be done by detecting registration marks.

- White registration marks on dark backgrounds, such as blue, can be challenging to detect at high speeds since many sensors are not able to maximize contrast for reliable detection of the mark and not the background.

- Banner Engineering's Q3X versatile, rugged laser contrast sensor is ideal for detecting registration marks. With a range up to 300 mm, the Q3X has a tight laser spot able to detect a small white registration mark reliably.

High Speed Tablet Counting

Pharmaceutical Industry

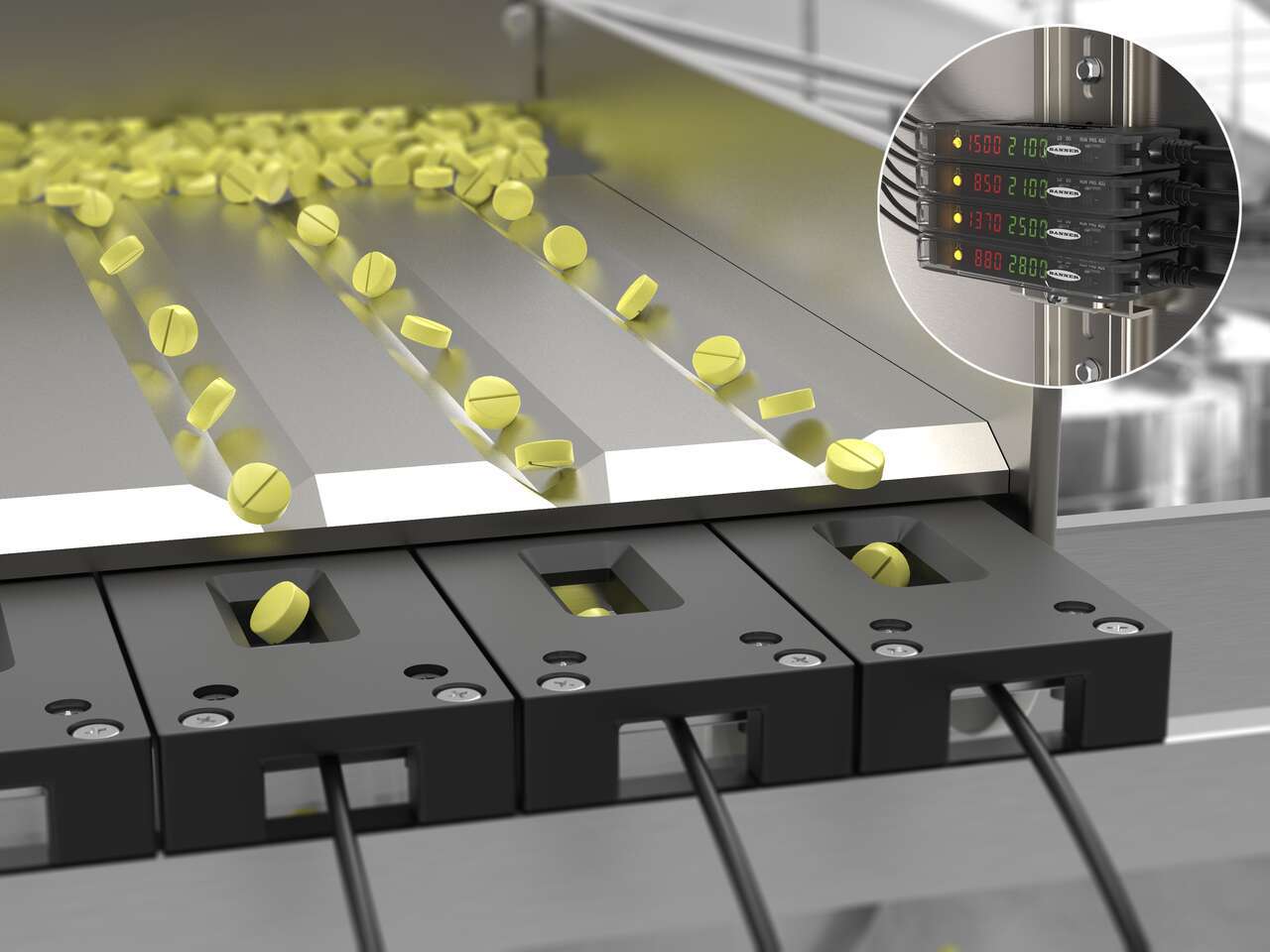

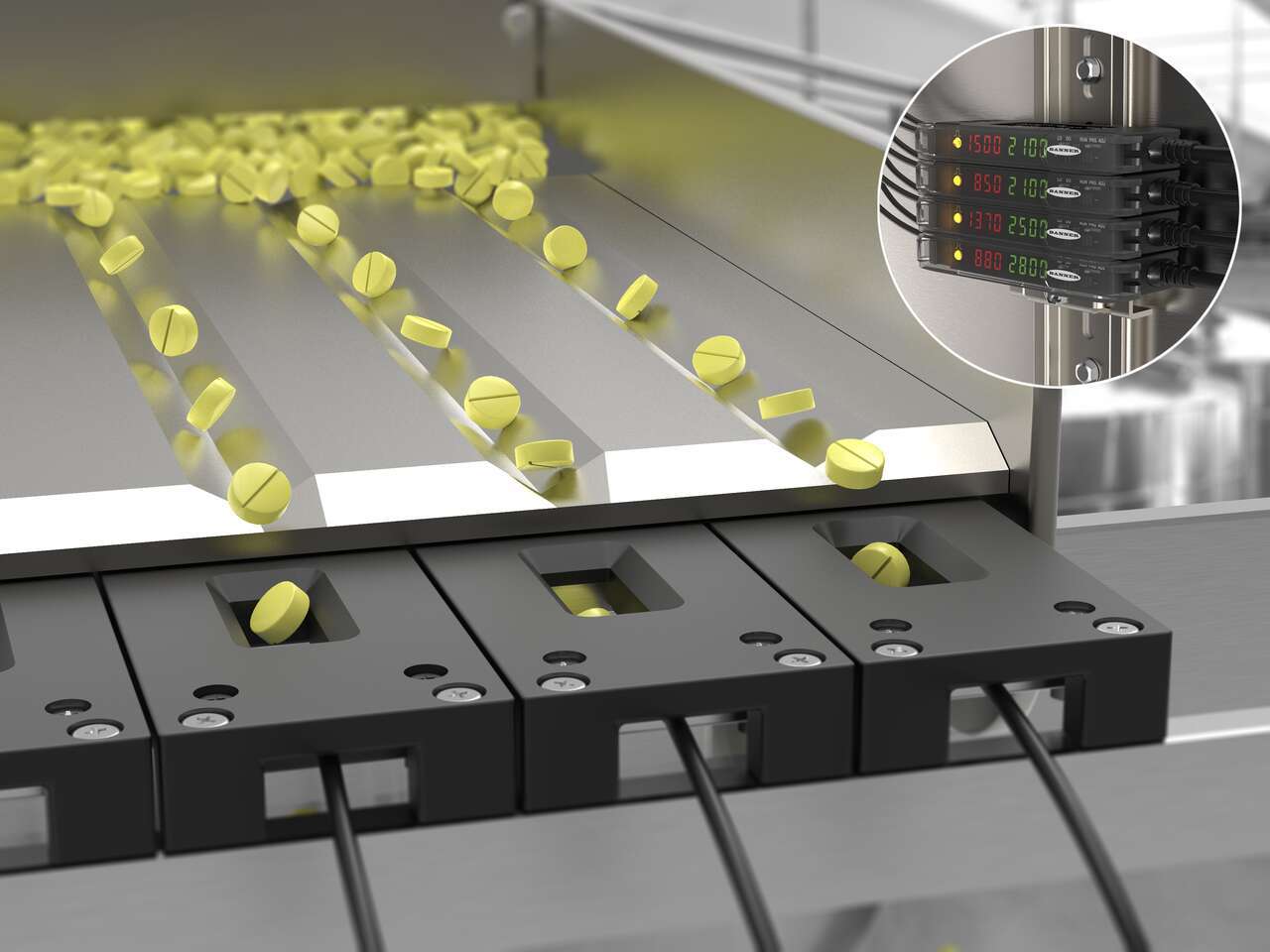

- In pharmaceutical packaging, products such as tablets, capsules and gel caps need to be accurately counted to achieve the proper number of tablets in each bottle.

- Pharmaceutical and medical industries use a dispensing mechanism to ensure the tablets separate from one another and don’t fall into the bottle side-by-side or simultaneously.

- All of this is done very quickly, creating the need for a high-speed, small-object counting sensor that can ensure tablets are accurately dispensed.

- The DF-G2 fiber optic amplifier is designed for high speed applications and can achieve 10 microsecond response time with 5 microsecond repeatability.

High Speed Box Profiling

