Level Measurement

Accurate Level Measurement Saves Costs

Accessing accurate level data from containers, hoppers, and tanks is critical to managing inventory, securing contents, assuring quality and safety, and saving costs.

Banner solutions for measuring and monitoring fill and material levels are available in a range of sensing technologies to optimize detection for each unique target and environment.

Used in combination with our wireless products, these solutions provide accurate, real-time data from assets deployed in remote and hard-to-access areas.

Reliable level detection is critical for a wide range of applications. For example, a dependable level measurement solution can:

- Ensure material is not wasted in spills due to overfill, which saves time and costs.

- Protect equipment from damage due to underfilling

- Prevent unplanned downtime and keeps processes moving along smoothly by predicting when containers will run out and enabling them to be refilled in a timely manner.

- Ensure customers and end users receive the correct amount of product, which improves customer satisfaction.

However, level measurement can be challenging due to the wide variety of materials, the location of containers, mounting contstraints, and more.

From precise measurement solutions to wireless solutions for remote tank level monitoring, Banner Engineering offers a variety of technologies to match your level measurement application. See a few examples below, or contact us to discuss your specific application.

Measure Level of Material in a Stack

- An accurate sensor is needed to monitor the stack height of the carton blanks in the magazine to ensure the stack is not empty and prevent downtime.

- A smart sensor, like the Q4X sensor, can accommodate changes in carton size and machine speed to help reduce downtime for setup and changeovers.

- The analog output provides a real-time gauge of the stack height. This allows the cartoner machine to have several “call for parts” set points without having to manually move the sensor.

- With exceptional linearity and a four-digit display, the Q4X sensor provides real-time feedback with an analog (V or mA) or distance (mm) readout.

