Dynamic Status Indication

Clearly Communicate Advanced Statuses

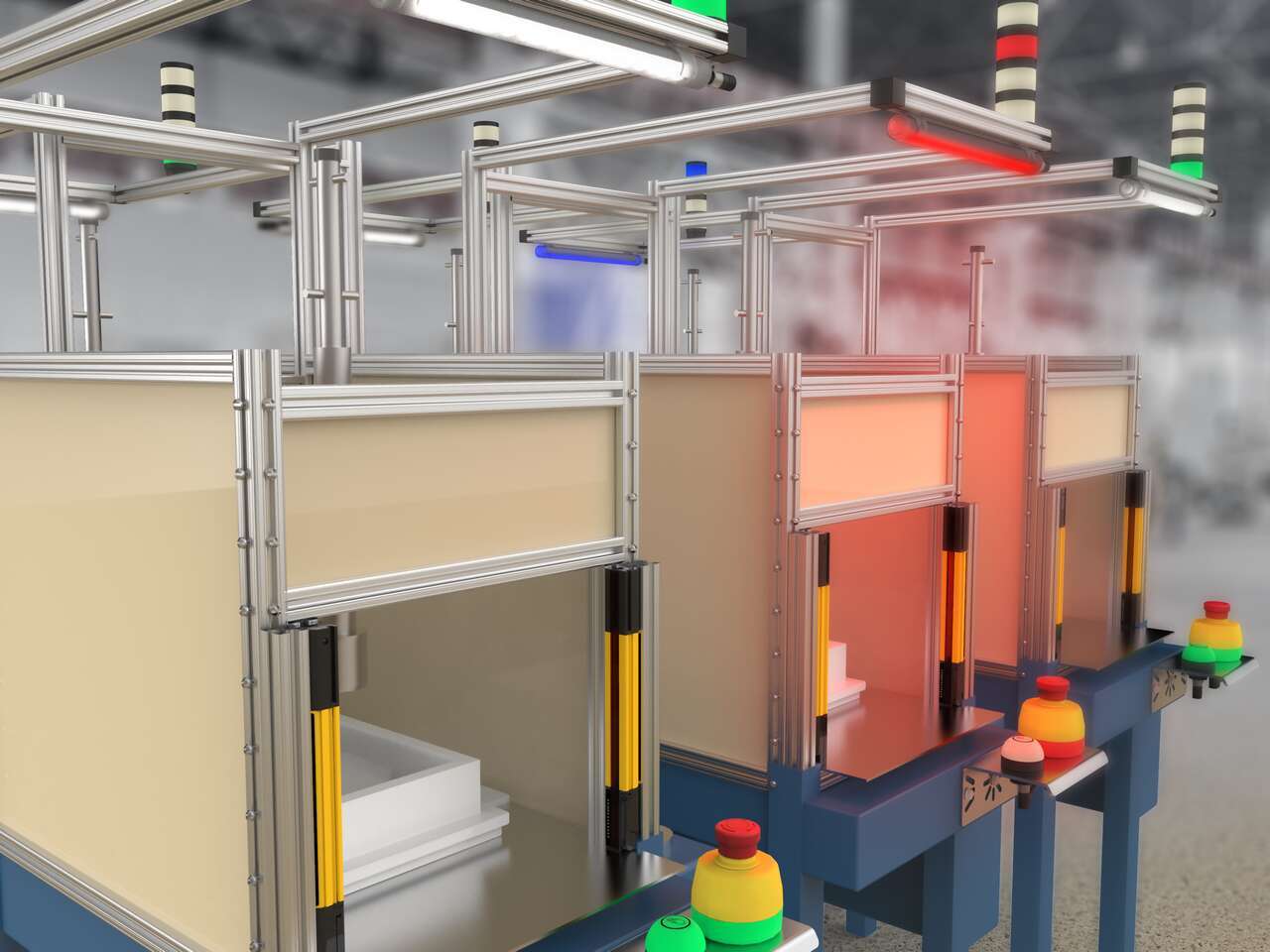

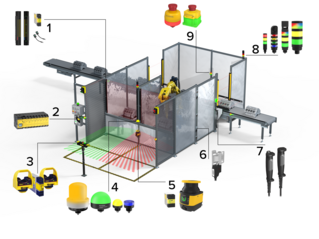

Indicator lights have long been the visual language of machines. However, traditional indicators are limited—typically offering 3-5 colors to represent a wide range of statuses. Sometimes this palette isn’t enough to capture the complexities of modern machines and processes.