Material Handling Industry

- Sorting parcels and packages prior to delivery is an essential step in shipping and handling.

- Order fulfillment applications rely on accurate automated sorting to keep costs down, maximize efficiency, and accommodate large volumes of packages during peak shipping seasons.

- To reduce the risk of error, an automated profiling solution is necessary to scan packages to ensure accurate—and fast—sortation.

- LE Series laser measurement sensors are an ideal solution to this applicaiton due their fast 5-10 millisecond response speed and ability to reliably detect any target, regardless of size, color or reflectivity.

DF-G2 Series

High Speed Fiber Optic Amplifier

DF-G2光ファイバー増幅器は、世界最速の応答速度を実現できるようデザインされており、10マイクロ秒の応答速度、5マイクロ秒の繰り返し精度を達成できます。

- IO-Link機能付きのモデルではリモートによる監視と構成が可能

- 10 μs、15 μs、50 μs、250 μs、500 μs、1000 μsのクラス最高の応答速度

- 読み取りやすいデュアルデジタルディスプレイに、信号レベルとしきい値を表示

- ディスプレイとスイッチ/ボタンまたはリモート入力ティーチワイヤを介して簡単にセンサをセットアップおよびプログラム設定できる単純なユーザーインターフェイス

- エキスパートティーチと設定により、すべての用途、特に高速または低コントラスト用途に最適なゲインとしきい値を確保

- 耐熱性の電子装置が起動時間を短縮し、運転中に信号の安定性を維持

LE Series

Laser Measurement Sensor

LEシリーズのリニアアレイ技術は、検出体の色や光沢に関わらず、優れたパフォーマンスと解像度を提供します。

- 設定不要ですぐに測定

- 2行8文字の直感的なディスプレイで簡単に調整

- リニアアレイにより、難しいターゲットでも繰り返し精度と精度を提供

- スポットサイズが小さく、アライメントが簡単な視認性のあるレーザー

- IO-Linkモデルも用意

H2