Tank Level Monitoring

Predictive Maintenance for Tanks

Storage tanks, totes, and containers can be found in a wide variety of environments, from indoor or outdoor installations to above or below ground deployments.

Properly monitoring and managing levels inside these tanks can help owners and asset managers increase productivity and profitability.

Keep reading to learn more about the benefits of a wireless solution for tank level monitoring.

There are many technologies to choose from that vary in terms of accuracy, reliability, and costs. Visual inspections and measuring sticks may be relatively inexpensive, but they are labor-intensive and prone to error because they rely on manual reporting methods.

More accurate tools, like floats and submersible pressure transducers, are not dependent on human labor to measure levels, which can simplify processes and minimize the risk of error. However, in some applications, a non-contact solution is preferable (for example, when measuring the level of caustic liquids).

A wireless ultrasonic sensor is a great choice for applications where a non-contact solution is needed. These sensors use sound waves to detect objects, so they do not need to come into contact with the materials they are measuring. They are also immune to target color, reflectivity, or transparency. Wireless communications open up additional benefits including saved time and costs, real-time remote monitoring, and adaptability to meet changing requirements.

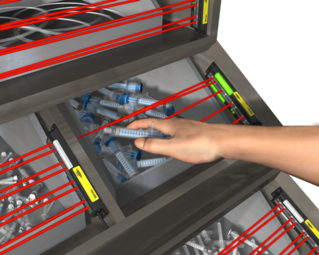

Quick Commissioning Without Costly Cable Runs

The infrastructure changes required in a wireless system are minimal, far easier, and less costly to implement than a wired system.

In a basic setup, a wireless node is connected to a measuring device, like a wireless ultrasonic sensor, and installed on the container. Each node in the network is bound to a wireless gateway or controller with an integrated gateway. Next a site survey is conducted to verify the connection between the deployed nodes and the gateway.

The system is then configured, and inspection parameters and alarm thresholds are set. A system like this can monitor many containers and can be set up in a fraction of the time and at a much lower cost than a wired system.

Improve Efficiency with Real-Time Alerts

With connected devices, asset managers can easily access tank level data in real time. improving both efficiency and productivity. For example, with real time monitoring of remote containers, managers can strategically plan visits based on actual need instead of sending staff to a site based on forecasted expectations of container levels. This saves time and costs while ensuring that tanks are full and processes are running smoothly.

In addition, automated alerts can be setup to notify staff of potential issues, minimizing emergencies when a tank runs dry or overflows. A real-time remote monitoring system can alert personnel via text or email if tank levels are outside of the established thresholds, and it allows them to respond to these conditions before they become critical.

Maintain the Flexibility to Make Changes Quickly

Business needs can change over time and companies may need to add or move containers at a site to keep up with new demands. Wireless networks are versatile, scalable, and adapt easily to changing requirements. They are also flexible enough to monitor both fixed and portable assets.

With a wireless system, containers can be moved as often as needed without altering the system or disconnecting the measuring device, which means containers can be monitored even while in transit. New nodes from new containers can be integrated into the existing network, or a new network can be deployed to accommodate a new group of tanks without the time and labor commitments of altering a wired network.

Wireless Ultrasonic Sensor for Tank Monitoring

The Sure Cross® U-GAGE® K50U Ultrasonic Sensor works in a variety of environments to provide a measurement of the distance between the target and the sensor. It is designed to be used with a Banner Wireless Node or Multihop Modbus Radio, creating a cost-effective, easy-to-use wireless solution for monitoring mobile or remote tanks and totes.

- 標準レンジモデル (300 ~ 3000 mm 検出範囲) は多様な用途の内容物レベルの測定と監視に最適です。

- ショートレンジモデル (100 ~ 1000 mm 検出範囲) は小型の容器やスペースの限られた用途できわめて精度の高い測定を可能にします。

- 温度補正機能搭載

- 過酷な検出環境に耐える頑丈なIP67等級の設計

Wireless Controller for IIoT Applications

DXMシリーズ産業ワイヤレスコントローラは、イーサネット接続とインダストリアルIoT (IIoT) 用途を容易にするように設計されています。

- ISM無線を900 MHzとローカルワイヤレスネットワーク用の2.4 GHzで提供

- Modbus RTUをModbus TCP/IPまたはイーサネットI/Pに変換

- アクションルールとテキスト言語メソッドを使ってプログラム可能な論理コントローラ

- データロギング用のMicro SDカード

- 電子メールとテキストによるアラート

- セルラー接続用のセルモデム