Multicolored Targets and Product Changeover

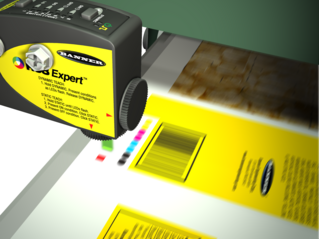

Multicolored targets are increasingly becoming the norm, especially in consumer packaged goods industries. The various types of packaging used include shiny, glossy, or other unpredictable surfaces.

For example, reflective, multicolored, and wrinkled material such as foil or film is frequently used in food and beverage packaging and can cause inconsistent sensor readings.

Multicolored targets are challenging for many sensors to consistently detect. This is because some colors, such as very dark colors, are more difficult for traditional photoelectric sensors to see because darker colors reflect back less light back to the sensor compared to lighter colors. Multicolored targets also have frequent color transitions and varying amounts of reflectivity that further impact sensing reliability.

Product changeover creates additional challenges because sensors must be able to reliably detect a variety of color combinations. To keep up with consumer demand, manufacturers require flexible sensing solutions that can detect all colors and that can be quickly updated with each new "recipe" during product changeover to keep production lines moving.

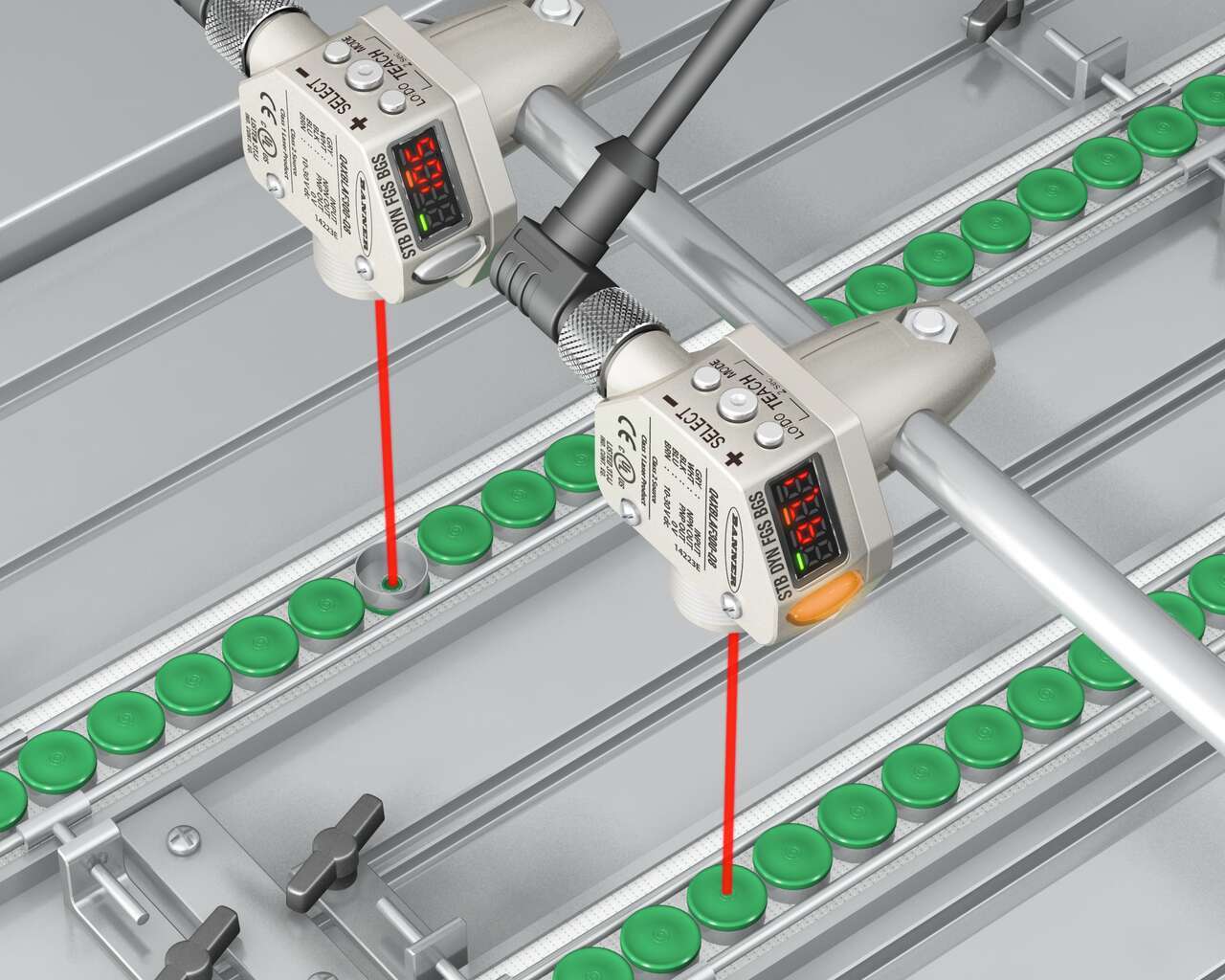

Laser distance sensors are an excellent choice for detecting multicolored packaging because cause they determine target presence or absence using distance. Laser distance sensors are unaffected by color transitions, and they can reliably detect all different varieties of packaging, regardless of color or reflectivity.

In addition, many laser distance sensors from Banner Engineering feature exceptionally high excess gain to reliably detect very dark colors, as well as automatic gain adjustment to dynamically increase or decrease sensing power depending on target reflectivity.

With IO-Link, users can easily read and change device parameters through the control system software, enabling fast configuration and commissioning that saves time and resources.

In addition, IO-Link sensors can accommodate multiple recipes that can be quickly and dynamically changed from the control system as needed—such as in the case of product changeover. For example, a line that runs products of different sizes at different times will require changes to sensors’ distance thresholds.

Manufacturers use many terms to describe sensor performance, but not all manufacturers use the same specifications, which can make it challenging to compare different models of sensors. Read the article to learn tips for choosing the right sensor for any application.

Laser Distance Sensor with IO-Link, 25-610 mm

より高いパフォーマンスとミリメートル未満の距離の変化を検出できる能力を持つ、多用途性に優れた頑丈なレーザー距離センサです。

- ディスクリート、アナログ (0~10Vまたは4~20 mA)、透明体、およびIO-Linkモデル

- 25 mmから610 mmの確実な検出範囲

- 様々なターゲットの色、材質、および表面を距離に基づいて検出

- エラー防止用途に最適なデュアルティーチモード (明暗度 + 距離)。反射板を使用せずに透明体を検出

- FDA級ステンレス鋼製、IP69K等級の堅牢なハウジング

Laser Distance Sensor with IO-Link, 9.5 cm to 2 m

Q5X背景抑制レーザーは、業界標準の長方形ハウジングを備えたコスト効率の良い強力なセンサで、あらゆる問題を解決します。

- レンジ 9.5 cm (4インチ)~2 m (6フィート6インチ)

- 類まれの高過剰ゲインにより、遮光性の非常に高い物体 (<_6 の反射性遮光ターゲット="の反射性遮光ターゲット" でも確実に検出="でも確実に検出" li="li">

- 遮光背景の遮光ターゲット、光沢性の金属背景の遮光ターゲット、透明体、反射体、多色包装、およびあらゆる色のターゲットを確実に検出

- 距離と光の明暗度の両方を測定するデュアルティーチモードにより、非常に困難な用途でも解決可能