Detecting Clear and Reflective Targets

Detecting transparent or shiny objects is one of the most challenging sensor applications. Variations in target shape, size, material, color, and translucence can complicate accurate detection. For example, the light from the sensor can burn through a target or be reflected away erratically.

Furthermore, not all clear and reflective materials attenuate light in the same way; for example, a glass bottle will attenuate light differently than a plastic bottle, and variations in the contours and grooves of a target can also cause light to reflect in unpredictable ways.

In addition, high speed conveyors and harsh washdown environments found in many clear object detection applications present additional challenges.

Two common technologies for clear object detection are: laser distance sensors and retro-reflective photoelectric sensors (photo-eyes).

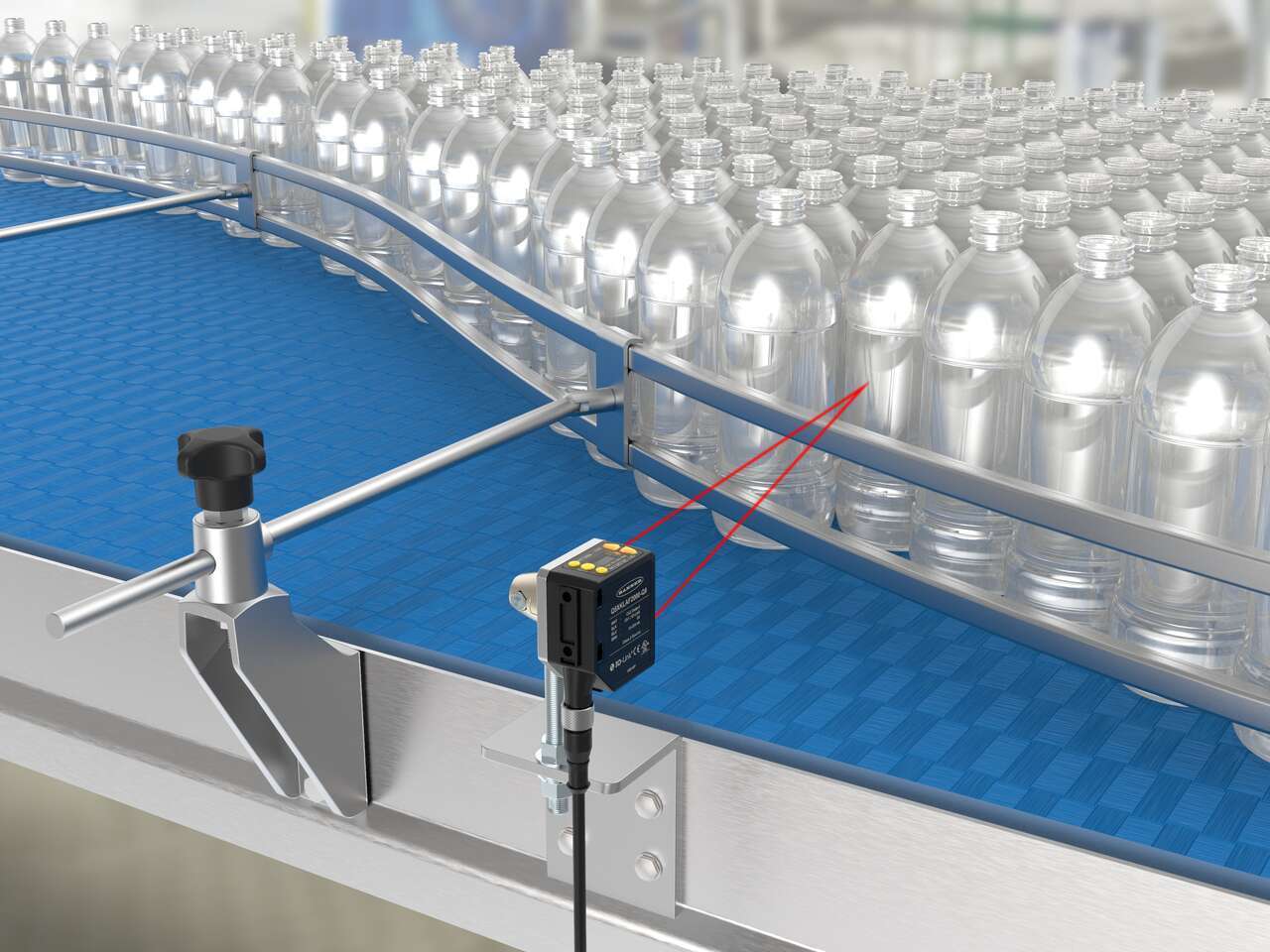

Laser distance sensors are an extremely effective solution for clear object detection, including detecting small targets. Laser measurement sensors with dual mode can detect changes in both distance and light intensity to reliably identify clear objects; these sensors do not require a reflector or receiver unit, which allows for flexible mounting as well as reduced inventory and maintenance costs. In addition, laser sensors are available with response speeds as fast as 0.5 ms for detecting fast-moving targets.

