Order Fulfillment with Pick-to-Light

Improve Customer Satisfaction with Fast, Accurate Order Fulfillment

Order fulfillment refers to the process of receiving, processing, and delivering orders to end customers. A critical step in this process is ensuring that orders are picked from the shelves correctly and efficiently.

Quick, accurate picking increases customer satisfaction by ensuring that customers receive the correct item(s) on time. Banner Engineering offers a variety of light-guided picking solutions to match your application.

Getting the Right Order On Time Has Never Been More Challenging, or More Critical

In the age when almost anything can be delivered directly to a customer's doorstep, reliable order fulfillment systems are a must. Customers expect their orders to be correct and be delivered quickly—sometimes in as little as a few hours.

Fulfilling large volumes of orders quickly, especially with a high mix of inventory and little margin for error, can be extremely challenging. Fully manual processes are prone to human error; however, light-guided order picking is a cost-effective solution that helps workers quickly and accurately identify the correct order.

Choose a Versatile, Scalable Solution

- For larger scale applications, a pick-to-light solution must feature fast response speeds to accommodate many pick points without lags.

- The new PTL110 pick-to-light devices from Banner are powered by PICK-IQ™, a purpose-built, Modbus compatible serial bus protocol that uses a Common ID to reduce the typical latency that results from polling multiple devices.

- A fast response speed at scale is ideal for fulfillment stations that require many pick points while maintaining a rapid pace to exceed productivity targets.

Put-To-Light Solutions Reduce Errors Downstream

- Picking activities are only effective if the right inventory is in place and ready to be picked.

- Because of this, fulfillment centers require an efficient method for putting inventory on the shelves so that orders will be easily accessible during fulfillment.

- Put-to-light solutions improve the efficiency and accuracy of stocking activities and can help prevent downtime by reducing delays due to misplaced or incorrect orders.

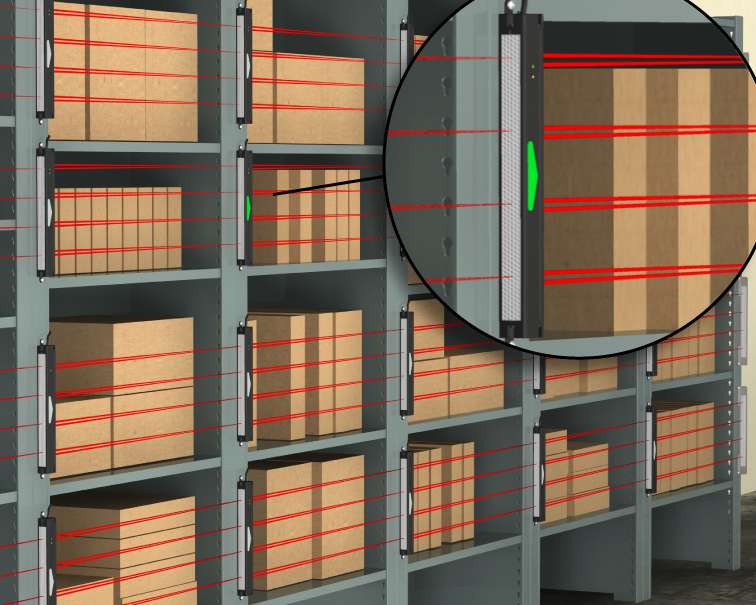

Optical Sensors Verify Pick Accuracy

- Pick-to-light devices with optical sensing capabilities can be used to check picks for accuracy in real time.

- These devices detect when a hand reaches into a shelf to pick a package and breaks the sensing beam or array.

- When picks are executed correctly, yellow LEDs confirm that the operator picked from the right location on the shelf.

- If the operator reaches into an incorrect shelf, a light turns red indicating an error.