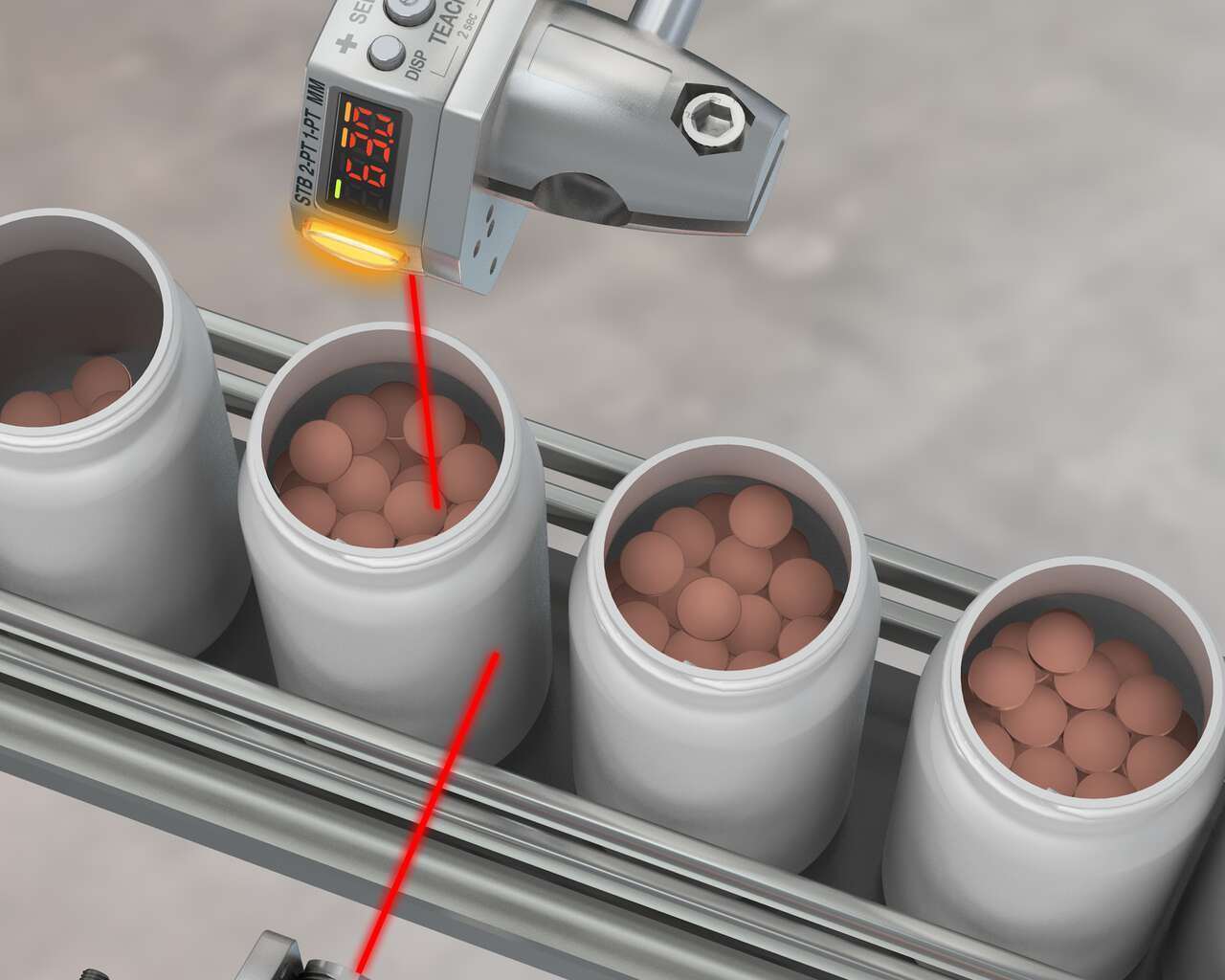

Monitor Level of Material in a Hopper

- For long-range level detection applications, an LTF Series laser measurement sensor can be installed up to 12 meters away from the target

- At this distance, the sensor will not interfere with system operations or come into contact with the equipment or process.

- The sensor features high excess gain, superior signal control and automatic adaptive laser power control for reliable detection, regardless of surface color or reflectivity.

- The exceptional linearity, repeatability and resolution of LTF series sensors ensure tremendous accuracy in measuring the distance from the sensor to the material in the hopper.

- The laser sensor can be paired with a TL50 Pro tower light to provide dynamic status indication of hopper fill level, for monitoring at a glance even from a distance.

Monitor Liquid Levels in Tanks

- Storage tanks, totes, and containers can be found in a wide variety of environments, from indoor or outdoor installations to above or below ground deployments.

- Properly monitoring and managing levels inside these tanks can help increase productivity and profitability.

- A wireless ultrasonic sensor uses sound waves to detect objects, for a non-contact level measurement solution.

- Ultrasonic sensors are also immune to target color, reflectivity, or transparency.

- Wireless communications open up additional benefits including saved time and costs, real-time remote monitoring, and adaptability to meet changing requirements.

Laser Measurement Sensor

LEシリーズのリニアアレイ技術は、検出体の色や光沢に関わらず、優れたパフォーマンスと解像度を提供します。

- 設定不要ですぐに測定

- 2行8文字の直感的なディスプレイで簡単に調整

- リニアアレイにより、難しいターゲットでも繰り返し精度と精度を提供

- スポットサイズが小さく、アライメントが簡単な視認性のあるレーザー

- IO-Linkモデルも用意

LTF Series

Long Range Laser Measurement Sensor

高性能LTFシリーズ センサーは、色や材質や光沢に関わらず、垂直でも斜めからでも最大24 mの距離からターゲットを検出します。

- 測定および検出用途に使用できるアナログおよびディスクリート出力またはデュアルディスクリート出力

- 検出範囲、繰り返し精度、および精度を最高レベルで組み合わせることで、極めて確実なターゲット検出と正確な距離測定を実現

- 2行8文字表示のディスプレイと押しボタン操作により、設定、トラブルシューティング、およびリアルタイム距離測定を簡単に実施

- 頑丈なIP67ハウジング、周囲光への高い耐性、およびすべての温度における安定したパフォーマンスにより、困難な環境においても確実な性能を発揮

- 遅延タイマー、高度なトリガ測定モード、およびクロストーク回避などの高度なオプション

- リモート構成と監視を行い、配線、予知保全、および装置の交換を簡略化するIO-Link通信モデルを用意

- リモートセンサディスプレイ (RSD) を使ったリモートプログラミング・監視