Depending on your application, you might also consider retro-reflective photoelectric sensors. A photoelectric sensor designed for clear object detection is often a cost-effective solution for detecting larger clear objects with larger gaps between them, where the precision of a laser sensor is not necessary. Similar to laser sensors, photoelectric sensors are capable of very fast response times for high speed applications. It is important to consider, however, that these sensors do require mounting a reflector.

Choose Laser Distance Sensors With Dual Mode

A premier solution for clear and reflective object detection is a laser measurement sensor with dual mode. The small, visible laser spot allows for easier sensor alignment, greater precision, detection of smaller objects, and detection of smaller gaps between objects compared to an LED-based sensor. In addition, laser sensors with dual mode do not require a reflector for more flexible mounting and reduced inventory and maintenance costs.

In addition to measuring distance, laser sensors with dual mode also detect changes in light intensity from a stable background condition. In other words, a laser distance sensor with dual mode can detect not only when the target is present within a certain distance but also when it returns a certain amount of light to the receiver.

For this to work, a stable reference surface must be taught, and the distance and intensity of the reference surface are recorded and used as a baseline. The presence of a transparent or highly reflective object entering the sensing range of the beam alters the perceived distance and light intensity from the background condition.

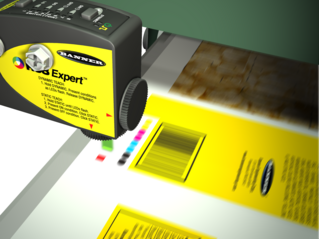

Choose Photoelectric Sensors with Polarized Coaxial Optics

Retro-reflective sensors are the most commonly used LED-based photoelectric sensor in clear object detection applications. Each sensor houses an emitter and a receiver. The emitter directs a beam of light to a reflector which redirects the light beam back to the receiver. An object passing between the sensor and reflector will either block or attenuate a perceivable percentage of the emitted light.

Retro-reflective photoelectric sensors with a coaxial optical design emit and receive light along a single narrow axis. This optimizes clear object detection by dramatically reducing the risk of false detection from reflected light. Sensors using this technology have a small bright spot that simplifies sensor alignment and enables precise leading edge detection.

Photoelectric sensors with polarizing filters will emit and detect light waves of a specific polarization, ignoring all other light waves. This further reduces the risk of false detection caused by reflected light. Learn more about polarized coaxial optics for detecting transparent objects.

Choose Sensors Rated IP69K

Many clear object detection applications occur in food and beverage processing applications, which are often subjected to frequent high pressure, high temperature washdown and/or chemical clean-in-place processes to ensure a safe food chain.

Sensors rated IP69K are ideal for these environments, as they have been tested to ensure reliable operation even when subjected to frequent cleaning. A rugged, stainless steel sensor is a popular choice, and in some applications, a sensor made with food-grade materials may be required. Learn more about IP ratings and what they mean.

In some cases, plastic sensors can also be used, as long as they are properly sealed. In addition, some photoelectric sensors can see through an aperature, which allows them to be shielded for use in washdown and hygienic environments.

IP69K Laser Distance Sensor, 25-610 mm Range

より高いパフォーマンスとミリメートル未満の距離の変化を検出できる能力を持つ、多用途性に優れた頑丈なレーザー距離センサです。

- ディスクリート、アナログ (0~10Vまたは4~20 mA)、透明体、およびIO-Linkモデル

- 25 mmから610 mmの確実な検出範囲

- 様々なターゲットの色、材質、および表面を距離に基づいて検出

- エラー防止用途に最適なデュアルティーチモード (明暗度 + 距離)。反射板を使用せずに透明体を検出

- FDA級ステンレス鋼製、IP69K等級の堅牢なハウジング

Laser Distance Sensor, 9.5 cm - 2 m Range

Q5X背景抑制レーザーは、業界標準の長方形ハウジングを備えたコスト効率の良い強力なセンサで、あらゆる問題を解決します。

- レンジ 9.5 cm (4インチ)~2 m (6フィート6インチ)

- 類まれの高過剰ゲインにより、遮光性の非常に高い物体 (<_6 の反射性遮光ターゲット="の反射性遮光ターゲット" でも確実に検出="でも確実に検出" li="li">

- 遮光背景の遮光ターゲット、光沢性の金属背景の遮光ターゲット、透明体、反射体、多色包装、およびあらゆる色のターゲットを確実に検出

- 距離と光の明暗度の両方を測定するデュアルティーチモードにより、非常に困難な用途でも解決可能

Photoelectric Sensor for Clear Object Detection

汎用ハウジング設計と18 mmスレッドレンズ、および数100もの様々なセンサに代わる理想的なセンサ。透明体検出モデルには埃の堆積や周囲温度の変化による影響を自動的に補正する「透明トラッキング」アルゴリズムが搭載されており、センサの信頼性と耐久性がさらに高まります。

- 18 mmスレッドレンズまたは側面取り付け型汎用ハウジング

- 数多くのセンサに取り替わる性能

- 過酷な環境に耐えるIP67およびNEMA 6規格

- 最大20 mの範囲

- 明るいLED動作ステータスインジケータ

- 明確な物体検出のために特別に設計されたCODモデル。