Programmable RGB indicators let you choose from a wider variety of colors and change them as needed. Many RGB indicators also come with pre-defined animations and advanced functions to expand indication possibilities and represent active machine statuses.

Get More Insight at a Glance

Dynamic statuses are machine or process conditions that are often challenging to convey with a traditional solid color or flashing light. Examples include machine warmup state, transitional states, takt time remaining, fill level, and more.

Advanced indication requires a broader spectrum of color options. More colors allow each status or assembly step to have a unique indication from other steps, eliminating confusion and speeding up interpretation of the signals.

Additional colors and animations also communicate advanced states visually and intuitively for operators and supervisors alike. They add nuance to the visual language of your machines, conveying more status information at a glance compared to traditional indicators.

Keep reading to learn more about indication solutions for dynamic machine statuses, or contact us to discuss your specific application.

Use Case: Machine Startup and Transition States

- Many machines have a “warm-up” period after being turned on before the machine is ready to go.

- With traditional indication, an indicator light might be off when the machine is off and then turn green when the machine is turned on. This can be confusing to an operator if the light is green, but the machine is still warming up.

- An indicator with a 2-color rotating animation mimics the “loading” icons used in PC environments and can indicate that the machine is working but not ready to start the next process.

- The animation can then turn to a solid light when the machine is ready to go. The operator then can easily identify the state of the machine.

- Operators can also spend warm-up time on other productive activities versus just waiting.