Scalable, Versatile Pick-To-Light Devices

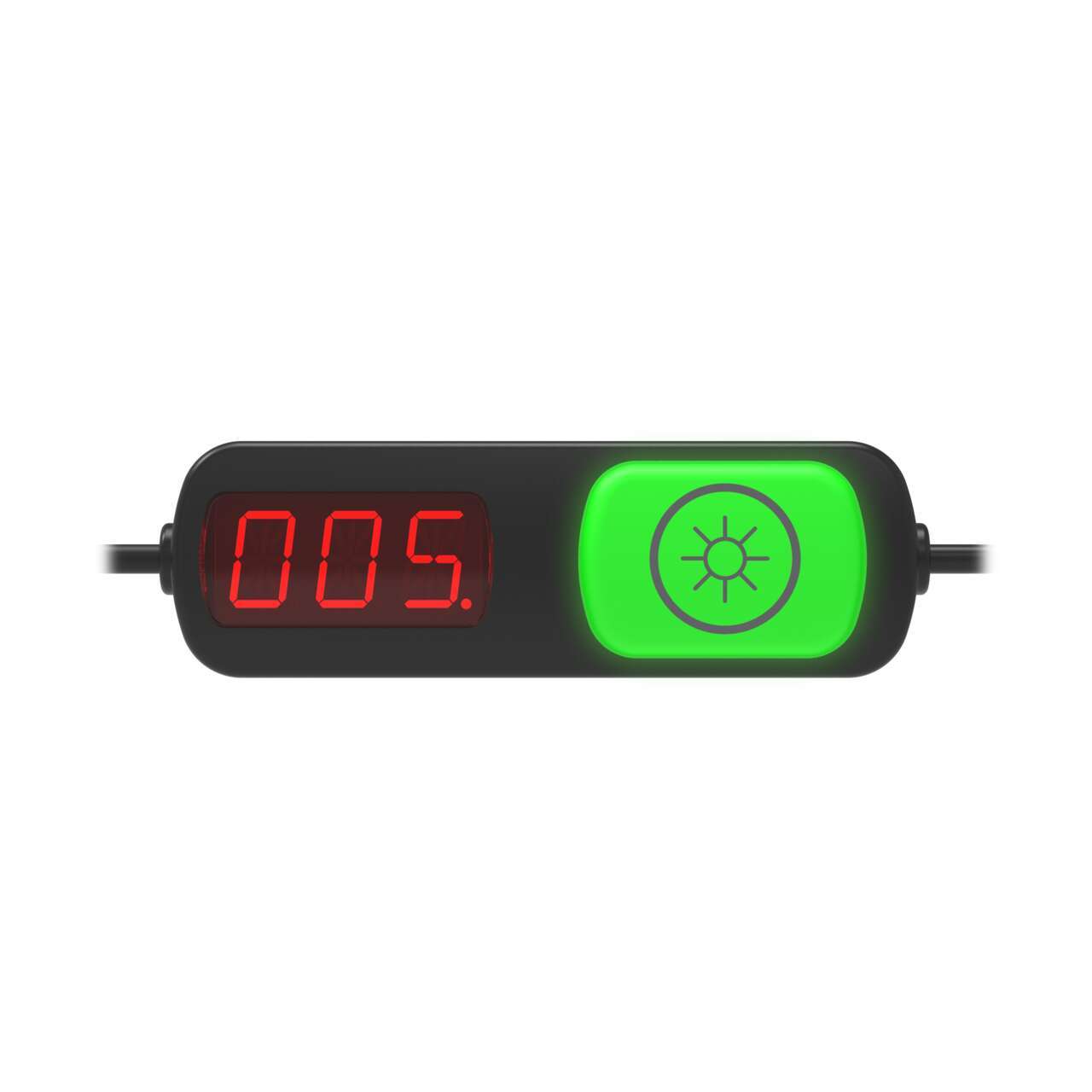

PTL110ピックトゥライト装置は、タッチボタン、光学センサ、3桁表示のオプションを備えた多機能インジケータで、連続して接続することにより、強力なピッキングシステムを作り出すことができます。高速応答時間と柔軟な設置オプションを特徴とするPTL110システムは、ピッキング、キッティング、および関連用途における速度、生産性、および品質の改善に役立ちます。

- 光学およびタッチセンサ機能付きのモデルを提供。

- オプションの英数字3桁表示のディスプレイにより、部品カウントやその他の指示を表示可能。

- ケーブルを追加することなく、複数の装置を素早く確実に設置できるM12コネクタ。

- インジケータには14色による多様な照明パターン機能が備わっているため、さまざまな状態を区別可能。

- Common IDを使って複数の装置のポーリングにより発生する一般的な遅延を軽減する特殊なModbus互換シリアルバスプロトコル PICK-IQ™ を使用。

- DXM700ワイヤレスコントローラとペアリングすることで、カートや可動式ピッキングステーションでの実装が可能。

Pick-to-Light Devices

Pick-to-Light Devices

A smaller version of the K50 Series, the K30 Pick-to-Light Series combines a bright indicator light with solid-state, touch-activated switching.

- Ergonomic design requires no physical pressure to operate, preventing stress on hands and wrists

- Simple operation with the touch of a finger

- Easily actuated with bare hands or work gloves

- Rugged, fully encapsulated IP69K construction for high-pressure wash-down environments

- Ideal for pick-to-light and call button applications in a variety of industries

- 1- and 2-color models available to solve a range of application