Food Traceability and Safety

Protect Public Health and Your Brand's Reputation

Product recall is costly not only in terms of lost revenue, wasted materials, and production time but also in terms of brand reputation and brand loyalty. The sooner food safety issues can be addressed and mitigated, the lower the risk of a large-scale recall.

When food safety recalls do occur, it is critical for companies to be able to remove all spoiled or contaminated products from the market as quickly as possible to limit the impact on public health.

Identification solutions for food traceability not only facilitate faster recalls when they occur, but can help prevent recalls by verifying products at every step.

Traceability in food and beverage industries is more important than ever before, which is primarily driven by growing consumer demand for visibility into the origins of their food. Also, allergies and sensitivities to specific ingredients, such as those containing gluten, necessitate proper labeling of packaged food products.

However, as traceability has become even more critical, it has also become much more complicated due to the highly matrixed and global nature of food and beverage supply chains.

A reliable identification application is a foundation for track and trace solutions to ensure that food is safe for consumption and that the source of the ingredients are validated for health- and environmentally-conscious consumers.

Explore the identification solutions below, or contact us to discuss your specific application.

Isolate Food Safety Issues with Detailed Tracking

- In food packaging, barcodes are embedded with information specific to each product and production run to identify products throughout the supply chain.

- As part of a track and trace program, a packing house verifies product barcodes at multiple points during packaging, creating a record that will allow the company to quickly identify and isolate any product with quality issues in the event of a recall.

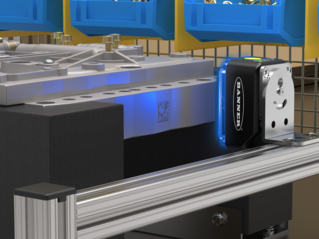

- Imager-based barcode readers, like the ABR 3000 from Banner, are capable of decoding the broadest range of 1D and 2D barcodes. Deployed along the packaging line, the ABR 3000 verifies that the barcode printed on each package is present, readable, and correct for each production run.

- The information contained in the barcodes is sent via an Ethernet connection to the company’s production management system which records the data for future reference.

Prevent Recall Due to Undisclosed Allergens

- Food allergies are potentially lethal to the consumer, so it is essential that food packaging accurately discloses the allergens present in the food item. By law, eight major foods must be disclosed on packaging: milk, eggs, fish, shellfish, tree nuts, peanuts, wheat, and soy.

- However, one error that can occur during the processing of packaged foods is when a product is placed in the incorrect packaging, resulting in inaccurate labeling of food contents.

- To prevent mislabeled product and ensure quality and food safety, the iVu barcode reader can determine whether the label pattern matches a reference pattern taught to the device.

- Automating label inspections with a reliable vision solution improves quality control by reducing the risk of error common to manual inspections, which in turn helps reduce the incidence of a product recall due to undisclosed allergens.

Choose Rugged, Water-Resistant Devices

- In food and beverage applications, identification devices like barcode readers are often near water, and other liquids used to keep surfaces clean and free from debris or other contaminants that can compromise food safety.

- In most cases, identification devices are unlikely to experience direct, high-pressure, high-temperature washdown.

- However, water may still come in contact with the devices, so water-resistance is essential to ensure that barcode scanners perform reliably and are not damaged.

- Depending on the application, an IP65 or IP67 rated housing ensures that the device will function reliably even when exposed to water.

Imager-Based 1D and 2D Barcode Reader

iVu BCRシリーズ バーコードリーダーは、強力な解読機能と使いやすさを兼ね備え、困難なトレーサビリティ用途を解決します。汎用性の高いこれらのバーコードリーダーは、広範なレンズ、照明、およびユーザーインターフェイスで利用可能です。

- 破損コード、歪みのあるコード、その他の読み取りにくいコードなどを含む、広範な1Dおよび2Dバーコードの読み取り

- 複数のバーコードを向きに関係なく1回の検査で読み取り可能

- 統合されたタッチスクリーン、リモートタッチスクリーン、またはPCインターフェイスを使用して、検査の設定、管理、監視を実行

- 装置の統合を簡素化し、IIoTデータの収集を可能にするイーサネットおよびシリアル通信プロトコル

- 狭いスペースや産業環境に最適なIP67等級の堅牢なハウジング

- 豊富に用意された統合照明オプションにより、設置とコントラストの最適化にかかる面倒を軽減

- あらゆる用途のニーズを満たす、多様な標準およびCマウントオプションを含む交換可能なレンズ

TCNM Series

Laser-Based 1D Barcode Scanner

TCNMセンサーは、一般的に使用されている10種類を超える線形バーコード記号を解読でき、高速読み取り速度、広い被写界深度、高解像度を備えています。

- 10種類を超える一般的な線形バーコード記号を解読

- 500~1,000スキャン/秒で実行

- スマートティーチ押しボタンとLEDインジケータを使用した基本セットアップと診断操作

- 複数のスキャンを組み合わせて破損したコード情報を再構築する、コード再構築アルゴリズム

- マルチセンサーセットアップで外付けマルチプレクサーの必要性を排除する、GeniusPlusソフトウェアと専用イントラセンサー通信プロトコル

- 頑丈なIP65ハウジング