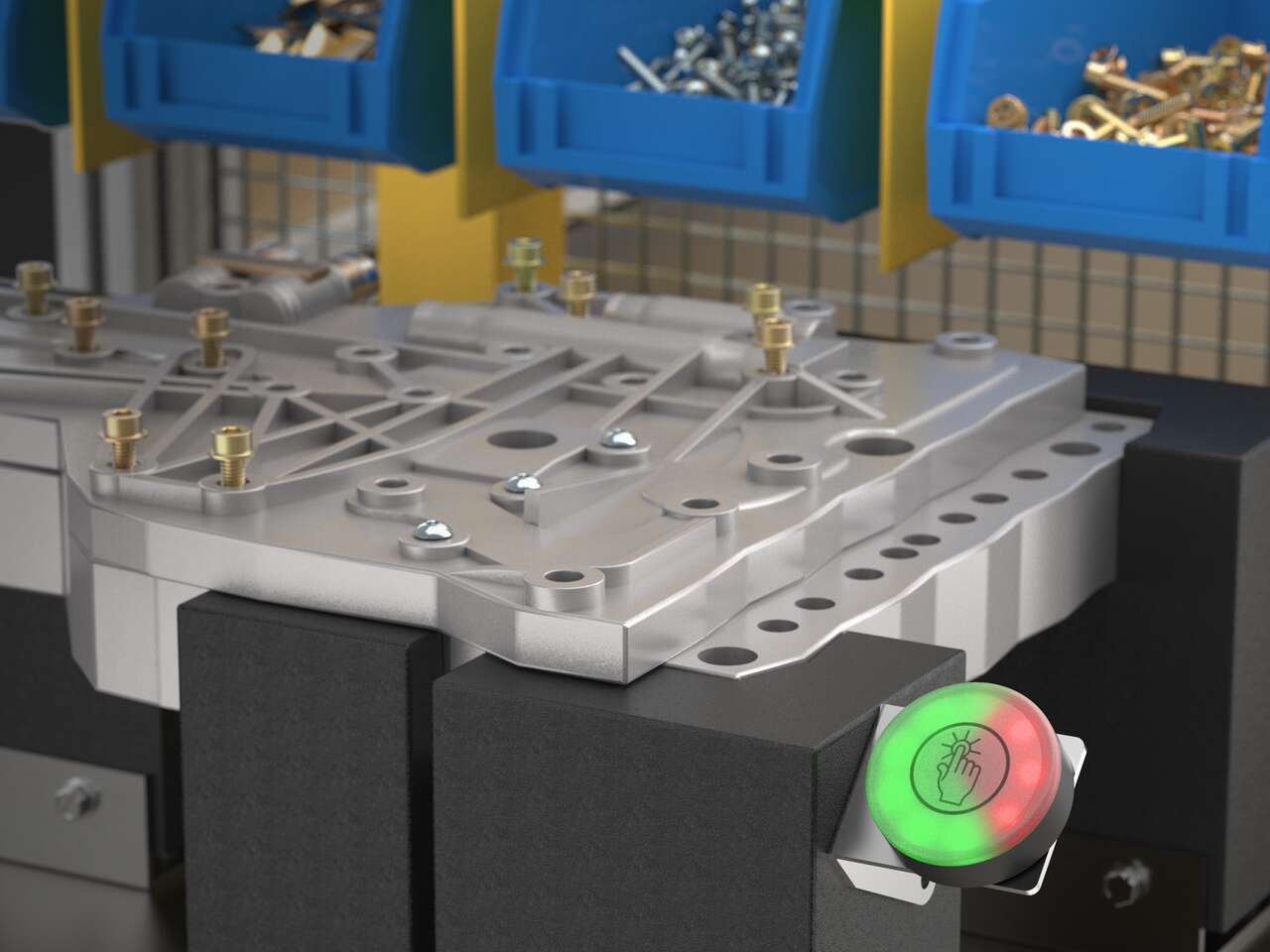

Use Case: Takt Time Indication

- Programmable LED touch buttons can be used to indicate takt time in assembly processes. This dynamic, visual feedback can help keep an assembler on track and aware of how much time has elapsed without having to look away from work.

- Takt time is important to manufacturers because it represents the rate of production that is needed to match demand and maximize profits.

- Using the IO-Link compatible K50 Pro touch button ensures operators are maintaining takt time.

- Sequence mode is included with IO-Link models and can be used as a timer. The bright LED lights are easy-to-see and installed directly in an assembler's sightlines for increased efficiency and less distraction from the task at hand.

Use Case: Tank Level Monitoring

- Operators, material handlers, and supervisors need to see the level of product in the hopper. However, local displays are not visible throughout the factory.

- The TL50 Pro tower light shows fill level through distinct, color-coded segments, and is visible from across the factory floor so operators can quickly respond to high or low-level alerts.

- The IO-Link master directly converts the laser measurement into an easy to understand fill level based on user-defined thresholds.

- Personnel can see the fill level status from a distance. In the event of an alert, the staff can identify whether the level is too high or too low, so they are immediately prepared to respond to the situation.

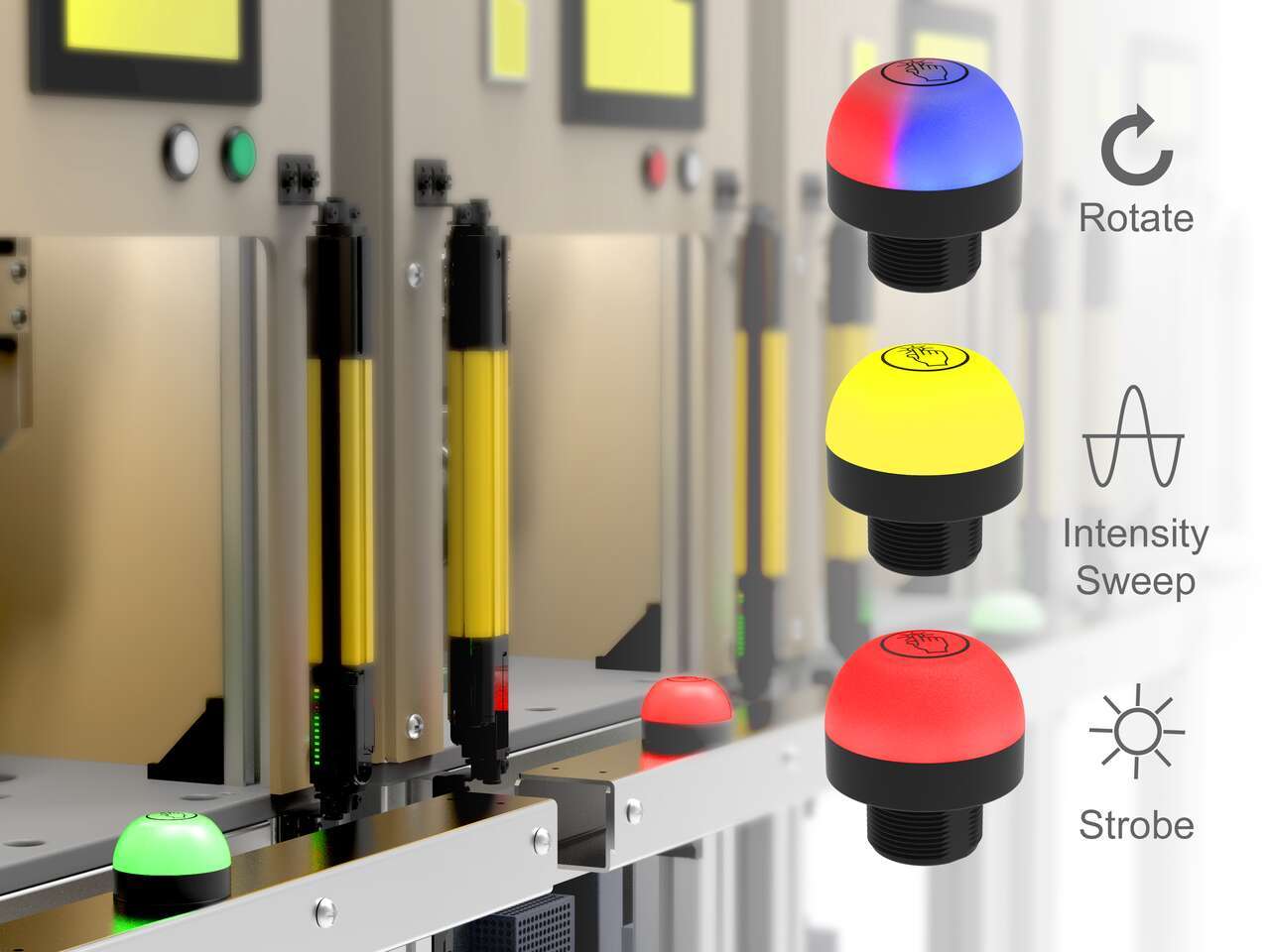

Programmable Multicolor Indicator

50 mmドームまたはフラットウィンドウ搭載のプログラマブル汎用インジケータは、より明確で明るくステータスを表示します。

- K50 Proシリーズのマルチカラーインジケータでは、色、点滅、減光のほか、回転、ストロボ、2色表示、2色回転、2色点滅、チェイスなどの高度な照明パターンを設定できます。

- Pro Editor対応モデルでは、ユーザーが既定の色を選択し、IO-Linkを使用せずに、現場で装置をプログラム設定することができます。

- IO-Link通信機能付きのモデルでは、ほぼ無制限に表示をカスタマイズできます。

- 現場でカスタマイズされるモデル数を縮小して標準化することで、コスト削減と在庫要件の縮小を実現

- IP66、IP67、IP69Kの頑丈なポリカーボネート製ハウジング

- セットアップを単純化し、コストを節減できるシンプルな配線計画

- オプションのブザーアラームにより、はっきりと大音量でステータスを通知

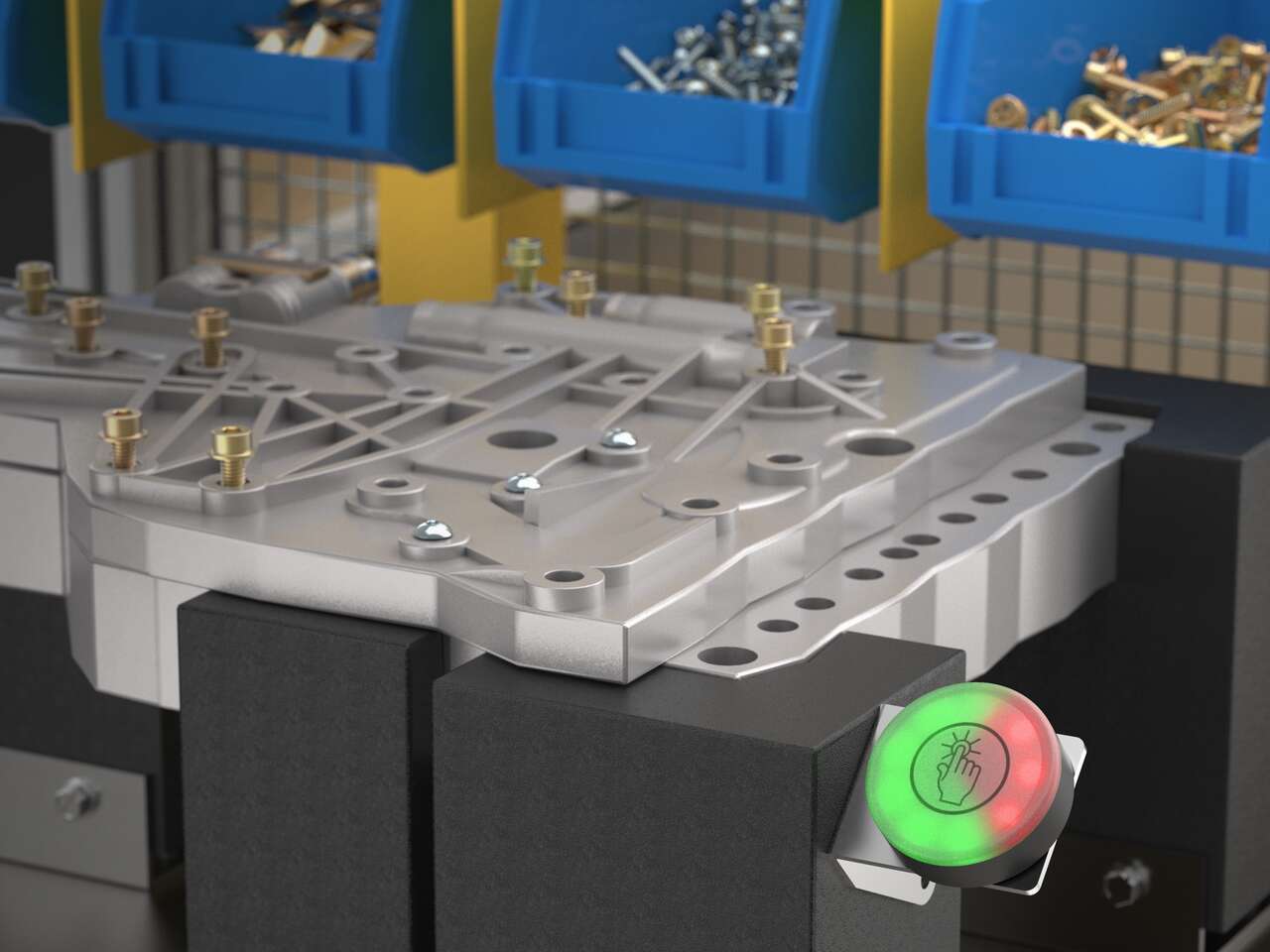

Programmable Multicolor Touch Button

K50 Proタッチボタンは、定評のあるタッチ技術と耐久性にRGB LEDの多用途性を付加したボタンです。

- タッチ作動式切り替え機能を備えた明るいLEDインジケータ

- 高圧洗浄環境に耐える頑丈なIP67およびIP69K構造

- 人間工学的設計により、操作に物理的圧力が不要で、手と手首へのストレスを緩和

- マスターによって動的管理が可能な全Pro機能搭載のIO-Link対応モデル、個別のLED制御によりステータスを完全カスタマイズ

- IO-Link対応モデルに含まれるシーケンスモードを使えば、レベルやタクトタイムなどを表示可能

TL50 Pro Series with IO-Link

Programmable Tower Light

幅広いカラーオプションを組み合わせることで、ほぼ無限ともいえるカスタム表示を実現する多用途のアンプ内蔵型タワーライト。これらのカラーオプションは、IO-Link通信によって可能になる動的制御機能が付いたRGB LEDにより提供されます。

- 頑丈でコスト効率が高く、設置が簡単

- パラメータとプロセスデータのオプションによる機能の完全な制御

- IO-Linkにより、色、点滅、回転、明暗度、さらに高度な照明パターンを完全に制御

- 高い視認性、一目でわかる操作指示とステータス表示

- 最大10のライトセグメントと追加のブザーセグメントをサポート

- 標準、密閉、または全方向式可聴要素のブザーモデル